In the field of material science, Polytetrafluoroethylene (PTFE) is a high-performance synthetic fluoropolymer, most famously known by the brand name Teflon. Its immense popularity for plastic bearings is rooted in one primary characteristic: an exceptionally low coefficient of friction. This property allows it to be self-lubricating, which, combined with its high resistance to chemicals and temperature, makes it an ideal material for creating smooth, durable, and maintenance-free components.

The fundamental reason PTFE is a preferred material for bearings is its self-lubricating nature. This eliminates the need for traditional grease or oil, resulting in cleaner, longer-lasting, and more reliable maintenance-free operation.

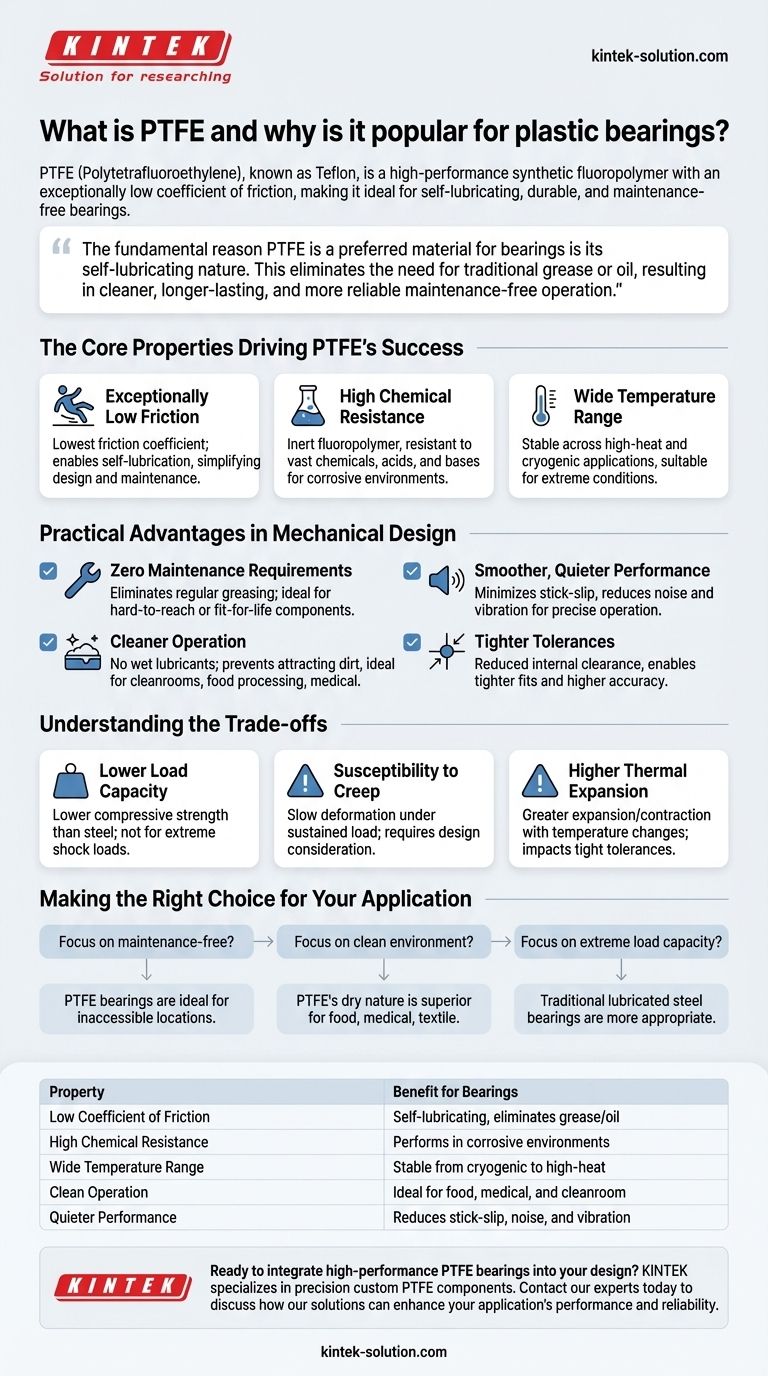

The Core Properties Driving PTFE's Success

To understand why PTFE is so effective, we must look beyond the surface and analyze the specific properties that make it a superior choice for demanding bearing applications.

Exceptionally Low Friction

PTFE has one of the lowest friction coefficients of any known solid material. This inherent "slipperiness" is the basis for its self-lubricating capability.

Instead of relying on an external lubricant like oil or grease, the bearing's motion is facilitated by the material itself. This dramatically simplifies design and reduces long-term maintenance.

High Chemical Resistance

PTFE is a fluoropolymer, making it incredibly inert. It is resistant to a vast range of chemicals, acids, and bases.

This property makes PTFE bearings invaluable in corrosive environments where a traditional metal bearing would quickly degrade and fail.

Wide Temperature Range

With a high melting point and stability across a broad temperature spectrum, PTFE can perform reliably in both high-heat and cryogenic applications.

This versatility allows it to be specified for machinery operating in extreme conditions, from industrial ovens to scientific equipment.

Practical Advantages in Mechanical Design

These core properties translate directly into tangible benefits that solve common engineering challenges.

Zero Maintenance Requirements

Because PTFE-lined bearings self-lubricate, they eliminate the need for a regular greasing schedule.

This is a critical advantage for components in hard-to-reach locations or in sealed, "fit-for-life" products where maintenance is impossible.

Cleaner Operation

The absence of wet lubricants like grease means PTFE bearings do not attract and hold dirt, dust, or other environmental contaminants.

This makes them the superior choice for cleanroom environments, food processing machinery, and medical devices where contamination control is paramount.

Smoother, Quieter Performance

The consistent, low-friction surface minimizes the "stick-slip" phenomenon common in other materials, resulting in smoother and quieter mechanical motion.

This leads to more precise operation and a reduction in operational noise and vibration.

Tighter Tolerances

High-quality PTFE liners can reduce the required internal clearance between the moving parts of a bearing.

This allows for tighter fits and more precise designs, which is crucial for applications demanding high accuracy and minimal "play" in the system.

Understanding the Trade-offs

While PTFE offers significant advantages, it is not a universal solution. An objective assessment requires acknowledging its limitations compared to traditional metal bearings.

Lower Load Capacity

As a polymer, PTFE inherently has a lower compressive strength and load-bearing capacity than hardened steel.

For applications involving extremely high shock loads or immense static pressure, a traditional rolling-element metal bearing is often necessary.

Susceptibility to Creep

Under a constant, sustained load, plastic materials can slowly deform over time—a phenomenon known as "creep."

Designers must account for this behavior in applications where dimensional stability under long-term stress is critical.

Higher Thermal Expansion

Plastics expand and contract with temperature changes more than metals do.

This higher coefficient of thermal expansion must be factored into the design, especially when tight tolerances are required across a wide operating temperature range.

Making the Right Choice for Your Application

Selecting the correct bearing material depends entirely on the specific goals and constraints of your project.

- If your primary focus is maintenance-free operation: PTFE bearings are ideal for inaccessible locations or for products where regular lubrication is impractical or undesirable.

- If your primary focus is a clean environment: The dry, self-lubricating nature of PTFE is superior for food, medical, or textile applications where contamination from grease is a major concern.

- If your primary focus is extreme load capacity: A traditional, lubricated steel rolling-element bearing will almost always be the more appropriate and reliable choice.

Ultimately, understanding these core principles allows you to select a bearing material based on the specific performance needs of your design, not just on convention.

Summary Table:

| Property | Benefit for Bearings |

|---|---|

| Low Coefficient of Friction | Self-lubricating, eliminates need for grease/oil |

| High Chemical Resistance | Performs in corrosive environments |

| Wide Temperature Range | Stable from cryogenic to high-heat conditions |

| Clean Operation | Ideal for food, medical, and cleanroom applications |

| Quieter Performance | Reduces stick-slip, noise, and vibration |

Ready to integrate high-performance PTFE bearings into your design?

KINTEK specializes in the precision manufacturing of custom PTFE components, including seals, liners, and labware. Whether you need prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, our expertise ensures you get components that deliver reliable, maintenance-free operation.

Contact our experts today to discuss how our PTFE solutions can enhance your application's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments