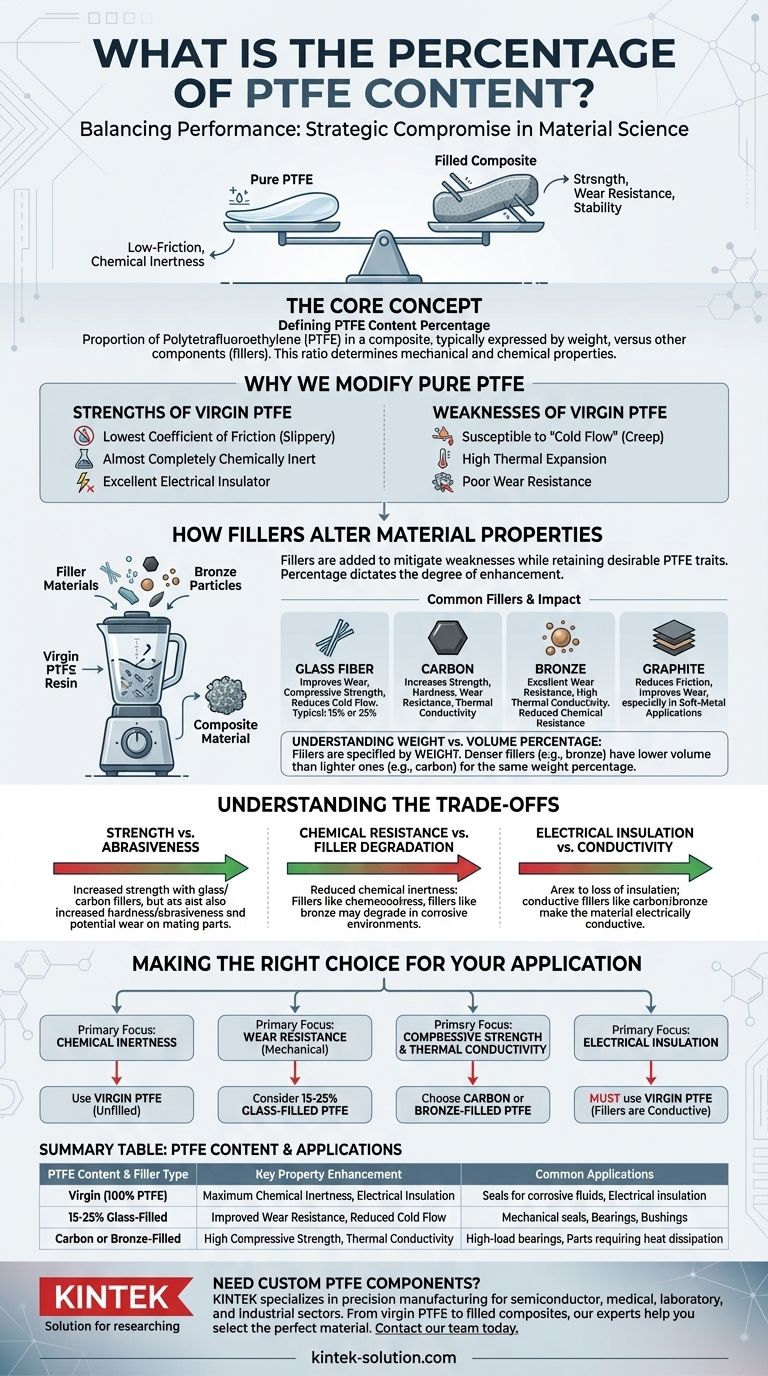

In material science, the percentage of PTFE content refers to the proportion of Polytetrafluoroethylene within a composite material, measured against other components known as fillers. This ratio, typically expressed by weight, is the single most important factor in determining the final mechanical and chemical properties of the material.

The core concept is one of strategic compromise: You are balancing the exceptional low-friction and chemical inertness of pure PTFE against the enhanced strength, wear resistance, and dimensional stability provided by adding specific filler materials.

Why We Modify Pure PTFE

Understanding the purpose of adding fillers begins with understanding the inherent strengths and weaknesses of PTFE in its pure, or "virgin," state.

Strengths of Virgin PTFE

Virgin PTFE is renowned for its unique combination of properties. It has one of the lowest coefficients of friction of any solid material, making it incredibly slippery.

It is also almost completely chemically inert, resisting nearly all industrial chemicals and solvents. Furthermore, it is an excellent electrical insulator.

Weaknesses of Virgin PTFE

Despite these strengths, virgin PTFE is a relatively soft material. It is susceptible to "cold flow" or creep, meaning it can deform permanently under sustained pressure, especially at elevated temperatures.

It also exhibits relatively high thermal expansion and poor wear resistance when subjected to friction, limiting its use in demanding mechanical applications.

How Fillers Alter Material Properties

Adding fillers is a deliberate engineering choice designed to mitigate the weaknesses of virgin PTFE while retaining as much of its desirable characteristics as possible.

The Role of Fillers

Fillers are materials like glass fiber, carbon, bronze, or graphite that are blended with PTFE resin before it is molded. Each filler imparts a different set of properties to the final composite.

The percentage of this filler—for example, "15% glass-filled PTFE"—directly dictates the degree of enhancement.

Common Fillers and Their Impact

- Glass Fiber: The most common filler. It significantly improves wear resistance and compressive strength, reducing cold flow. A typical content is 15% or 25%.

- Carbon: Increases compressive strength, hardness, and wear resistance. It also improves thermal conductivity, helping to dissipate heat in high-speed applications.

- Bronze: Provides excellent wear resistance and high thermal conductivity. Bronze-filled PTFE has higher compressive strength but reduced chemical resistance compared to other grades.

- Graphite: Often used in combination with other fillers like carbon. It reduces the coefficient of friction and improves wear properties, particularly in soft-metal applications.

Understanding Weight vs. Volume Percentage

It's important to note that filler percentages are almost always specified by weight. Because fillers like bronze are much denser than PTFE, a 40% bronze-filled material by weight will have a much lower volume of bronze filler than a 40% carbon-filled material.

Understanding the Trade-offs

Enhancing one property by adding a filler almost always comes at the expense of another. There is no single "best" PTFE composite; there is only the best one for a specific application.

The Cost of Improved Strength

While adding glass or carbon drastically reduces creep and improves wear resistance, it also increases the material's hardness and abrasiveness. A glass-filled PTFE seal, for instance, may cause more wear on a softer metal shaft than virgin PTFE would.

Impact on Chemical Resistance

Fillers like bronze are not as chemically inert as PTFE itself. Using a bronze-filled component in a corrosive environment can lead to filler degradation, compromising the material's integrity. Virgin PTFE remains the superior choice for extreme chemical exposure.

Sacrificing Electrical Insulation

PTFE is an outstanding electrical insulator. However, adding conductive fillers like carbon or bronze completely changes this property, making the material electrically conductive. This can be desirable for static dissipation but is unacceptable for insulation applications.

Making the Right Choice for Your Application

Selecting the correct PTFE content is a matter of prioritizing your application's most critical performance requirement.

- If your primary focus is chemical inertness: Use virgin (unfilled) PTFE, as any filler will compromise its resistance.

- If your primary focus is wear resistance in mechanical parts: Consider 15% or 25% glass-filled PTFE for a strong balance of properties.

- If your primary focus is compressive strength and thermal conductivity: Carbon-filled or bronze-filled PTFE are excellent choices for high-load, high-speed bearings.

- If your primary focus is electrical insulation: You must use virgin PTFE, as most common fillers are conductive.

Ultimately, the percentage of PTFE content is the lever you pull to fine-tune a material for its intended purpose.

Summary Table:

| PTFE Content & Filler Type | Key Property Enhancement | Common Applications |

|---|---|---|

| Virgin (100% PTFE) | Maximum Chemical Inertness, Electrical Insulation | Seals for corrosive fluids, electrical insulation |

| 15-25% Glass-Filled | Improved Wear Resistance, Reduced Cold Flow | Mechanical seals, bearings, bushings |

| Carbon or Bronze-Filled | High Compressive Strength, Thermal Conductivity | High-load bearings, parts requiring heat dissipation |

Need a custom PTFE component engineered for your specific requirements?

At KINTEK, we specialize in precision manufacturing of PTFE components—from seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need the ultimate chemical resistance of virgin PTFE or the enhanced strength of a filled composite, our experts will help you select the perfect material and deliver from prototypes to high-volume orders.

Contact our team today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss

- What industrial applications does PTFE have? Unlock Performance in Extreme Environments

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications

- What are some exceptional properties of PTFE? Unlock Unmatched Performance in Extreme Environments