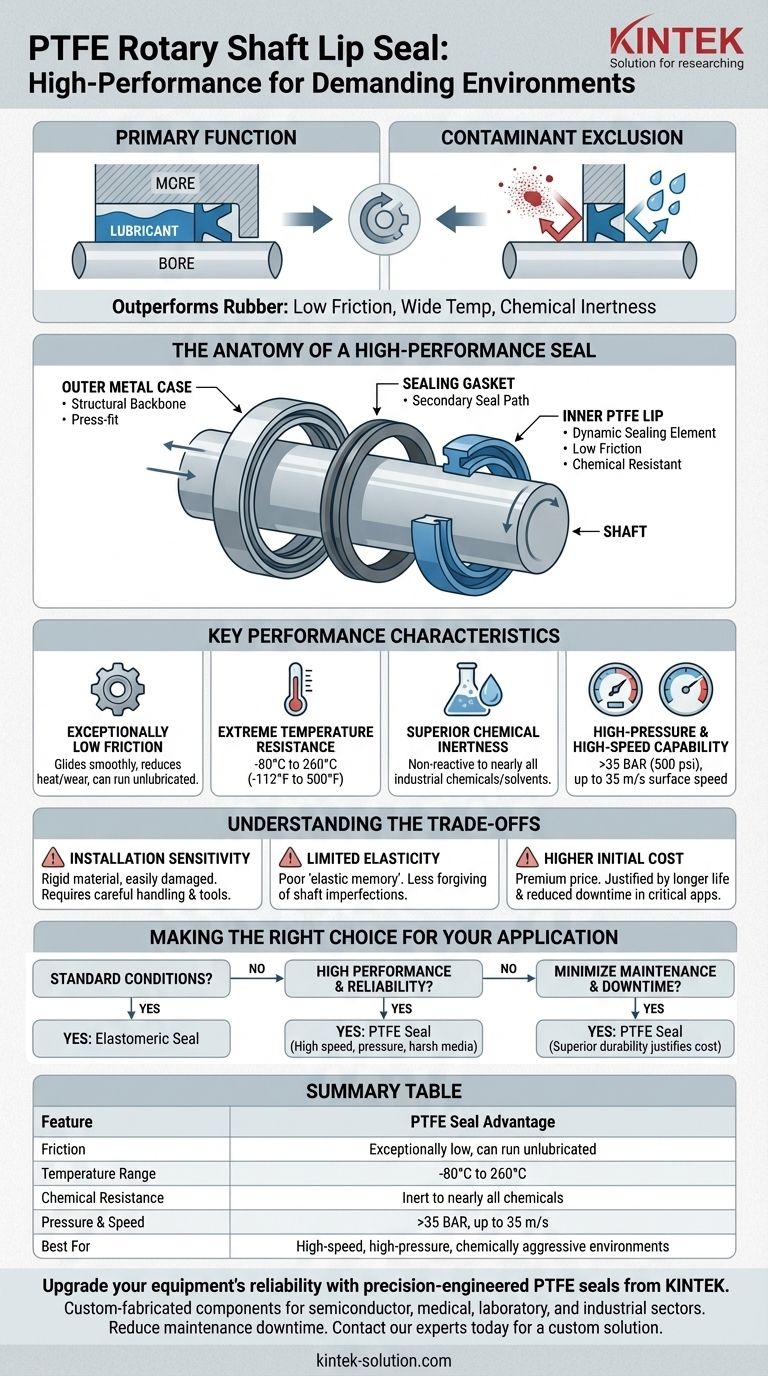

At its core, a PTFE rotary shaft lip seal is a high-performance sealing device designed for demanding environments. Its primary function is twofold: to retain lubricants or system fluids while simultaneously preventing external contaminants like dust and moisture from entering. It creates this dynamic seal between a stationary housing (the bore) and a rotating shaft.

The critical advantage of a PTFE rotary shaft lip seal lies in the material itself. Its exceptionally low friction, wide temperature tolerance, and chemical inertness allow it to outperform traditional rubber seals in high-speed, high-pressure, and chemically aggressive applications.

The Anatomy of a High-Performance Seal

Understanding the construction of a PTFE seal reveals how it achieves its superior performance in challenging conditions. It is an assembly of precision components, each with a specific role.

The Outer Metal Case

The seal's structural backbone is a metal case or "can." This component is designed to be press-fit into the machine's housing or bore.

This provides a rigid and stationary foundation, ensuring the seal remains securely in place during operation.

The Inner PTFE Lip

The PTFE (polytetrafluoroethylene) lip is the dynamic sealing element. This is the part of the seal that is in direct contact with the rotating shaft.

Its unique material properties are the primary reason for the seal's high-performance capabilities.

The Sealing Gasket

In some designs, a gasket is positioned between the PTFE layers and the metal case. This element serves to seal off any potential secondary leak paths through the body of the seal itself.

Key Performance Characteristics

The decision to use a PTFE seal is almost always driven by the operational demands that exceed the capabilities of conventional elastomeric seals.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This allows the seal lip to glide smoothly over the shaft, reducing heat generation and wear.

This property is so effective that many PTFE seals can function perfectly even without lubrication.

Extreme Temperature Resistance

PTFE seals operate reliably across an exceptionally wide temperature range. They maintain their integrity from cryogenic lows of -80°C (-112°F) up to high temperatures of 260°C (500°F).

Superior Chemical Inertness

PTFE is non-reactive to nearly all industrial chemicals, solvents, and lubricants. This chemical resistance prevents the seal from degrading or swelling when exposed to aggressive media.

High-Pressure and High-Speed Capability

Compared to standard seals, PTFE excels under pressure and at high velocities. They are engineered to withstand pressures exceeding 35 BAR (500 psi) and surface speeds up to 35 m/s.

Understanding the Trade-offs

While highly effective, PTFE seals are not a universal solution. Their distinct material properties introduce specific considerations that are critical for success.

Installation Sensitivity

PTFE is a relatively rigid material compared to rubber. The sealing lip can be easily nicked or damaged during installation, which can cause an immediate leak.

Careful handling and proper installation tools are not just recommended; they are essential for a reliable seal.

Limited Elasticity

Unlike rubber, PTFE has poor "elastic memory," meaning it does not spring back into shape as readily after being deformed.

This makes it less forgiving of shaft imperfections, such as scratches or significant runout, which can compromise the sealing interface.

Higher Initial Cost

High-performance materials come at a premium. PTFE seals typically have a higher upfront cost than their standard nitrile or Viton counterparts.

The investment is justified by longer service life and reduced equipment downtime in applications where other seals would fail prematurely.

Making the Right Choice for Your Application

Selecting the correct seal requires matching the material's capabilities to the operational demands of your equipment.

- If your primary focus is standard operating conditions: A traditional elastomeric seal is likely more cost-effective where extreme temperatures, high speeds, or aggressive chemicals are not factors.

- If your primary focus is high performance and reliability: A PTFE seal is the definitive choice for applications involving high surface speeds, significant pressures, or exposure to harsh media.

- If your primary focus is minimizing maintenance and downtime: The superior durability of PTFE seals often justifies their initial cost by drastically reducing the frequency of replacement in critical machinery.

By understanding its unique material advantages, you can leverage the PTFE rotary shaft seal to achieve superior reliability in your most demanding applications.

Summary Table:

| Feature | PTFE Seal Advantage |

|---|---|

| Friction | Exceptionally low, can run unlubricated |

| Temperature Range | -80°C to 260°C (-112°F to 500°F) |

| Chemical Resistance | Inert to nearly all industrial chemicals |

| Pressure & Speed | >35 BAR (500 psi), up to 35 m/s surface speed |

| Best For | High-speed, high-pressure, chemically aggressive environments |

Upgrade your equipment's reliability with precision-engineered PTFE seals from KINTEK.

If your operations in the semiconductor, medical, laboratory, or industrial sectors demand seals that can withstand extreme temperatures, high speeds, aggressive chemicals, and significant pressure, our custom-fabricated PTFE components are the solution. We specialize in manufacturing high-performance PTFE seals, liners, and labware, offering everything from prototypes to high-volume orders with a focus on precision and durability.

Reduce maintenance downtime and extend the life of your critical machinery. Contact our experts today to discuss your specific application requirements and receive a custom solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs