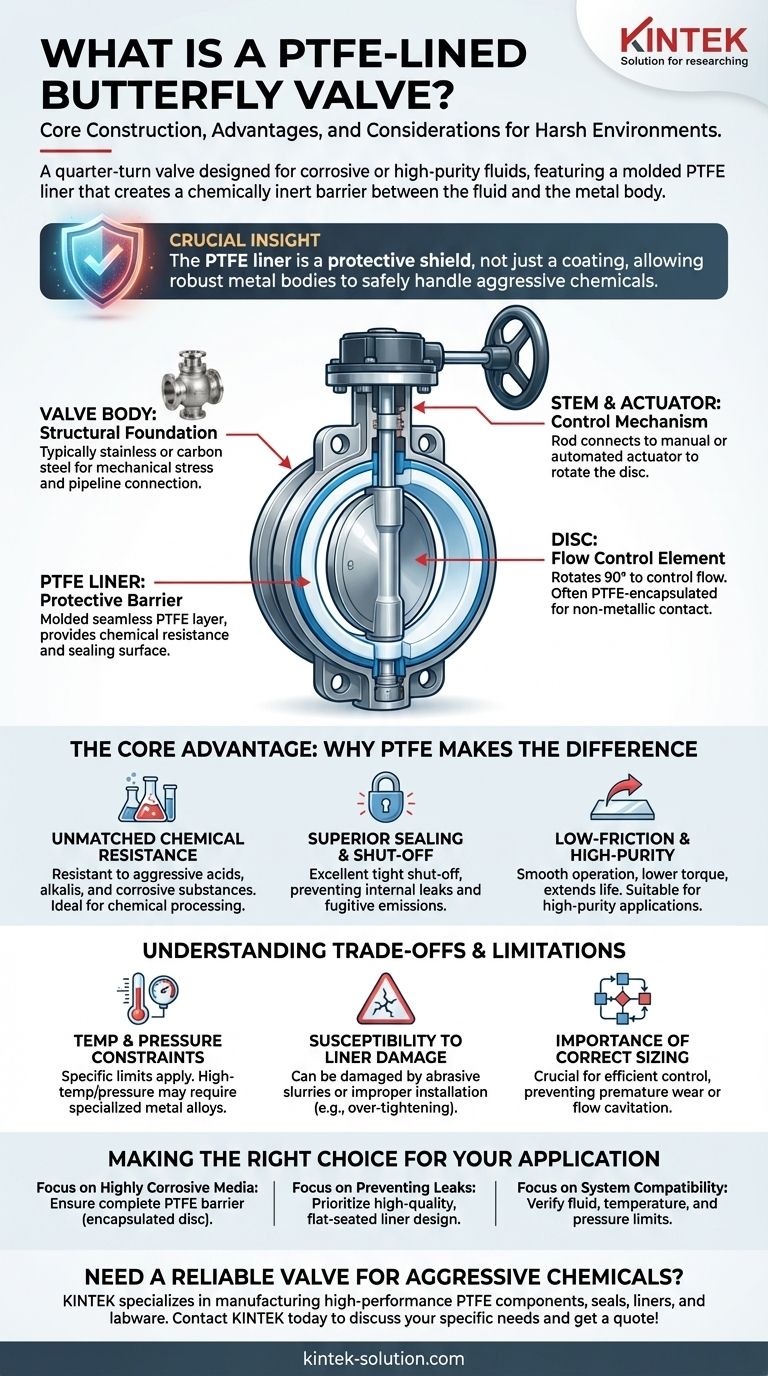

At its core, a PTFE-lined butterfly valve is a quarter-turn valve engineered to control or stop the flow of highly corrosive or high-purity fluids. Its defining feature is a liner made of Polytetrafluoroethylene (PTFE) that coats the valve's interior, creating a chemically inert barrier between the fluid and the valve's metal body. This design combines the simple, fast-acting operation of a butterfly valve with the exceptional chemical resistance of PTFE.

The crucial insight is that the PTFE liner is not just a coating; it is a fundamental design component that acts as a protective shield. This allows a robust, cost-effective valve body (like carbon or stainless steel) to safely manage aggressive chemicals that would otherwise require exotic and expensive metal alloys.

How a PTFE-Lined Butterfly Valve is Constructed

A PTFE-lined butterfly valve operates on a simple principle but relies on a precise combination of components to achieve its reliability in harsh environments.

The Valve Body: The Structural Foundation

The outer body provides the structural integrity and connection points for the pipeline. It is typically manufactured from durable metals like stainless steel or carbon steel.

This robust exterior handles the mechanical stress and pressure of the system, while the internal lining handles the chemical stress.

The PTFE Liner: The Protective Barrier

This is the most critical component. A thick layer of PTFE is molded to the interior of the valve body, creating a seamless, non-reactive surface.

This liner serves two primary purposes: it provides a protective barrier against corrosion and creates the valve's sealing surface, ensuring a tight shut-off when closed. The smooth, low-friction nature of PTFE also facilitates smooth operation.

The Disc: The Flow Control Element

A circular disc is positioned in the center of the valve. By rotating the disc ninety degrees, it moves from a position parallel to the flow (fully open) to perpendicular to the flow (fully closed).

In many designs, the disc itself is also encapsulated or lined with PTFE, ensuring that no metallic parts come into contact with the process fluid.

The Stem and Actuator: The Control Mechanism

A rod, known as the stem, passes through the disc and connects to an actuator on the outside of the valve.

This actuator, which can be a manual handle, lever, or an automated pneumatic or electric system, is used to rotate the stem and, consequently, the disc to control the flow.

The Core Advantage: Why PTFE Makes the Difference

The choice to use a PTFE lining is deliberate and provides distinct operational benefits over standard butterfly valves.

Unmatched Chemical Resistance

PTFE is famously inert and resistant to a vast range of chemicals, including aggressive acids, alkalis, and other corrosive substances. This makes it ideal for chemical processing and pharmaceutical applications.

Superior Sealing and Shut-Off

The design provides excellent tight shut-off capabilities. The PTFE liner creates a resilient, flat-seated seal with the disc, preventing internal leaks within the piping system and eliminating fugitive emissions into the atmosphere.

Low-Friction and High-Purity

The low-friction surface of PTFE ensures smooth, lower-torque operation, which can extend the life of the valve and its actuator. Its inert nature also makes it suitable for high-purity applications where media contamination is a concern.

Understanding the Trade-offs and Limitations

While highly effective, these valves are not a universal solution. Understanding their operational limits is critical for proper application.

Temperature and Pressure Constraints

PTFE has specific temperature and pressure limits. While it performs well in many scenarios, applications involving very high temperatures or pressures may require valves made from specialized metal alloys that can maintain their structural integrity under more extreme conditions.

Susceptibility to Liner Damage

The PTFE liner, while durable, can be damaged by highly abrasive slurries or improper installation (e.g., over-tightening flanges). Any breach in the liner exposes the metal body to the corrosive media, defeating the valve's primary purpose.

The Importance of Correct Sizing

Proper valve sizing is crucial. It must be based on the required flow rate, pressure drop, and pipe diameter to ensure efficient control and prevent premature wear or operational issues like flow cavitation.

Making the Right Choice for Your Application

Selecting the correct valve requires a clear understanding of your system's demands.

- If your primary focus is handling highly corrosive media: The key is ensuring the PTFE barrier is complete, often by selecting a valve where both the liner and disc are fully encapsulated.

- If your primary focus is preventing all leaks: Prioritize valves with a high-quality, flat-seated liner design that guarantees tight shut-off performance.

- If your primary focus is system compatibility: You must verify that your specific fluid, operating temperature, and pressure are all within the stated limits for the valve.

Ultimately, choosing a PTFE-lined butterfly valve is a strategic decision to gain elite chemical resistance without the high cost of exotic alloy valves.

Summary Table:

| Component | Material & Function |

|---|---|

| Valve Body | Carbon or stainless steel for structural integrity and pipeline connection. |

| PTFE Liner | Molded PTFE layer providing a chemically inert barrier and sealing surface. |

| Disc | Flow control element, often PTFE-encapsulated to prevent fluid contact with metal. |

| Stem & Actuator | Mechanism (manual or automated) to rotate the disc for quarter-turn operation. |

Need a reliable valve for aggressive chemicals?

KINTEK specializes in manufacturing high-performance PTFE components, including custom-fabricated seals, liners, and labware. Our expertise in precision PTFE fabrication ensures your valves and systems meet the demanding requirements of the semiconductor, medical, laboratory, and industrial sectors.

We deliver solutions from prototypes to high-volume orders, guaranteeing the chemical resistance and purity your application demands.

Contact KINTEK today to discuss your specific needs and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications