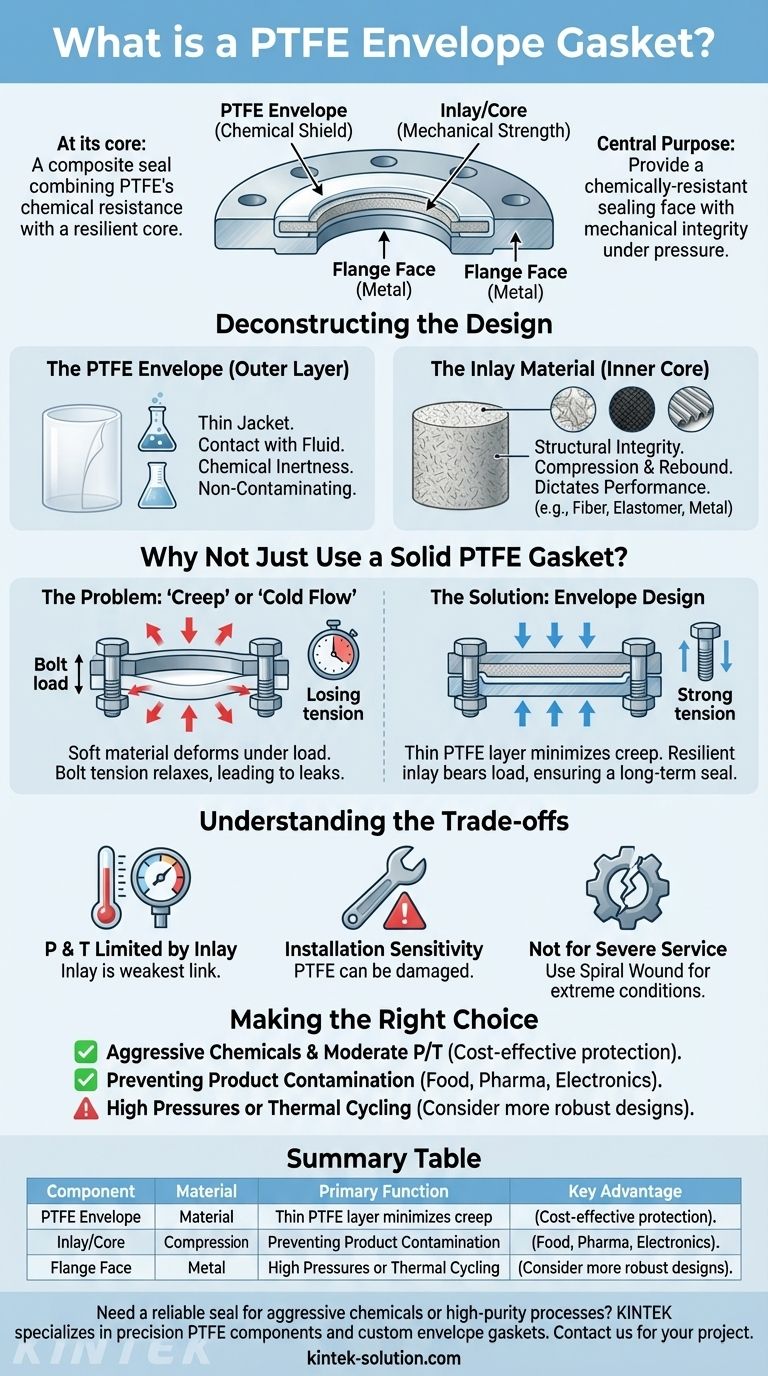

At its core, a PTFE envelope gasket is a composite seal designed to combine the superior chemical resistance of Polytetrafluoroethylene (PTFE) with the mechanical strength and resilience of a different core material. It consists of a softer, more robust inlay material that is completely enclosed within a thin "envelope" of PTFE, creating a gasket that offers the best of both worlds.

The central purpose of a PTFE envelope gasket is to provide an exceptionally chemical-resistant sealing face for a flange, while using a separate internal material to provide the mechanical integrity needed to maintain that seal under pressure.

Deconstructing the PTFE Envelope Gasket

To understand its function, you must look at the two distinct components that work in tandem. The design leverages the unique properties of each material to overcome their individual limitations.

The PTFE Envelope (The Chemical Shield)

The outer layer is a thin jacket of pure PTFE. This envelope is the only part of the gasket that comes into contact with the process fluid.

The key benefit of this PTFE layer is its near-universal chemical inertness. It is resistant to almost all acids, bases, and solvents, making it ideal for aggressive chemical processing. It also provides a non-contaminating surface suitable for food, beverage, and pharmaceutical applications.

The Inlay Material (The Mechanical Core)

Inside the envelope sits the inlay, which provides the gasket's structural integrity. This core material gives the gasket its ability to be compressed and to rebound, maintaining a tight seal even as conditions fluctuate.

The choice of inlay is critical and dictates the gasket's overall performance. Common materials include compressed non-asbestos fiber for general use, various elastomers (rubber) for better sealing on irregular flanges, or corrugated metal for higher pressure and temperature applications.

Why Not Just Use a Solid PTFE Gasket?

While solid PTFE gaskets exist, they have a significant engineering drawback that the envelope design solves directly.

The Problem of "Creep"

PTFE is a relatively soft material. When placed under the high compressive load of flange bolts, it is prone to "creep" or "cold flow." This means the material slowly deforms and flows outward from the pressure point.

This creep causes the bolt tension to relax over time, which can lead to a loss of sealing pressure and eventual leakage.

The Envelope Solution

The envelope gasket design brilliantly solves this problem. By using only a thin layer of PTFE, it minimizes the amount of material that can creep.

The internal inlay, which is specifically chosen for its mechanical strength and resistance to compression, bears the brunt of the bolt load. This provides a stable, resilient core that prevents creep and ensures a reliable, long-term seal.

Understanding the Trade-offs

While highly effective, this design is not a universal solution. Understanding its limitations is key to proper application.

Temperature and Pressure are Limited by the Inlay

The gasket's maximum operating temperature and pressure are determined by its weakest component. While PTFE can handle high temperatures, a rubber or fiber inlay will have a much lower limit, making the inlay the determining factor for the gasket's overall rating.

Installation Sensitivity

The thin PTFE envelope can be damaged if not handled and installed with care. Overtightening the flange bolts can crush the inlay and split the envelope, completely negating its chemical resistance and causing immediate failure.

Not Ideal for Severe Service

For applications involving extreme pressures, high temperatures, or significant thermal cycling, other gasket designs like spiral wound or kammprofile gaskets are often a more robust choice. The differential thermal expansion between the PTFE and the inlay can become a problem in these severe services.

Making the Right Choice for Your Application

Use this as a guide to determine if a PTFE envelope gasket fits your specific goal.

- If your primary focus is sealing aggressive chemicals at moderate pressures and temperatures: A PTFE envelope gasket is an excellent and cost-effective choice, providing elite chemical protection.

- If your primary focus is preventing product contamination (food, pharma, electronics): The inert PTFE sealing face is ideal for maintaining purity, while the inlay ensures a reliable seal.

- If your primary focus is handling high pressures or significant thermal cycling: You should carefully evaluate the gasket's specifications and consider a more mechanically robust design, such as a spiral wound gasket.

This composite design provides a specialized solution, delivering outstanding chemical inertness and reliable mechanical performance for a wide range of critical industrial applications.

Summary Table:

| Component | Material | Primary Function |

|---|---|---|

| Envelope | PTFE (Polytetrafluoroethylene) | Provides a chemically inert, non-contaminating sealing face. |

| Inlay/Core | Compressed Fiber, Elastomer, or Metal | Provides mechanical strength, compression, and resilience to prevent creep. |

| Key Advantage | --- | Solves the "creep" problem of solid PTFE gaskets for a reliable, long-term seal. |

Need a reliable seal for aggressive chemicals or high-purity processes?

KINTEK specializes in manufacturing precision PTFE components, including custom envelope gaskets. We combine expert material selection with high-quality fabrication to deliver seals that meet the exact demands of your application in the semiconductor, medical, laboratory, and industrial sectors.

Contact KINTEK today to discuss your project—from prototype to high-volume production—and ensure a leak-free operation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- When and by whom was PTFE discovered? A Tale of Accidental Innovation