In short, a PTFE coating thrust washer is a standard thrust washer that has been coated with a layer of Polytetrafluoroethylene (PTFE). This specialized coating is applied to dramatically reduce friction and increase the component's resistance to wear, chemicals, and heat, transforming it into a high-performance, self-lubricating part.

The central purpose of adding a PTFE coating to a thrust washer is to create an exceptionally smooth, durable, and self-lubricating surface. This allows for efficient management of axial loads with minimal friction, which is critical for the longevity and performance of rotating assemblies.

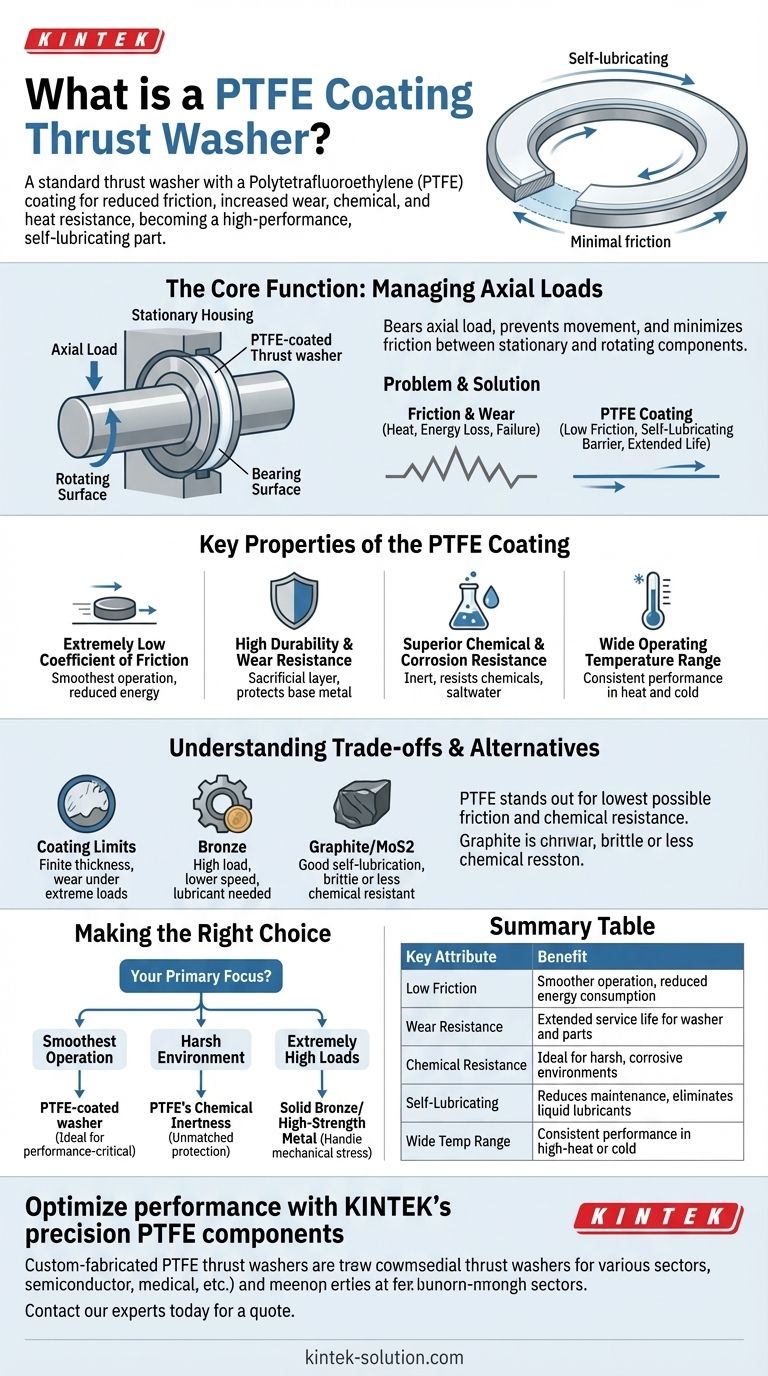

The Core Function: Managing Axial Loads

A thrust washer's job is to bear an "axial" or "thrust" load. It serves as a bearing surface between a stationary component and a rotating surface, such as a shaft or gear, to prevent movement along the axis of rotation.

The Problem of Friction and Wear

In any rotating assembly, the friction between the washer and the moving component generates heat, causes wear, and wastes energy. Over time, this can lead to component failure and degraded performance.

The Role of the PTFE Coating

Applying a thin layer of PTFE directly addresses this problem. The coating acts as a solid, dry lubricant bonded to the washer's surface, creating a barrier that minimizes direct metal-to-metal contact.

Key Properties of the PTFE Coating

The effectiveness of a PTFE coating stems from the unique properties of the polymer itself. These characteristics make it suitable for a wide range of demanding applications.

Extremely Low Coefficient of Friction

PTFE is famous for having one of the lowest coefficients of friction of any solid material. This results in exceptionally smooth, efficient operation, reducing the energy required to overcome rotational resistance.

High Durability and Wear Resistance

The coating acts as a protective, sacrificial layer. It absorbs the wear that would otherwise damage the base metal of the washer or the mating component, significantly extending the service life of the entire assembly.

Superior Chemical and Corrosion Resistance

PTFE is chemically inert, meaning it does not react with most chemicals, solvents, or oils. This makes PTFE-coated washers ideal for use in corrosive environments, such as saltwater or chemical processing equipment.

Wide Operating Temperature Range

PTFE maintains its key properties across a broad spectrum of temperatures. It can withstand high heat without degrading and remains effective in cold conditions, providing consistent performance.

Understanding the Trade-offs and Alternatives

While highly versatile, PTFE-coated washers are not the universal solution for every application. Understanding their limitations is key to proper selection.

The Limits of a Coating

A PTFE coating has a finite thickness. In applications with extremely high shock loads or intense abrasive conditions, the coating can eventually wear away, diminishing its effectiveness. The overall load capacity is still largely determined by the base metal of the washer.

Comparing Common Alternatives

Other materials are often used for thrust washers, each with its own strengths:

- Bronze: Offers excellent load-carrying capacity and is often embedded with lubricants like graphite. It is a good choice for high-load, lower-speed applications.

- Graphite: Provides good self-lubricating properties, but can be more brittle than a coated metal washer.

- Molybdenum Disulfide (MoS2): Another dry lubricant coating that excels in high-pressure environments, but may not offer the same level of chemical resistance as PTFE.

PTFE stands out as the premium choice for applications where the lowest possible friction and corrosion resistance are the primary goals.

Making the Right Choice for Your Application

Selecting the correct thrust washer requires matching the component's properties to the specific demands of your assembly.

- If your primary focus is smoothest possible operation: The exceptionally low friction of a PTFE-coated washer is the ideal choice for performance-critical applications.

- If your primary focus is operation in a harsh environment: PTFE’s superior chemical inertness provides unmatched protection against corrosion from chemicals or saltwater.

- If your primary focus is managing extremely high loads: A solid bronze or other high-strength metal alloy washer may be required to handle the mechanical stress.

Ultimately, choosing the right thrust washer is a critical engineering decision that directly impacts the efficiency, reliability, and lifespan of your equipment.

Summary Table:

| Key Attribute | Benefit |

|---|---|

| Low Friction | Smoother operation, reduced energy consumption |

| Wear Resistance | Extended service life for the washer and mating parts |

| Chemical Resistance | Ideal for harsh, corrosive environments |

| Self-Lubricating | Reduces maintenance needs and eliminates liquid lubricants |

| Wide Temp Range | Consistent performance in high-heat or cold conditions |

Optimize your equipment's performance and longevity with precision-engineered PTFE components from KINTEK.

Whether your application is in the semiconductor, medical, laboratory, or industrial sector, our custom-fabricated PTFE thrust washers, seals, liners, and labware are designed to meet the most demanding requirements. We specialize in creating solutions that offer superior friction reduction, chemical resistance, and durability.

From initial prototypes to high-volume production, our team ensures every component meets your exact specifications. Let's discuss how we can enhance your assembly – contact our experts today for a quote or to discuss your project needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech