At their core, PTFE V-Rings are specified for industries that cannot afford seal failure, including chemical processing, food and beverage, pharmaceuticals, and automotive. Their adoption is driven by PTFE’s unique ability to withstand aggressive chemicals, extreme temperatures, and dynamic friction where lesser materials would quickly degrade.

The question isn't just which industries use PTFE V-Rings, but why they have become the default choice for critical sealing applications. The answer lies in PTFE's unmatched combination of chemical inertness, temperature resilience, and low friction.

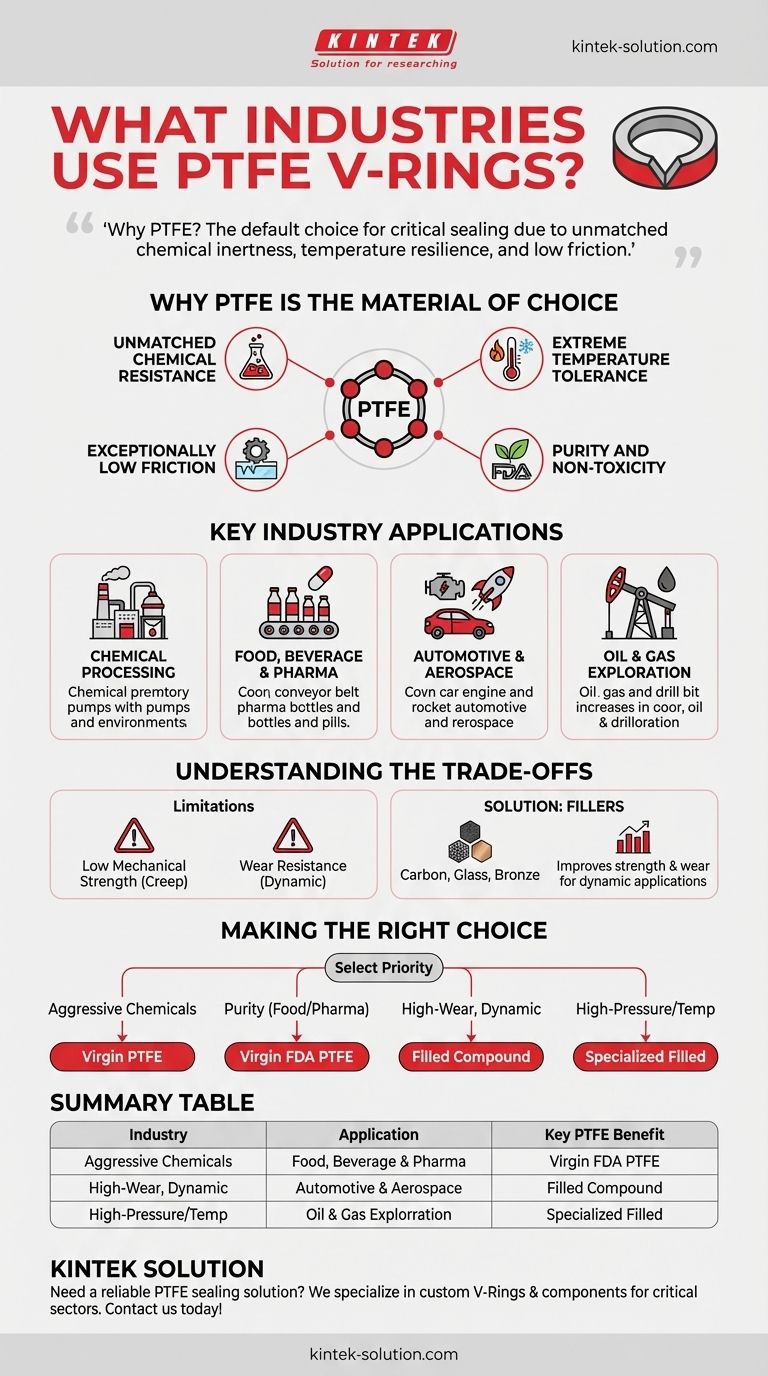

Why PTFE is the Material of Choice for Demanding Seals

The value of a PTFE V-Ring is not in the component itself, but in the properties of the material it is made from. Understanding these properties is key to understanding its industrial applications.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals, acids, and solvents. This makes it an essential material for equipment that handles corrosive substances.

Seals made from other materials would corrode and fail, leading to dangerous leaks and costly downtime.

Extreme Temperature Tolerance

PTFE maintains its integrity and sealing capability across an exceptionally wide temperature range. It can perform reliably in cryogenic conditions and in high-heat environments where many plastics and elastomers would become brittle or melt.

This thermal stability is critical for processes in aerospace, automotive engines, and industrial manufacturing.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "non-stick" property is vital for dynamic seals in moving parts like pumps and pistons.

This reduces wear on machinery, lowers energy consumption, and prevents the "stick-slip" phenomenon that can cause jerky movement and premature failure.

Purity and Non-Toxicity

Virgin PTFE is inherently pure, non-toxic, and can comply with strict regulatory standards, including those from the FDA. It does not impart taste, color, or contaminants.

This makes it the only viable choice for many applications in food processing, beverage production, and pharmaceutical manufacturing where product purity is non-negotiable.

Key Industry Applications in Detail

These fundamental properties directly translate into mission-critical applications across several major sectors.

Chemical Processing and Manufacturing

In this industry, V-rings are used to seal pumps, valves, and mixers that handle highly corrosive substances. The chemical inertness of PTFE prevents seal degradation and ensures process safety.

Food, Beverage, and Pharmaceuticals

Here, hygiene is paramount. PTFE V-rings are used in processing and packaging equipment because they are non-toxic, do not contaminate the product, and can withstand aggressive clean-in-place (CIP) chemicals and high-temperature sterilization.

Automotive and Aerospace

In automotive engines and transmissions, PTFE V-rings seal fluids under high-temperature and high-wear conditions. In aerospace, they are used in hydraulic systems and fuel lines where reliability across extreme temperature shifts is essential.

Oil and Gas Exploration

PTFE seals are critical in high-pressure, high-temperature (HPHT) downhole tools and surface equipment. They must resist aggressive chemicals and maintain a seal under immense mechanical stress, preventing catastrophic failures.

Understanding the Trade-offs

No material is perfect, and being an effective advisor means acknowledging limitations. Objectivity requires understanding where PTFE might not be the right choice without modification.

Low Mechanical Strength

Unfilled, or "virgin," PTFE is a relatively soft material. Under high mechanical loads, it can be prone to deformation, a phenomenon known as creep or cold flow.

Wear Resistance

While its low friction reduces wear, pure PTFE itself can wear down in high-speed, dynamic applications without reinforcement.

The Role of Fillers

To counteract these weaknesses, PTFE is often blended with fillers like carbon, glass fiber, or bronze. These fillers dramatically improve mechanical strength, wear resistance, and dimensional stability, making the V-rings suitable for much more demanding dynamic and high-pressure applications.

Making the Right Choice for Your Application

The selection of a PTFE V-ring is not a one-size-fits-all decision. It must be aligned with the specific demands of the operating environment.

- If your primary focus is sealing against aggressive chemicals: Virgin PTFE is often the best choice due to its superior chemical inertness.

- If your primary focus is ensuring purity in food or pharma: You must specify virgin, FDA-compliant PTFE to avoid any possibility of contamination.

- If your primary focus is a high-wear, dynamic application: A filled PTFE compound (e.g., carbon or glass-filled) is necessary to provide the required mechanical strength and durability.

- If your primary focus is a high-pressure, high-temperature environment: A specialized, filled PTFE V-ring is required to resist creep and maintain seal integrity under extreme stress.

Understanding the core properties of PTFE allows you to select the precise sealing solution that ensures reliability, safety, and performance.

Summary Table:

| Industry | Primary Application | Key PTFE Benefit |

|---|---|---|

| Chemical Processing | Sealing pumps, valves, and mixers | Unmatched chemical resistance |

| Food, Beverage & Pharma | Processing and packaging equipment | Purity, non-toxicity, FDA compliance |

| Automotive & Aerospace | Engine seals, hydraulic systems | Extreme temperature tolerance |

| Oil & Gas | High-pressure, high-temperature tools | Chemical and thermal stability |

Need a reliable PTFE sealing solution for your critical application? At KINTEK, we specialize in manufacturing high-performance PTFE components—including custom V-Rings, seals, liners, and labware—for semiconductor, medical, laboratory, and industrial sectors. Whether you require virgin PTFE for chemical resistance or filled compounds for dynamic wear, our precision production and custom fabrication (from prototypes to high-volume orders) ensure your seals perform under extreme conditions. Contact us today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs