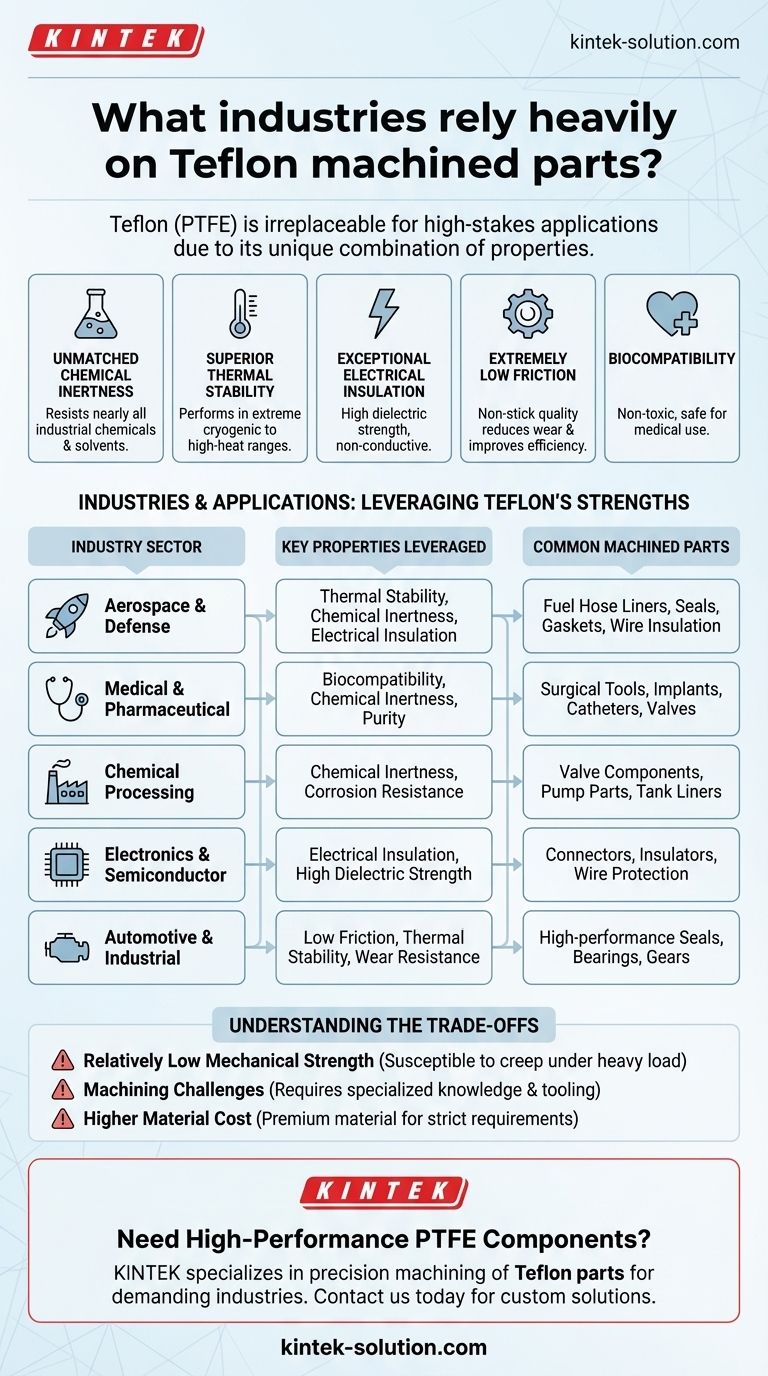

To be direct, the industries that rely most heavily on Teflon (PTFE) machined parts are aerospace, medical, chemical processing, and electronics. These sectors depend on Teflon's unique combination of chemical inertness, thermal stability, and low friction to solve engineering challenges that other materials cannot.

The selection of Teflon is rarely based on a single property. Instead, it is chosen for its powerful combination of attributes, making it an irreplaceable material for high-stakes applications where performance in extreme environments is non-negotiable.

Why These Industries Depend on Teflon (PTFE)

Teflon, the brand name for Polytetrafluoroethylene (PTFE), is a high-performance fluoropolymer. Its molecular structure gives it a set of properties that make it uniquely suited for demanding industrial roles.

Unmatched Chemical Inertness

Teflon is resistant to nearly all industrial chemicals and solvents. This makes it essential in industries where corrosion or contamination would lead to catastrophic failure.

It is the material of choice for seals, liners, and valve components in the chemical processing and pharmaceutical sectors.

Superior Thermal Stability

PTFE maintains its properties across a very wide range of temperatures. It can perform reliably in cryogenic conditions as well as in high-heat environments.

This stability is critical for components in aerospace vehicles and automotive engines, which experience extreme temperature fluctuations.

Exceptional Electrical Insulation

Teflon is an excellent electrical insulator with very high dielectric strength. It does not conduct electricity, making it perfect for protecting sensitive electronics.

This property is leveraged heavily in the electronics, semiconductor, and aerospace industries for wire insulation, connectors, and insulators.

Extremely Low Friction

Teflon has one of the lowest coefficients of friction of any solid material, giving it a "non-stick" quality. This reduces wear and improves mechanical efficiency.

This is why it's used for high-performance bearings, gears, and seals in the automotive and general industrial sectors.

Biocompatibility for Medical Applications

Teflon is non-toxic and does not react with bodily tissues or fluids, making it highly biocompatible.

The medical device industry relies on this for manufacturing implants, surgical instruments, catheters, and prosthetics that are safe for use within the human body.

Common Applications by Industry

Understanding the specific parts made from Teflon illustrates why it is so critical to these sectors.

In Aerospace & Defense

Reliability is paramount. Teflon is used for fuel hoses, seals, and gaskets that must withstand aggressive fuels and extreme temperatures. Its use as wire insulation is also critical for protecting vital electrical systems.

In Medical & Pharmaceutical

Purity is the primary driver. Components for surgical tools, valves for handling pure chemicals, and tubing must remain completely inert to avoid contamination.

In Chemical & Food Processing

Preventing corrosion is the main goal. Valve components, pump parts, and tank liners made from Teflon ensure equipment longevity and prevent contamination of the final product.

In Automotive & Electronics

Performance and protection are key. Teflon is used for high-performance seals and bearings that reduce friction in engines, as well as for insulators protecting mission-critical semiconductor components.

Understanding the Trade-offs

While its properties are exceptional, Teflon is not a universal solution. An expert must understand its limitations to specify it correctly.

Relatively Low Mechanical Strength

Compared to metals or even other high-performance plastics, Teflon is relatively soft. It can be susceptible to "creep" or deformation under a constant heavy load.

Machining Challenges

The material's softness can make it challenging to machine to extremely tight tolerances. This requires specialized knowledge and tooling to prevent deformation during the CNC machining process.

Higher Material Cost

PTFE is a premium material. Its cost is higher than that of common plastics like nylon or Delrin, so its use is typically reserved for applications where its unique properties are a strict requirement.

Making the Right Choice for Your Goal

Selecting Teflon should be a deliberate decision based on the specific problem you are trying to solve.

- If your primary focus is reliability in extreme temperatures or chemical exposure: Teflon is an ideal choice for seals, gaskets, and valve components that cannot fail.

- If your primary focus is electrical insulation: Its high dielectric strength makes it a go-to material for critical insulators in aerospace and electronics.

- If your primary focus is low-friction movement and wear resistance: It excels in applications like bearings and non-stick surfaces where mechanical efficiency is key.

- If your primary focus is biocompatibility and purity: Teflon is a standard in the medical and food processing industries for implants and components that must remain inert.

Understanding these core strengths allows you to strategically leverage Teflon's properties to solve your most demanding engineering challenges.

Summary Table:

| Industry | Key PTFE Properties Leveraged | Common Applications |

|---|---|---|

| Aerospace & Defense | Thermal Stability, Chemical Inertness, Electrical Insulation | Fuel hose liners, seals, gaskets, wire insulation |

| Medical & Pharmaceutical | Biocompatibility, Chemical Inertness, Purity | Surgical tools, implants, catheters, valves |

| Chemical Processing | Chemical Inertness, Corrosion Resistance | Valve components, pump parts, tank liners |

| Electronics & Semiconductor | Electrical Insulation, High Dielectric Strength | Connectors, insulators, wire protection |

| Automotive & Industrial | Low Friction, Thermal Stability, Wear Resistance | High-performance seals, bearings, gears |

Need High-Performance PTFE Components for Your Critical Application?

KINTEK specializes in the precision machining of Teflon (PTFE) parts for the most demanding industries, including semiconductor, medical, laboratory, and industrial sectors. We understand the critical nature of your applications and provide custom fabrication from prototypes to high-volume orders, ensuring the chemical inertness, thermal stability, and reliability your projects demand.

Contact KINTEK today to discuss your specific requirements and let our expertise in PTFE machining provide the solution you need.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications