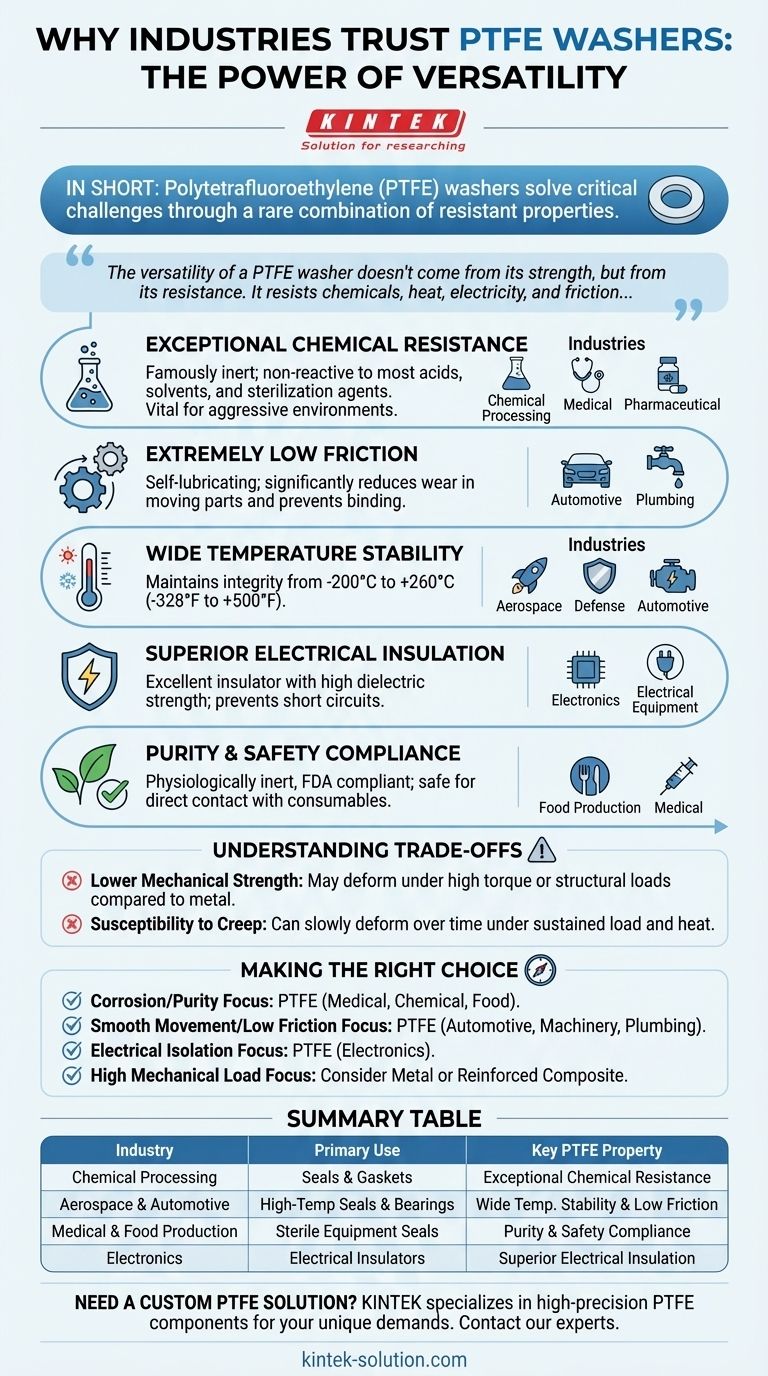

In short, Polytetrafluoroethylene (PTFE) washers are utilized across a vast range of demanding industries. This includes aerospace, automotive, chemical processing, medical and food production, and electronics. Their widespread adoption is not due to a single feature, but a rare combination of properties that solve critical engineering challenges in each of these unique environments.

The versatility of a PTFE washer doesn't come from its strength, but from its resistance. It resists chemicals, heat, electricity, and friction, making it a problem-solver in environments where other materials would quickly fail.

The Core Properties Driving PTFE Adoption

The use of PTFE washers is a lesson in material science. Understanding the specific properties that make it so valuable explains its presence in everything from a spacecraft to a kitchen faucet. Each characteristic meets a distinct industrial need.

### Exceptional Chemical Resistance

PTFE is famously inert, meaning it does not react with most chemicals. This makes it invaluable for creating seals and gaskets in aggressive environments.

This property is non-negotiable in the chemical processing, medical, and pharmaceutical industries, where equipment is constantly exposed to corrosive acids, solvents, or sterilization agents.

### Extremely Low Friction

Often marketed as Teflon®, PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating, non-stick quality is critical for moving parts.

In the automotive sector, it reduces wear in bearings and joints. In plumbing, it ensures taps and valves can be turned smoothly and create a tight seal without binding.

### Wide Temperature Stability

PTFE washers maintain their integrity and performance across an exceptionally broad temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This thermal stability is essential for aerospace and defense applications, where components are exposed to extreme temperature fluctuations. It is also vital in automotive engine compartments and industrial machinery.

### Superior Electrical Insulation

PTFE is an excellent electrical insulator, possessing high dielectric strength. It effectively blocks the flow of electricity.

This makes it a default choice in electronics and electrical equipment for isolating components, preventing short circuits, and ensuring the safety and reliability of sensitive circuits.

### Purity and Safety Compliance

Because PTFE is physiologically inert and can meet stringent regulatory standards (like FDA compliance), it is safe for direct contact with consumable products.

This is the primary reason for its use in the food production and medical industries. It is used in processing machinery, pumps, and medical devices where contamination cannot be tolerated.

Understanding the Trade-offs

While its properties are impressive, PTFE is not a universal solution. An objective assessment requires understanding its limitations.

### Lower Mechanical Strength

Compared to metal washers, PTFE has significantly lower compressive strength and rigidity. It is a relatively soft material.

For applications requiring high torque or extreme structural loads, a standard PTFE washer may deform or fail. In these cases, metal or reinforced polymer washers are superior.

### Susceptibility to Creep

Under a sustained load, especially at elevated temperatures, PTFE can slowly deform over time in a process known as "creep."

Engineers must account for this behavior in long-term, high-pressure sealing applications to prevent eventual leakage or loss of clamping force.

Making the Right Choice for Your Application

Selecting the right washer depends entirely on the primary challenge you need to solve. Your application's environment and performance demands should guide your decision.

- If your primary focus is corrosion or chemical purity: PTFE is an ideal choice, particularly for the medical, chemical, and food processing industries.

- If your primary focus is smooth movement and low friction: PTFE's self-lubricating nature is perfect for automotive parts, industrial machinery, and plumbing fixtures.

- If your primary focus is electrical isolation: PTFE is one of the best and most reliable insulators available for electronic components.

- If your primary focus is high mechanical load and rigidity: You should consider a metal washer or a specially reinforced PTFE composite instead.

Ultimately, choosing a PTFE washer is a decision to prioritize chemical, thermal, and electrical resilience over raw mechanical strength.

Summary Table:

| Industry | Primary Use of PTFE Washers | Key PTFE Property Utilized |

|---|---|---|

| Chemical Processing | Seals & Gaskets | Exceptional Chemical Resistance |

| Aerospace & Automotive | High-Temp Seals & Bearings | Wide Temperature Stability & Low Friction |

| Medical & Food Production | Sterile Equipment Seals | Purity & Safety Compliance (e.g., FDA) |

| Electronics | Electrical Insulators | Superior Electrical Insulation |

Need a custom PTFE solution for your demanding application?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical balance of properties required for your unique environment.

Let us provide you with a reliable, custom-fabricated PTFE washer that delivers the chemical resistance, thermal stability, and purity your application demands. Contact our experts today to discuss your project, from prototype to high-volume production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs