In short, PTFE sheets are indispensable in nearly every high-performance industry, including chemical processing, aerospace, electronics, medical, and food and beverage. This material is not chosen for a single trait but for its unique combination of chemical inertness, temperature resistance, and exceptionally low friction, making it a problem-solver in the most demanding environments.

The widespread use of Polytetrafluoroethylene (PTFE) stems from a rare combination of three core properties: it is nearly impervious to chemical attack, stable across extreme temperatures, and has one of the lowest friction coefficients of any solid material. Understanding which of these properties is most critical for your application is the key to leveraging its power.

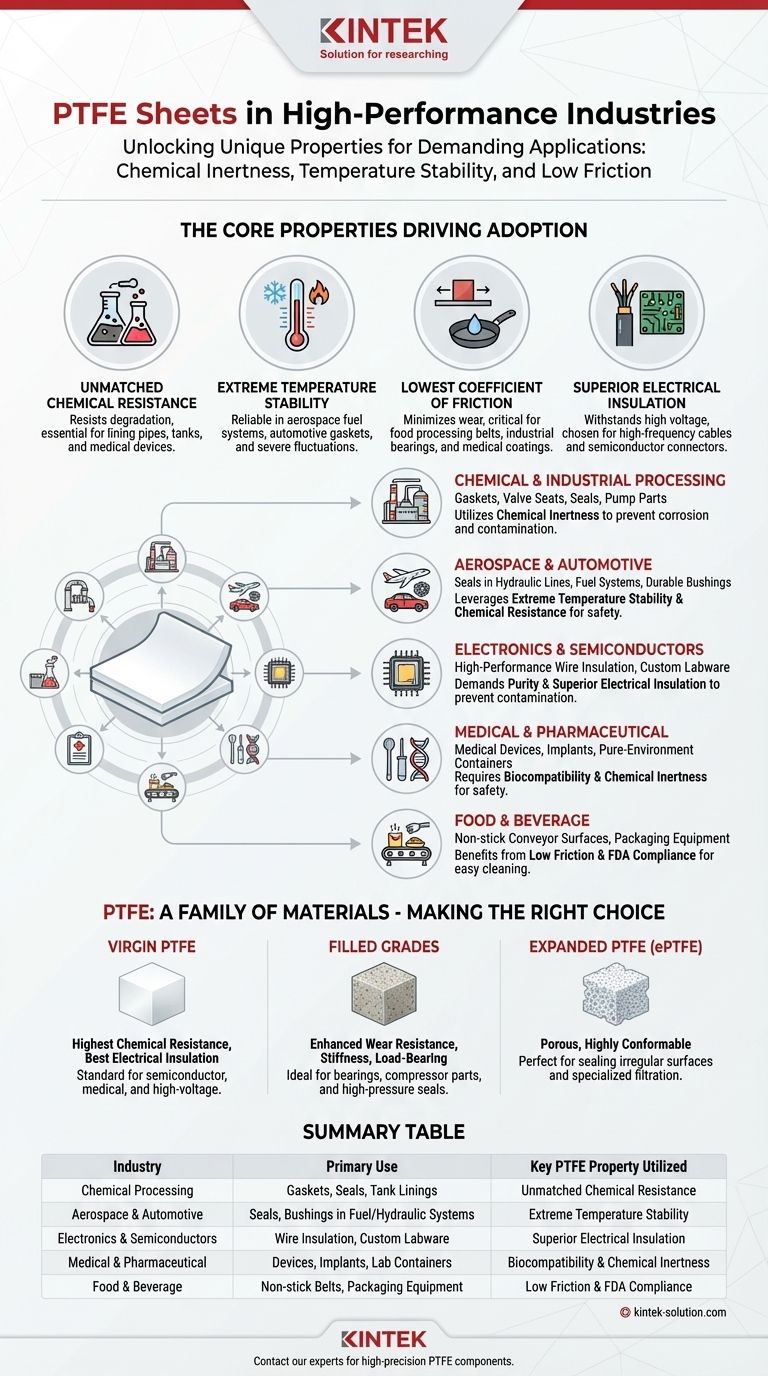

The Core Properties Driving PTFE Adoption

The versatility of PTFE is not accidental. It is a direct result of a few fundamental material characteristics that make it a default choice for engineers facing difficult challenges.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert substances known. It resists degradation from a vast range of aggressive chemicals, acids, and bases.

This property makes it essential for lining pipes, tanks, and vessels in the chemical processing industry and ensures biocompatibility for devices in the medical sector.

Extreme Temperature Stability

PTFE maintains its integrity and properties over an exceptionally wide temperature range. This allows it to perform reliably in applications involving cryogenic fluids or high-temperature processes.

You will find it used for seals in aerospace fuel systems and as durable gaskets in automotive engines where temperature fluctuations are constant and severe.

The Lowest Coefficient of Friction

Commonly known by its trade name Teflon®, PTFE’s surface is famously non-stick and slippery. This low-friction characteristic minimizes wear and energy loss in moving parts.

This is critical for non-stick surfaces on food processing conveyor belts, self-lubricating slide bearings in industrial machinery, and low-resistance coatings on medical devices.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with a high dielectric strength, meaning it can withstand high voltages without breaking down.

This makes it the material of choice for insulating high-frequency cables and connectors in the electronics and semiconductor industries, where signal integrity is paramount.

A Breakdown by Key Industries

While the core properties are the "why," the specific applications are the "what." Here is how different industries leverage PTFE sheets and components.

Chemical and Industrial Processing

This sector relies on PTFE's chemical inertness for gaskets, valve seats, seals, and pump parts. It prevents corrosion and contamination when handling aggressive substances.

Aerospace and Automotive

In these industries, PTFE is used for seals in hydraulic lines, aircraft fuel systems, and as durable bushings. Its ability to withstand harsh fluids and extreme temperatures is critical for safety and reliability.

Electronics and Semiconductors

The need for purity and electrical insulation drives PTFE use here. It is used for high-performance wire insulation and as custom labware and tools in semiconductor fabrication, where preventing contamination is essential.

Medical and Pharmaceutical

Biocompatibility and inertness are key. PTFE is used for medical devices, implants, prosthetics, and pure-environment research containers and funnels where non-reactivity with biological tissue or chemicals is non-negotiable.

Food and Beverage

The non-stick, FDA-compliant nature of PTFE makes it ideal for conveyor belt surfaces, packaging equipment, and other components that come into direct contact with food, ensuring easy release and cleaning.

Understanding the Trade-offs: PTFE is a Family of Materials

A common mistake is to view PTFE as a single material. In reality, its properties are often tailored with fillers to enhance performance for specific tasks. The choice of grade is a critical engineering decision.

Virgin PTFE vs. Filled Grades

Virgin PTFE is the pure, unmodified polymer. It offers the highest chemical resistance and best electrical insulation. However, it is relatively soft and can deform under load (a phenomenon known as "creep").

Filled grades add materials like glass fibers, bronze, or PEEK to the PTFE matrix. This dramatically increases wear resistance, stiffness, and load-bearing capability, but it may slightly reduce the absolute chemical resistance or insulating properties.

The Role of Expanded PTFE (ePTFE)

ePTFE is a modified form of PTFE that is porous and highly conformable. Its soft, flexible structure makes it an exceptional gasketing material for sealing rough or irregular pipe flanges in the chemical and oil/gas industries.

Its porous nature also makes it ideal for high-performance filters, where it can be used for environmental filtration and fluid purification.

Making the Right Choice for Your Application

Selecting the correct type of PTFE is crucial for project success. Your decision should be guided by the single most important demand of your application.

- If your primary focus is maximum chemical purity and electrical insulation: Virgin (unmodified) PTFE is the standard choice for applications in semiconductor, medical, and high-voltage electronics.

- If your primary focus is mechanical strength and wear resistance: A filled grade, such as glass-filled PTFE, is required for components like bearings, compressor parts, and high-pressure seals.

- If your primary focus is sealing irregular surfaces or specialized filtration: Expanded PTFE (ePTFE) provides the necessary conformability and porosity for demanding gaskets and advanced filters.

Ultimately, selecting the correct PTFE variant is key to leveraging its unique capabilities for your specific engineering challenge.

Summary Table:

| Industry | Primary Use of PTFE Sheets | Key PTFE Property Utilized |

|---|---|---|

| Chemical Processing | Gaskets, seals, tank linings | Unmatched chemical resistance |

| Aerospace & Automotive | Seals, bushings in fuel/hydraulic systems | Extreme temperature stability |

| Electronics & Semiconductors | Wire insulation, custom labware | Superior electrical insulation |

| Medical & Pharmaceutical | Medical devices, implants, lab containers | Biocompatibility and chemical inertness |

| Food & Beverage | Non-stick conveyor belts, packaging equipment | Low friction and FDA compliance |

Need a PTFE component that meets your exact specifications? KINTEK specializes in manufacturing high-precision PTFE components—from seals and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or a high-volume order, we deliver solutions that leverage PTFE's unique properties for your toughest challenges. Contact our experts today to discuss your application and get a custom quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications