In short, industries use PTFE lined diaphragm valves whenever they need to handle either ultra-pure or highly corrosive fluids without risk of contamination or chemical attack. The primary users are the pharmaceutical, biotech, food & beverage, and chemical processing sectors, which rely on the valve's unique combination of a chemically inert lining and a hygienic, pocket-free design.

The core challenge in many advanced industries is controlling aggressive or sensitive fluids while maintaining absolute process integrity. PTFE lined diaphragm valves are the definitive solution, as they merge the exceptional chemical resistance of PTFE with a mechanical design that eliminates crevices where contaminants or corrosive media could accumulate.

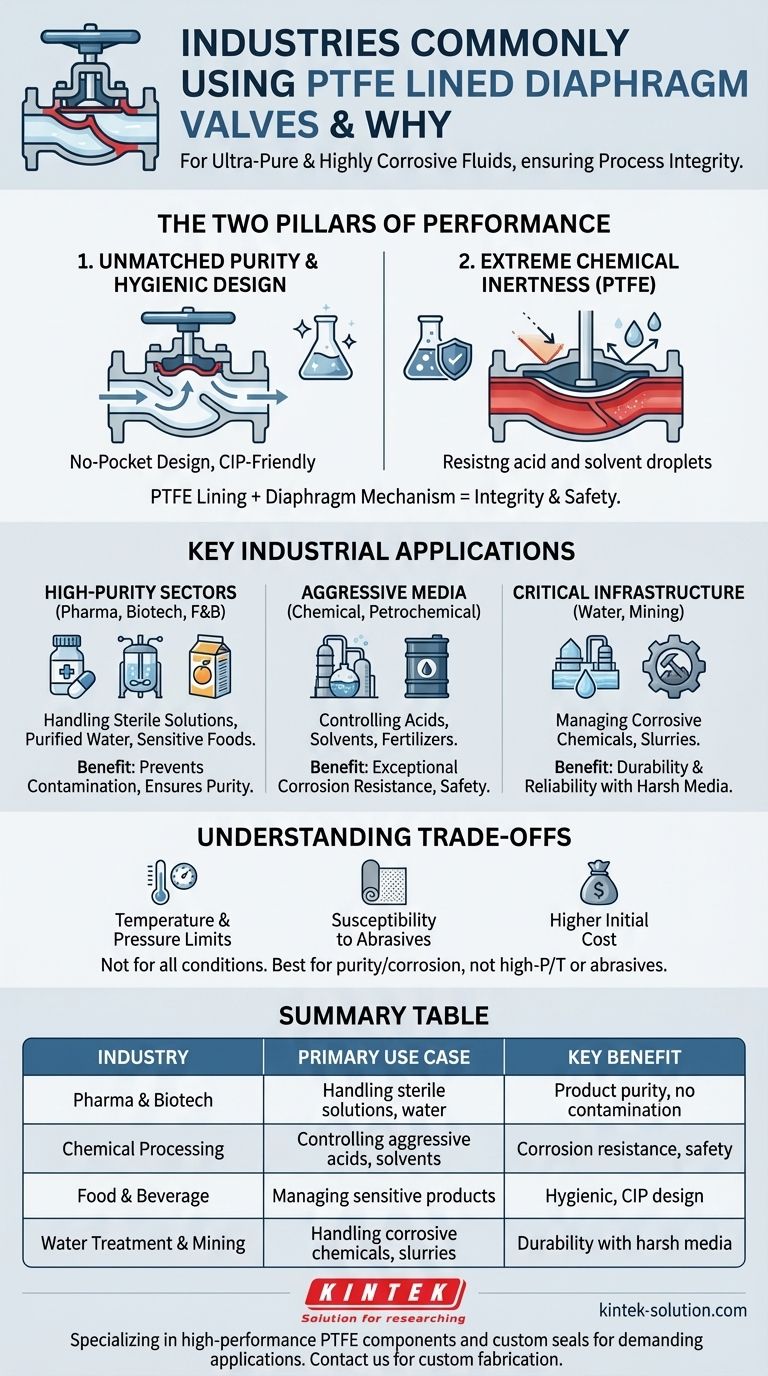

The Two Pillars of a PTFE Lined Diaphragm Valve

To understand why these valves are so critical, we need to look at their two fundamental advantages: the material of the lining (PTFE) and the mechanics of the valve (diaphragm).

Unmatched Purity and Hygienic Design

The diaphragm valve mechanism is inherently clean. A flexible diaphragm isolates the fluid from the valve's working parts (like the stem and actuator).

This creates a smooth, crevice-free internal pathway. There are no pockets or dead spaces for media to become trapped, which is essential for preventing bacterial growth or cross-contamination between batches.

This "no-pocket" design makes them ideal for Clean-in-Place (CIP) systems common in hygienic industries, where equipment must be thoroughly sanitized without disassembly.

Extreme Chemical Inertness

PTFE (Polytetrafluoroethylene) is one of the most chemically resistant materials known. It is effectively inert to nearly all industrial chemicals, acids, and solvents.

Lining the interior of a valve with PTFE protects the structural body (typically made of metal) from corrosion. This ensures the valve's longevity and, more importantly, prevents the fluid from being contaminated by leached metals.

This property makes them indispensable for handling aggressive and hazardous substances safely and efficiently.

Key Industrial Applications

Different industries leverage these valves to solve specific challenges related to their unique processes.

High-Purity Sectors: Pharma, Biotech, and Food & Beverage

For these industries, preventing contamination is the primary driver. The non-reactive, non-stick surface of PTFE combined with the valve's hygienic design ensures product purity.

They are used to handle purified water, sterile solutions, and sensitive food products like juices and dairy, where even minor contamination can ruin an entire batch.

Aggressive Media Sectors: Chemical and Petrochemical Processing

Here, the main concern is corrosion resistance and safety. These valves are used to control the flow of harsh chemicals, fertilizers, and petrochemicals.

The PTFE lining prevents the aggressive media from eating through the valve, ensuring operational safety and preventing costly and dangerous leaks.

Critical Infrastructure: Water Treatment and Mining

In wastewater and municipal water treatment, these valves handle corrosive chemicals like chlorine and other disinfectants with exceptional reliability.

In mining, they are used to manage corrosive slurries and chemical reagents used in metallurgical processes, where both chemical resistance and durability are required.

Understanding the Trade-offs

While highly effective, these valves are not a universal solution. Understanding their limitations is key to proper application.

Temperature and Pressure Limitations

PTFE is a polymer, and its performance is dependent on temperature and pressure. It has a lower operating temperature and pressure range compared to all-metal valves. Exceeding these limits can compromise the integrity of the lining.

Susceptibility to Abrasives

While excellent for corrosive fluids, PTFE is a relatively soft material. It is not ideal for services with sharp, highly abrasive particles, which can physically damage the lining over time and lead to failure.

Cost Considerations

PTFE lined diaphragm valves are specialized components. They often carry a higher initial cost than standard valves. However, this cost is frequently justified by their extended service life, reduced maintenance, and the prevention of process contamination or hazardous leaks.

Making the Right Choice for Your Process

The decision to use a PTFE lined diaphragm valve should be based on the specific demands of your application.

- If your primary focus is process purity and preventing contamination: These valves are the industry standard for ensuring hygienic, sterile, and contamination-free fluid handling.

- If your primary focus is handling highly corrosive chemicals safely: The inert PTFE lining offers unparalleled protection against chemical attack, making it a superior choice for safety and long-term reliability.

- If your primary focus is on high-pressure or high-temperature service with non-corrosive media: A standard metal valve, such as a globe or ball valve, is likely a more suitable and cost-effective option.

Ultimately, selecting the correct valve is about matching the engineering to the specific chemical and physical demands of your system to ensure safety and integrity.

Summary Table:

| Industry | Primary Use Case | Key Benefit |

|---|---|---|

| Pharmaceutical & Biotech | Handling sterile solutions, purified water | Ensures product purity, prevents contamination |

| Chemical Processing | Controlling aggressive acids, solvents | Exceptional corrosion resistance, safety |

| Food & Beverage | Managing sensitive products (juices, dairy) | Hygienic, clean-in-place (CIP) design |

| Water Treatment & Mining | Handling corrosive chemicals, slurries | Durability and reliability with harsh media |

Need a reliable valve for aggressive or ultra-pure fluids?

KINTEK specializes in manufacturing high-performance PTFE components, including custom seals and liners for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your equipment handles corrosive or sensitive media safely and without contamination.

Contact us today to discuss your specific requirements for custom fabrication, from prototypes to high-volume orders. Let our expertise enhance your process integrity and safety.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance