The industries that benefit most from PTFE expansion bellows are those that operate in chemically aggressive, high-purity, or high-temperature environments. This includes chemical processing, pharmaceuticals, semiconductor manufacturing, and food and beverage production, where material integrity and non-contamination are paramount for both safety and product quality.

The core reason these industries rely on PTFE bellows is not just for flexibility, but for risk mitigation. The unique combination of near-universal chemical inertness, high-purity surfaces, and thermal stability makes PTFE the default choice when component failure or contamination would lead to catastrophic system damage, production loss, or safety hazards.

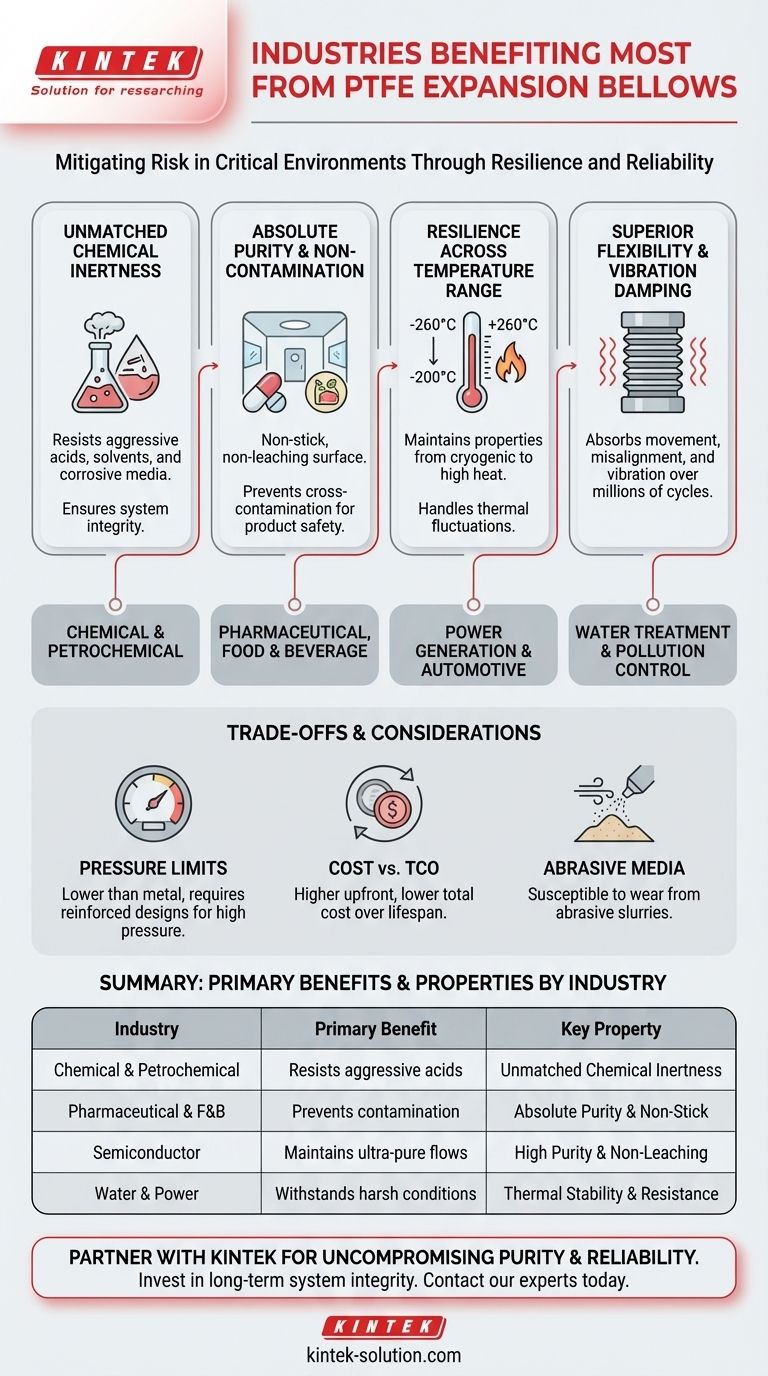

Why PTFE Dominates in Critical Environments

The selection of a material for an expansion bellow in a critical system is a decision based on resilience and reliability. PTFE (Polytetrafluoroethylene) possesses a unique set of properties that makes it indispensable for demanding applications where lesser materials would quickly degrade.

Unmatched Chemical Inertness

PTFE is renowned for being resistant to nearly all industrial chemicals, acids, and solvents. This makes it the primary choice for systems that transport or process highly corrosive media.

Unlike metal or rubber alternatives that can corrode or degrade, PTFE remains stable, preventing dangerous leaks and costly downtime in chemical and petrochemical plants.

Absolute Purity and Non-Contamination

The surface of PTFE is exceptionally non-stick and non-leaching. It does not impart any taste, color, or contaminants into the media it contacts.

This property is non-negotiable in industries like pharmaceuticals, food and beverage, and semiconductor manufacturing. It ensures product purity, prevents cross-contamination between batches, and is critical for creating the ultra-clean environments required for sensitive processes.

Resilience Across a Wide Temperature Range

PTFE maintains its properties across a broad spectrum of temperatures, from cryogenic levels up to sustained high-heat applications.

This thermal stability is crucial in power generation, automotive, and various chemical processing applications where piping systems experience significant temperature fluctuations that could cause other materials to become brittle or fail.

Superior Flexibility and Vibration Damping

Expansion bellows are designed to absorb movement, misalignment, and vibration within a piping system. PTFE’s flexibility allows it to perform this function reliably over millions of cycles.

This is vital in complex piping networks, HVAC systems, and on equipment like pumps and compressors to isolate vibration, reduce noise, and protect the overall system from mechanical stress.

A Closer Look at Key Industrial Applications

Understanding the specific problems that PTFE bellows solve within each industry clarifies why they are so widely adopted.

In Chemical and Petrochemical Processing

The primary challenge in this sector is corrosion. PTFE bellows safely handle aggressive fluids like sulfuric acid, chlorine, and benzene, protecting the integrity of the piping system and ensuring worker safety. They prevent costly shutdowns caused by component failure.

In Pharmaceuticals and Food & Beverage

Here, the goal is to prevent contamination at all costs. PTFE's non-stick surface resists the buildup of biological matter (biofilm) and simplifies clean-in-place (CIP) procedures, ensuring the final product remains sterile and unadulterated.

In Semiconductor and High-Tech Manufacturing

The manufacturing of microchips requires ultra-pure water and chemicals. Any microscopic particle leached from a component can ruin an entire batch of wafers. PTFE bellows provide the necessary purity, ensuring no foreign materials are introduced into these sensitive processes.

In Water Treatment and Pollution Control

These systems often use harsh chemicals like ozone, chlorine, and various acids to treat water and scrub pollutants from emissions. PTFE bellows withstand this constant chemical exposure, offering a long service life where metal or rubber would quickly fail.

Understanding the Trade-offs and Considerations

While highly effective, PTFE is not a universal solution. Acknowledging its limitations is key to its proper application.

Mechanical Strength and Pressure Limits

Compared to metal expansion joints, standard PTFE bellows have lower tensile strength and pressure ratings. For extremely high-pressure applications, reinforced or specialized designs may be necessary.

Cost vs. Total Cost of Ownership

The upfront material cost of PTFE can be higher than that of some rubber or basic metal alternatives. However, its exceptional lifespan and elimination of maintenance in corrosive environments often result in a significantly lower total cost of ownership over the life of the system.

Susceptibility to Abrasive Media

While chemically inert, PTFE is a relatively soft material. It can be susceptible to wear in systems transporting highly abrasive slurries, which may require alternative solutions or specialized liners.

Making the Right Choice for Your Application

Your final decision should be driven by the primary demand of your system.

- If your primary focus is handling aggressive chemicals: PTFE is the safest and most reliable choice due to its near-universal chemical inertness.

- If your primary focus is maintaining absolute product purity: PTFE's non-leaching and non-stick properties are essential for preventing contamination in sanitary applications.

- If your primary focus is system longevity in corrosive or high-heat environments: PTFE's durability drastically reduces maintenance cycles and the risk of unexpected failure.

- If your primary focus is vibration damping in a challenging chemical environment: PTFE provides the necessary flexibility without succumbing to the chemical attacks that would degrade other flexible materials.

Ultimately, selecting PTFE expansion bellows is a strategic investment in the safety, purity, and long-term reliability of your most critical systems.

Summary Table:

| Industry | Primary Benefit of PTFE Bellows | Key Property Utilized |

|---|---|---|

| Chemical & Petrochemical | Resists aggressive acids and solvents | Unmatched Chemical Inertness |

| Pharmaceutical & Food & Beverage | Prevents contamination, ensures product purity | Absolute Purity & Non-Stick Surface |

| Semiconductor Manufacturing | Maintains ultra-pure water/chemical flows | High Purity & Non-Leaching |

| Water Treatment & Power Generation | Withstands harsh chemicals and temperature swings | Thermal Stability & Chemical Resistance |

Ready to enhance the reliability and purity of your critical systems?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom expansion bellows. We serve demanding industries like semiconductor, medical, laboratory, and industrial processing, where failure is not an option.

Partner with KINTEK for:

- Uncompromising Purity: Ideal for pharmaceutical, food, beverage, and semiconductor applications.

- Superior Chemical Resistance: Confidently handle the most aggressive media in chemical processing.

- Custom Fabrication: From prototypes to high-volume orders, we tailor solutions to your exact specifications.

Invest in long-term system integrity. Contact our experts today to discuss your specific requirements and receive a custom solution quote.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key chemical properties of PTFE balls? Unmatched Chemical & Thermal Stability

- What are the overall advantages of using PTFE balls in fluid management systems? Enhance Reliability & Efficiency

- How do PTFE balls contribute to reduced maintenance costs? Extend Component Life and Cut Downtime

- In which industries are Teflon (PTFE) balls commonly used? Key Applications & Benefits

- What factors determine the different grades of PTFE balls available? Select the Right Grade for Your Application