In short, industries operating in extreme environments benefit most from using PTFE rotary seals. Key sectors include aerospace and defense, oil and gas, food and pharmaceutical processing, and heavy industrial manufacturing, where standard seals fail due to high pressure, extreme temperatures, aggressive chemicals, or high rotational speeds.

The decision to use a PTFE rotary seal is driven by operational demands that exceed the capabilities of traditional elastomeric seals. Industries choose PTFE not as a general-purpose solution, but as a specific engineering solution for challenges involving chemical aggression, extreme temperatures, high surface speeds, or stringent purity requirements.

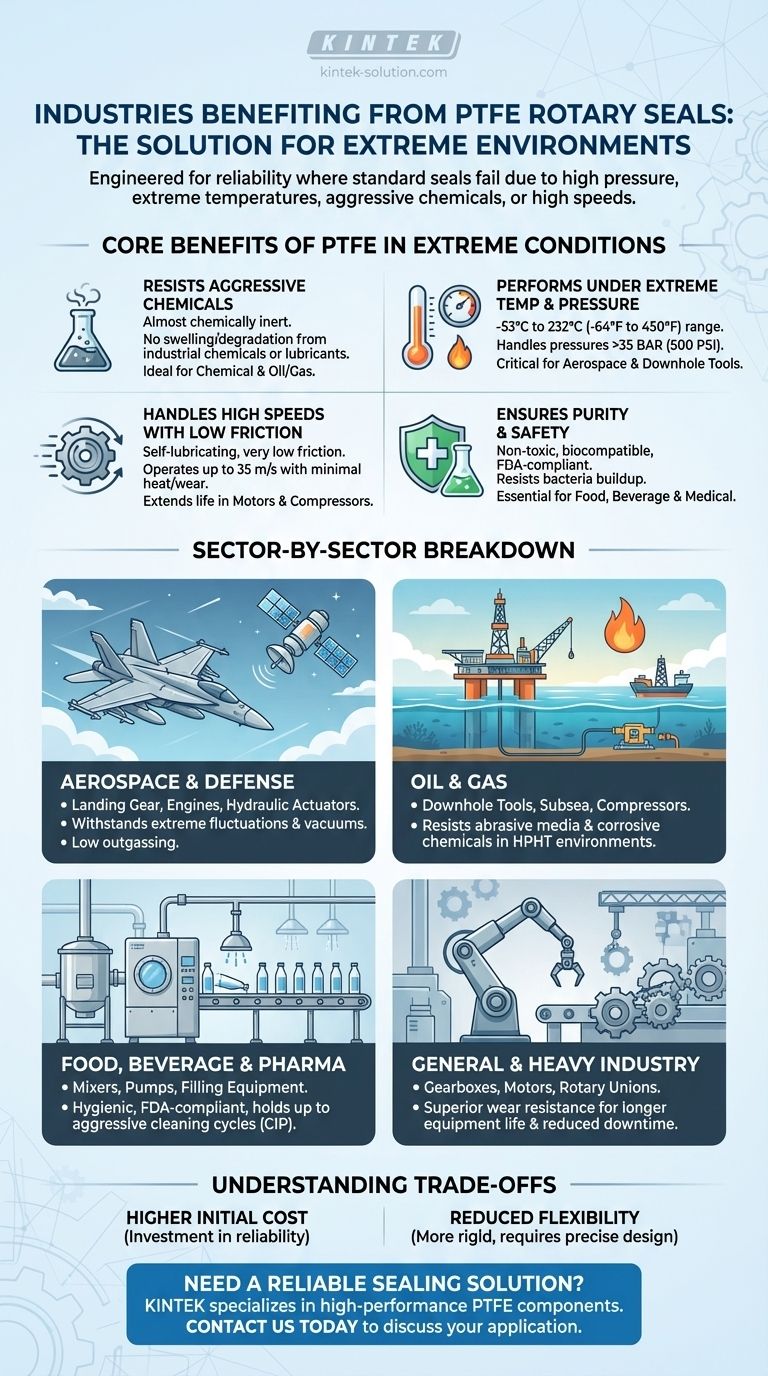

Why PTFE is the Solution for Extreme Conditions

The value of a PTFE seal lies in its fundamental material properties. It provides a unique combination of characteristics that allows equipment to function reliably where other materials would quickly degrade and fail.

Resisting Aggressive Chemicals and Fluids

PTFE is almost entirely chemically inert. This makes it indispensable in the chemical, oil and gas, and pharmaceutical industries.

It will not swell, soften, or degrade when exposed to the vast majority of industrial chemicals, lubricants, and aggressive cleaning agents.

Performing Under Extreme Temperatures and Pressures

PTFE seals maintain their integrity and sealing capability across a massive temperature range, typically from -53°C to 232°C (-64°F to 450°F).

They are also engineered to handle pressures exceeding 35 BAR (500 PSI), making them critical for high-pressure hydraulic and pneumatic systems in aerospace and downhole oil tools.

Handling High Speeds with Low Friction

Unlike rubber seals, PTFE has an extremely low coefficient of friction. This self-lubricating property allows PTFE seals to operate at high rotational velocities (up to 35 m/s) with minimal heat generation and wear.

This is a critical advantage in high-speed equipment like motors, gearboxes, compressors, and rotary unions, where it extends the seal's lifespan and reduces maintenance.

Ensuring Purity and Safety

In the food, beverage, and medical industries, material purity is non-negotiable. PTFE is non-toxic, biocompatible, and can be manufactured to be FDA-compliant.

Its non-stick surface resists the buildup of media and bacteria, making it ideal for sterile process equipment, mixers, pumps, and even surgical tools.

A Sector-by-Sector Breakdown

Seeing how PTFE seals are applied in specific industries highlights their problem-solving capabilities.

Aerospace and Defense

In this sector, reliability is paramount. PTFE seals are used in landing gear systems, engine components, hydraulic actuators, and pumps.

Their ability to withstand extreme temperature fluctuations, high pressures, and aggressive hydraulic fluids is essential. Furthermore, PTFE's low outgassing properties are crucial for components used in vacuum or near-vacuum environments.

Oil and Gas

The oil and gas industry subjects equipment to some of the harshest conditions, known as High-Pressure High-Temperature (HPHT) environments.

PTFE seals are used in downhole tools, subsea equipment, compressors, and rotary valves where they must resist abrasive media and corrosive chemicals under immense pressure.

Food, Beverage, and Pharmaceutical

Hygiene and compliance are the primary drivers here. PTFE seals are found in mixers, pumps, filling equipment, and clean-in-place (CIP) systems.

Their chemical resistance stands up to aggressive cleaning cycles, and their non-toxic nature ensures product purity is maintained in everything from autoclaves to hematology analyzers.

General and Heavy Industry

From robotics to construction machinery, durability is key. PTFE seals are used in gearboxes, motors, rotary unions, and centrifuges.

Their superior wear resistance translates directly to longer equipment life, reduced downtime, and lower maintenance costs, especially in high-duty cycle applications.

Understanding the Trade-offs

While PTFE offers superior performance in demanding situations, it is not a universal replacement for all seal types.

Higher Initial Cost

PTFE seals are typically more expensive than their traditional elastomeric (rubber) counterparts. Their use is an investment in reliability and longevity where the cost of failure is high.

Reduced Flexibility

Compared to rubber, PTFE is a more rigid material. This can sometimes make installation more complex and requires precise housing designs to ensure an effective seal. It may not be the ideal choice for applications with significant shaft runout or housing imperfections.

Making the Right Choice for Your Application

Selecting the right seal requires a clear understanding of your operational goals.

- If your primary focus is extreme environments: PTFE is the superior choice for reliability in applications with high temperatures, high pressures, or high rotational speeds.

- If your primary focus is chemical compatibility: PTFE's chemical inertness prevents seal degradation and protects your process from contamination.

- If your primary focus is purity and hygiene: PTFE's non-toxic and FDA-compliant grades are essential for any food, beverage, or medical application.

- If your primary focus is cost on a standard application: A traditional elastomeric seal may be more economical if extreme conditions are not a factor.

Ultimately, choosing a PTFE seal is a strategic decision to engineer failure out of your most critical and demanding applications.

Summary Table:

| Industry | Key Benefit of PTFE Seals |

|---|---|

| Aerospace & Defense | Extreme temperature/pressure resistance, low outgassing |

| Oil & Gas | HPHT environment resilience, chemical/abrasion resistance |

| Food, Beverage & Pharma | Non-toxic, FDA-compliant, hygienic, easy to clean |

| Heavy Industrial | High-speed capability, low friction, long service life |

Need a reliable sealing solution for your extreme application?

KINTEK specializes in manufacturing high-performance, precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders to meet your specific requirements.

Contact us today to discuss how our PTFE seals can enhance your equipment's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech