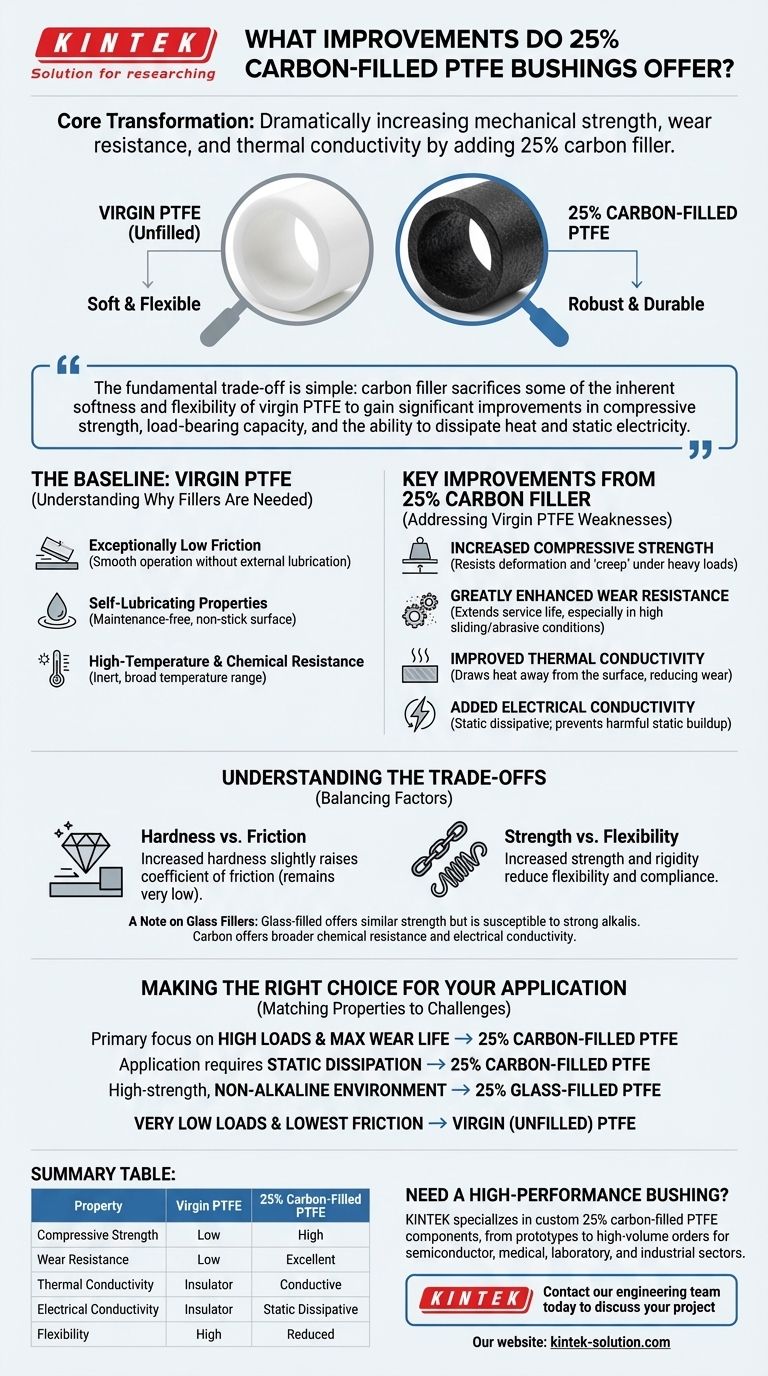

At its core, adding 25% carbon filler to Polytetrafluoroethylene (PTFE) transforms the material by dramatically increasing its mechanical strength, wear resistance, and thermal conductivity. This enhancement turns a soft, self-lubricating plastic into a robust bearing material capable of handling demanding applications where unfilled PTFE would fail.

The fundamental trade-off is simple: carbon filler sacrifices some of the inherent softness and flexibility of virgin PTFE to gain significant improvements in compressive strength, load-bearing capacity, and the ability to dissipate heat and static electricity.

The Baseline: Understanding Virgin PTFE

Before analyzing the role of carbon filler, it's essential to understand the inherent properties of pure, or "virgin," PTFE. This context explains why fillers are necessary for many mechanical applications.

### Exceptionally Low Friction

PTFE is renowned for its extremely low coefficient of friction, one of the lowest of any solid material. This allows it to operate smoothly without external lubrication.

### Self-Lubricating Properties

The material's unique non-stick characteristics mean it provides a maintenance-free, self-lubricating surface, which reduces operational costs and complexity.

### High-Temperature and Chemical Resistance

PTFE maintains its properties across a wide temperature range and is chemically inert to most substances, making it suitable for harsh environments.

Key Improvements from 25% Carbon Filler

Adding a 25% carbon filler directly addresses the primary weaknesses of virgin PTFE—its softness and tendency to deform under pressure.

### Increased Compressive Strength

The primary benefit is a significant boost in compressive strength. This allows the bushings to resist deformation and "creep" when subjected to heavy, sustained loads.

### Greatly Enhanced Wear Resistance

Carbon-filled PTFE offers far greater wear tolerance. This extends the service life of the bushing, especially in applications with high sliding velocities or abrasive conditions.

### Improved Thermal Conductivity

Pure PTFE is a thermal insulator, which can lead to heat buildup at the bearing surface. Carbon filler makes the material thermally conductive, allowing it to draw heat away from the surface and reduce wear.

### Added Electrical Conductivity

The carbon filler also imparts electrical conductivity, making the material static dissipative. This is a critical feature in applications where a buildup of static electricity could be damaging or hazardous.

Understanding the Trade-offs

While fillers provide clear advantages, it's important to recognize that they also alter the material's original properties. Choosing the right material involves balancing these factors.

### Hardness vs. Friction

Adding any filler, including carbon or glass, increases the hardness of the PTFE. This can slightly increase the coefficient of friction compared to virgin PTFE, though it remains very low.

### Strength vs. Flexibility

The increased strength and rigidity from fillers like carbon and glass come at the cost of reduced flexibility. The material becomes less compliant, which must be considered in the design.

### A Note on Glass Fillers

For comparison, 25% glass-filled PTFE also offers increased strength and durability. However, it can be attacked by strong alkalis, whereas carbon provides broader chemical resistance and the unique benefit of electrical conductivity.

Making the Right Choice for Your Application

Your final material selection depends entirely on the specific demands of your operating environment.

- If your primary focus is handling high loads and maximizing wear life: 25% carbon-filled PTFE is an excellent choice due to its superior compressive strength and durability.

- If your application requires static dissipation: 25% carbon-filled PTFE is the definitive option, as neither virgin nor glass-filled variants are conductive.

- If you need a high-strength alternative for a non-alkaline environment: 25% glass-filled PTFE offers comparable strength and may be a suitable alternative.

- If your application involves very low loads and the absolute lowest friction is paramount: Virgin (unfilled) PTFE may be sufficient for your needs.

Choosing the correct bushing material is about matching the engineering properties to the specific challenges of the application.

Summary Table:

| Property | Virgin PTFE | 25% Carbon-Filled PTFE |

|---|---|---|

| Compressive Strength | Low | High |

| Wear Resistance | Low | Excellent |

| Thermal Conductivity | Insulator | Conductive |

| Electrical Conductivity | Insulator | Static Dissipative |

| Flexibility | High | Reduced |

Need a high-performance bushing for a demanding application?

KINTEK specializes in manufacturing precision PTFE components, including custom 25% carbon-filled bushings, seals, and liners. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a component perfectly matched to your specific requirements in the semiconductor, medical, laboratory, or industrial sectors.

Contact our engineering team today to discuss your project and discover how our materials expertise can enhance your design's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Three Neck Flasks for Advanced Chemical Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications