From the kitchen to the factory floor, the impact of Polytetrafluoroethylene (PTFE) industrial coatings on daily life is profound and often invisible. This material, most famously known by the brand name Teflon, is a hidden workhorse whose unique properties—extreme slipperiness, heat tolerance, and chemical inertness—have enabled countless industrial processes and modern conveniences that we now take for granted.

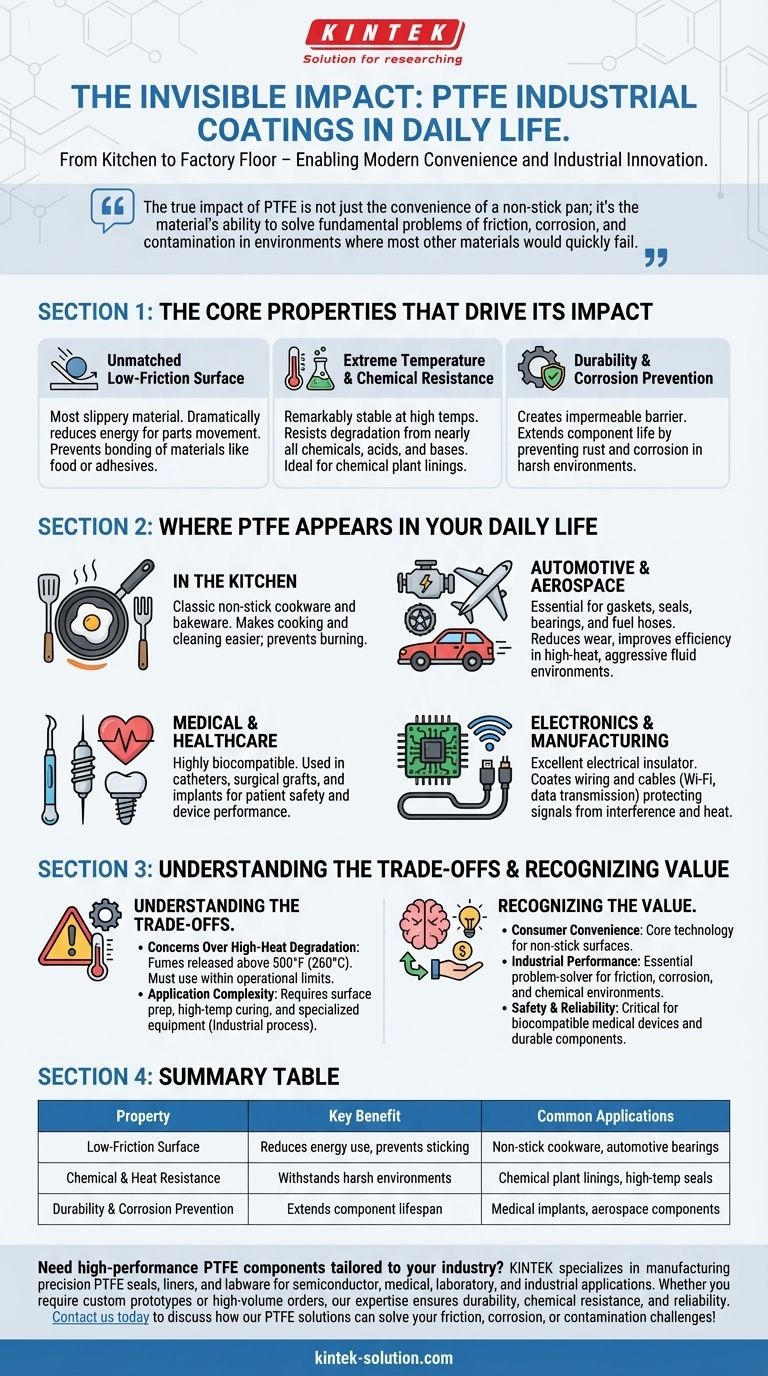

The true impact of PTFE is not just the convenience of a non-stick pan; it's the material's ability to solve fundamental problems of friction, corrosion, and contamination in environments where most other materials would quickly fail.

The Core Properties That Drive Its Impact

The widespread adoption of PTFE stems from a combination of three powerful physical properties. Understanding these explains why it appears in such a diverse range of applications.

Unmatched Low-Friction Surface

PTFE is one of the most slippery materials known to science, giving it an exceptionally low coefficient of friction.

This "non-stick" quality is the most famous benefit. It dramatically reduces the energy needed for parts to slide past one another and prevents materials, from food to industrial adhesives, from bonding to a surface.

Extreme Temperature and Chemical Resistance

PTFE is remarkably stable, remaining effective at very high temperatures and resisting degradation from nearly all common chemicals, acids, and bases.

This chemical inertness makes it an ideal lining for pipes, tanks, and vessels in chemical plants that handle highly corrosive substances. It ensures purity and prevents the container itself from being destroyed.

Durability and Corrosion Prevention

As a coating, PTFE creates an impermeable barrier that protects the underlying material (usually metal) from moisture and corrosive agents.

This property significantly extends the life of components. It prevents rust and other forms of corrosion on industrial and automotive parts that are exposed to harsh environmental conditions, reducing failure rates and maintenance costs.

Where PTFE Appears in Your Daily Life

While cookware is the most recognized application, PTFE's true value is demonstrated in the critical, high-performance roles it plays across many industries.

In the Kitchen

This is the classic example. Non-stick coatings on frying pans, bakeware, and utensils make cooking and cleaning far easier by preventing food from burning onto the surface.

In Automotive and Aerospace

PTFE is essential for reducing wear and improving efficiency. It is used in gaskets, seals, bearings, and fuel hoses where its low friction and resistance to aggressive fluids and high temperatures are critical for reliability.

In Medical and Healthcare

Because the human body does not react to it, PTFE is considered highly biocompatible. This makes it an ideal material for catheters, surgical grafts, and implants, ensuring patient safety and device performance.

In Electronics and Manufacturing

PTFE is an excellent electrical insulator. It is used to coat wiring and cables, particularly for high-frequency applications like Wi-Fi and data transmission, protecting signals from interference and heat damage.

Understanding the Trade-offs

No material is perfect, and being an effective advisor means acknowledging limitations. While incredibly useful, PTFE has specific considerations.

Concerns Over High-Heat Degradation

The primary concern associated with PTFE involves its performance at extreme temperatures. When heated well above normal cooking temperatures (over 500°F or 260°C), the coating can begin to break down and release fumes.

For its intended applications, from cookware to industrial parts, this is rarely an issue. It simply means the material must be used within its specified operational limits.

Application Complexity

Applying a PTFE coating is not a simple painting process. It requires surface preparation, high-temperature curing, and specialized equipment to ensure a proper bond and a flawless finish. This makes it a solution for industrial manufacturing rather than a simple DIY fix.

Recognizing the Value of PTFE

To grasp its full impact, it helps to view PTFE's contributions through the lens of the problem it solves in different contexts.

- If your primary focus is consumer convenience: Recognize PTFE as the core technology behind non-stick surfaces that dramatically simplify daily tasks like cooking and cleaning.

- If your primary focus is industrial performance: View PTFE as an essential problem-solver for reducing friction, preventing corrosion, and handling extreme chemical environments safely and reliably.

- If your primary focus is safety and reliability: Appreciate its role in creating biocompatible medical devices and durable, long-lasting components for critical systems like vehicles and aircraft.

Ultimately, PTFE is a premier example of a material science breakthrough whose unique properties have enabled a cascade of innovation across nearly every modern industry.

Summary Table:

| Property | Key Benefit | Common Applications |

|---|---|---|

| Low-Friction Surface | Reduces energy use, prevents sticking | Non-stick cookware, automotive bearings |

| Chemical & Heat Resistance | Withstands harsh environments | Chemical plant linings, high-temp seals |

| Durability & Corrosion Prevention | Extends component lifespan | Medical implants, aerospace components |

Need high-performance PTFE components tailored to your industry? KINTEK specializes in manufacturing precision PTFE seals, liners, and labware for semiconductor, medical, laboratory, and industrial applications. Whether you require custom prototypes or high-volume orders, our expertise ensures durability, chemical resistance, and reliability. Contact us today to discuss how our PTFE solutions can solve your friction, corrosion, or contamination challenges!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts