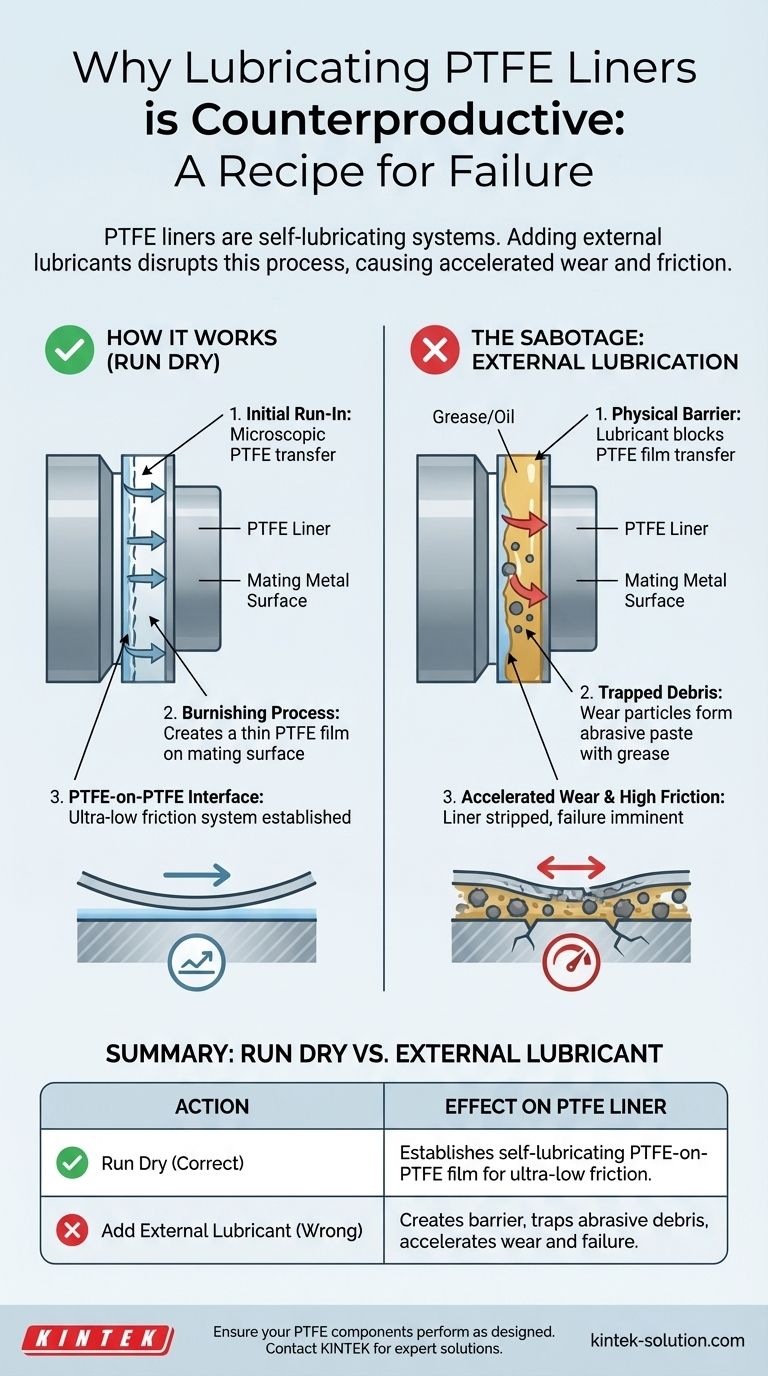

In short, applying external lubricants to a PTFE liner is counterproductive. It interferes with the material's inherent self-lubricating properties, which blocks the essential "burnishing" action required for low-friction operation. This ultimately leads to accelerated wear and a drastic increase in friction, defeating the entire purpose of using a PTFE liner.

The core principle to understand is that PTFE liners are not just low-friction surfaces; they are self-lubricating systems. Adding an external lubricant sabotages this system, transforming a solution into a problem.

The Self-Lubricating Mechanism of PTFE

To understand why external lubricants cause failure, you must first understand how a PTFE liner is designed to function on its own.

How PTFE Liners Work: The Burnishing Process

A PTFE liner doesn't just provide a slippery surface. During the initial run-in period, it works by transferring a microscopic, thin film of its own material onto the mating metal surface.

This transfer process is known as burnishing. It effectively coats the opposing surface with PTFE.

The Result: An Ultra-Low Friction System

Once this transfer film is established, the system operates as a PTFE surface sliding against another PTFE surface. This "PTFE-on-PTFE" interface is what creates the extremely low coefficient of friction the material is known for.

This self-replenishing film is the key to the liner's long-term, maintenance-free performance.

How External Lubricants Sabotage This Process

Introducing grease or oil into this system fundamentally disrupts its designed function, leading to a cascade of negative effects.

Creating a Physical Barrier

An external lubricant, like grease, forms a film that acts as a physical barrier between the PTFE liner and the mating surface.

This barrier prevents the burnishing process from occurring. The liner cannot transfer its lubricating film, so the low-friction "PTFE-on-PTFE" system is never established.

Trapping Wear Debris

As the now-unlubricated liner face inevitably wears, the small particles of PTFE are not cleared away. Instead, they become trapped in the sticky grease or oil.

This mixture of liner debris and lubricant can form a thick, abrasive paste. This paste dramatically accelerates wear, grinding away the liner much faster than if it were running dry.

The Paradox of Increased Friction

The initial attempt to reduce friction by adding a lubricant results in the opposite outcome. The protective PTFE film cannot form, and the abrasive paste actively increases wear.

Ultimately, the PTFE material is stripped from the liner face, leading to high-friction metal-on-metal or metal-on-backing contact and complete failure of the component.

Common Pitfalls and Misconceptions

The confusion often arises because PTFE is associated with lubrication in other contexts. It's crucial to distinguish between these applications.

Misconception 1: PTFE as a Lubricant Additive

PTFE is often used as a solid additive within oils and greases (for example, in some bicycle chain lubricants). In this case, it is part of a formulated product. This is entirely different from applying that product to a solid PTFE liner designed to run dry.

Misconception 2: Lubrication in Machining

During the machining or manufacturing of parts, lubricants and coolants are essential. They reduce cutting heat and friction to ensure a quality surface finish. This is a temporary manufacturing aid, not a guideline for the component's operational life.

How to Apply This to Your Components

Your approach should be guided by the design of the component, not by a general impulse to lubricate anything that moves.

- If your component is designed with a solid PTFE liner: It is engineered to be self-lubricating and should be run dry. Do not add any external grease or oil.

- If a PTFE-lined component becomes noisy or stiff: This is a sign of wear. The solution is to inspect and replace the liner, not to add a lubricant which will only mask the problem and accelerate the failure.

- If you are using a lubricant fortified with PTFE: Understand that you are using a formulated product where PTFE is an additive, which is a valid but entirely different application from a solid, self-lubricating liner.

Trust the material's design to do its job without interference.

Summary Table:

| Action | Effect on PTFE Liner |

|---|---|

| Run Dry (Correct) | Establishes a PTFE-on-PTFE film via burnishing for ultra-low friction. |

| Add External Lubricant | Creates a barrier preventing burnishing, traps abrasive debris, and accelerates wear. |

Ensure your PTFE components perform as designed.

At KINTEK, we specialize in manufacturing high-precision PTFE seals, liners, and labware for the semiconductor, medical, and industrial sectors. Our components are engineered for optimal, maintenance-free performance. Don't let improper lubrication compromise your equipment.

Contact our experts today for custom fabrication from prototypes to high-volume orders. We'll help you select the right PTFE solution to avoid premature failure and maximize operational efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support