When clearance develops in a PTFE-lined bearing, it indicates the beginning of a rapid failure process. This initial looseness allows contaminants like dirt and grit to enter the space between the ball and the liner. This contamination, combined with the loss of the bearing's self-lubricating surface, quickly compromises its function and means the bearing must be replaced.

The critical issue with clearance in a PTFE-lined bearing is not the looseness itself, but how it destroys the self-lubricating system. Once the tight, intimate contact required to maintain the PTFE transfer film is lost, abrasive wear accelerates, leading to irreversible failure.

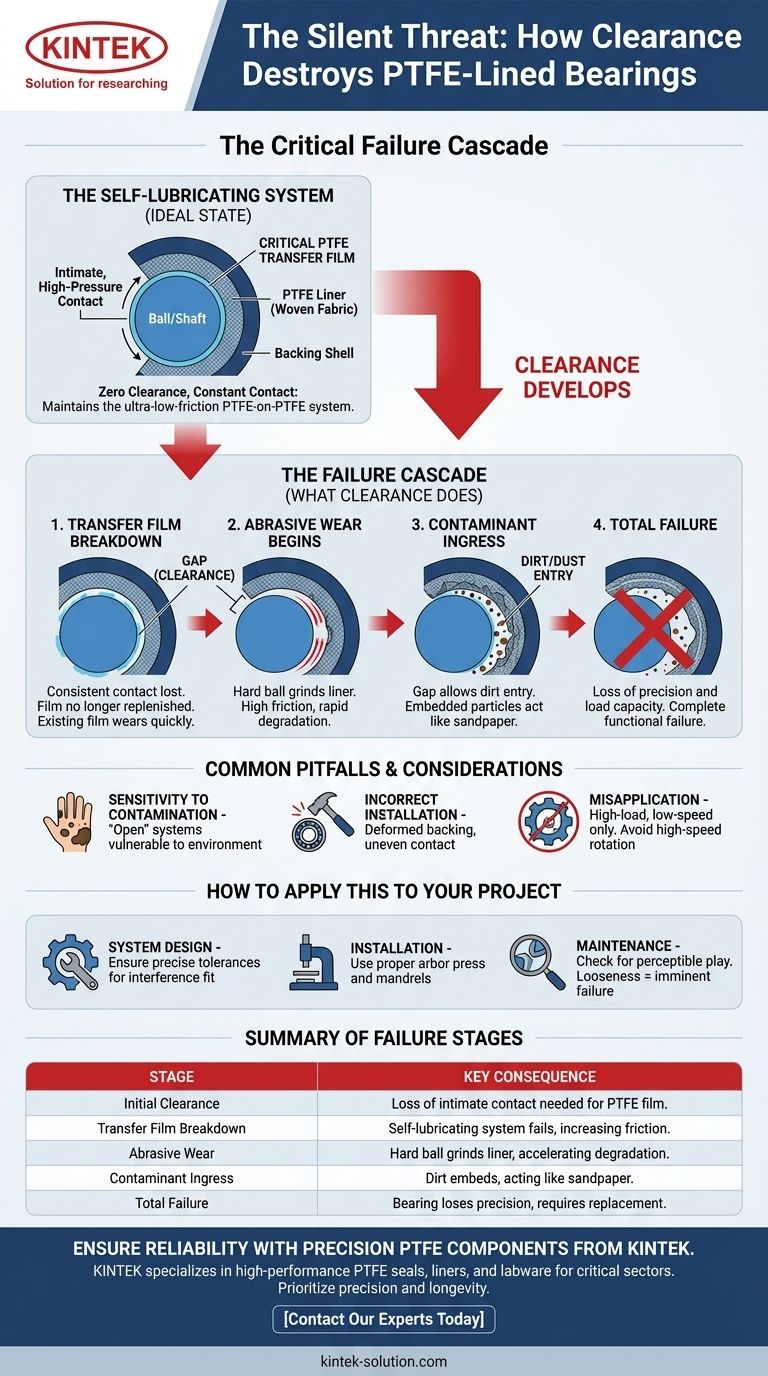

The Self-Lubricating System: How It's Supposed to Work

To understand why clearance is so catastrophic, we first need to understand the bearing's core mechanism. These are not traditional bearings that rely on grease or oil.

The PTFE Liner

The "liner" is typically a fabric woven from PTFE (Polytetrafluoroethylene) fibers and other structural fibers, bonded to a rigid backing shell. PTFE is known for its extremely low coefficient of friction.

The Critical Transfer Film

During the initial break-in cycles of the bearing, microscopic amounts of the PTFE liner transfer onto the surface of the mating ball or shaft. This creates a thin, stable PTFE transfer film.

The result is an ultra-low-friction system of PTFE sliding against PTFE. This is the "self-lubricating" feature.

The Necessity of a Tight Fit

This entire system depends on intimate, high-pressure contact between the ball and the liner. These bearings are designed to operate with zero clearance, and often with a specific amount of preload (a negative clearance). This constant contact is what maintains the crucial transfer film.

The Failure Cascade: What Clearance Actually Does

When clearance (unwanted looseness) develops, it systematically dismantles the self-lubricating mechanism.

Step 1: The Transfer Film Breaks Down

With clearance, the consistent, high-pressure contact is lost. The ball is no longer continuously rubbing against the liner, which means the PTFE transfer film is no longer being replenished. The existing film on the ball quickly wears away.

Step 2: Abrasive Wear Begins

Once the transfer film is gone, the system is no longer PTFE-on-PTFE. It becomes the hard material of the ball grinding directly against the softer fibers of the liner. This creates high friction and introduces abrasive wear, which rapidly degrades the liner.

Step 3: Contaminant Ingress

The new gap acts as an entry point for dirt, dust, and moisture. These contaminants become embedded in the soft liner material, turning it into a piece of sandpaper that grinds against the ball with every movement, drastically accelerating wear.

Step 4: Total Failure

This cycle of wear, increased clearance, and further contamination accelerates exponentially. The bearing quickly loses all precision and load-carrying capacity, resulting in complete functional failure.

Common Pitfalls and Considerations

While effective, PTFE-lined bearings have specific vulnerabilities that can lead to premature clearance and failure.

Sensitivity to Contamination

Because they are "open" systems, they are highly susceptible to environmental contaminants. The liner can be damaged easily if dirt is present from the start.

Incorrect Installation

Proper installation is paramount. Using a hammer or applying force to the wrong part of the bearing can deform the backing or damage the liner, creating an uneven contact surface that will wear out and develop clearance almost immediately.

Misapplication

These bearings excel in high-load, low-speed oscillating applications. Using them in high-speed rotational applications can generate excessive heat, causing the PTFE liner to degrade and fail.

How to Apply This to Your Project

Your approach should depend on whether you are designing a new system, installing components, or performing maintenance.

- If your primary focus is system design: Ensure the housing bore and shaft meet the precise tolerances required to achieve the correct interference fit or preload for the bearing.

- If your primary focus is installation: Always use a proper arbor press with correctly sized mandrels that apply force only to the rigid outer shell, ensuring the bearing goes in straight and true.

- If your primary focus is maintenance and inspection: Periodically check for any perceptible play or "rocking" motion in the joint. Any detectable looseness is a direct indicator that the wear process has begun and replacement is imminent.

Ultimately, viewing a PTFE-lined bearing as a precision system that relies on intimate contact is the key to its successful application and longevity.

Summary Table:

| Stage of Failure | Key Consequence |

|---|---|

| Initial Clearance | Loss of intimate contact needed to maintain the PTFE transfer film. |

| Transfer Film Breakdown | Self-lubricating PTFE-on-PTFE system fails, increasing friction. |

| Abrasive Wear | Hard ball grinds directly against the liner, accelerating degradation. |

| Contaminant Ingress | Dirt and grit enter the gap, embedding in the liner and accelerating wear. |

| Total Failure | Bearing loses precision and load capacity, requiring immediate replacement. |

Ensure your application's reliability with precision PTFE components from KINTEK.

When PTFE-lined bearing failure is not an option, you need components manufactured to exacting standards. KINTEK specializes in high-performance PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring the perfect fit and performance your critical systems demand.

Don't let component failure halt your operations. Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support