When selecting a PTFE lip seal, the primary factors to consider are the application's operating temperature, shaft surface speed, system pressure, and the chemical media being sealed. These core parameters dictate the required seal material, profile, and energizer design to ensure reliable performance and a long service life.

The challenge isn't just knowing the operating conditions, but understanding how they interact. A successful selection requires matching a specific seal design and PTFE compound to the complete environmental picture, not just a single demanding factor.

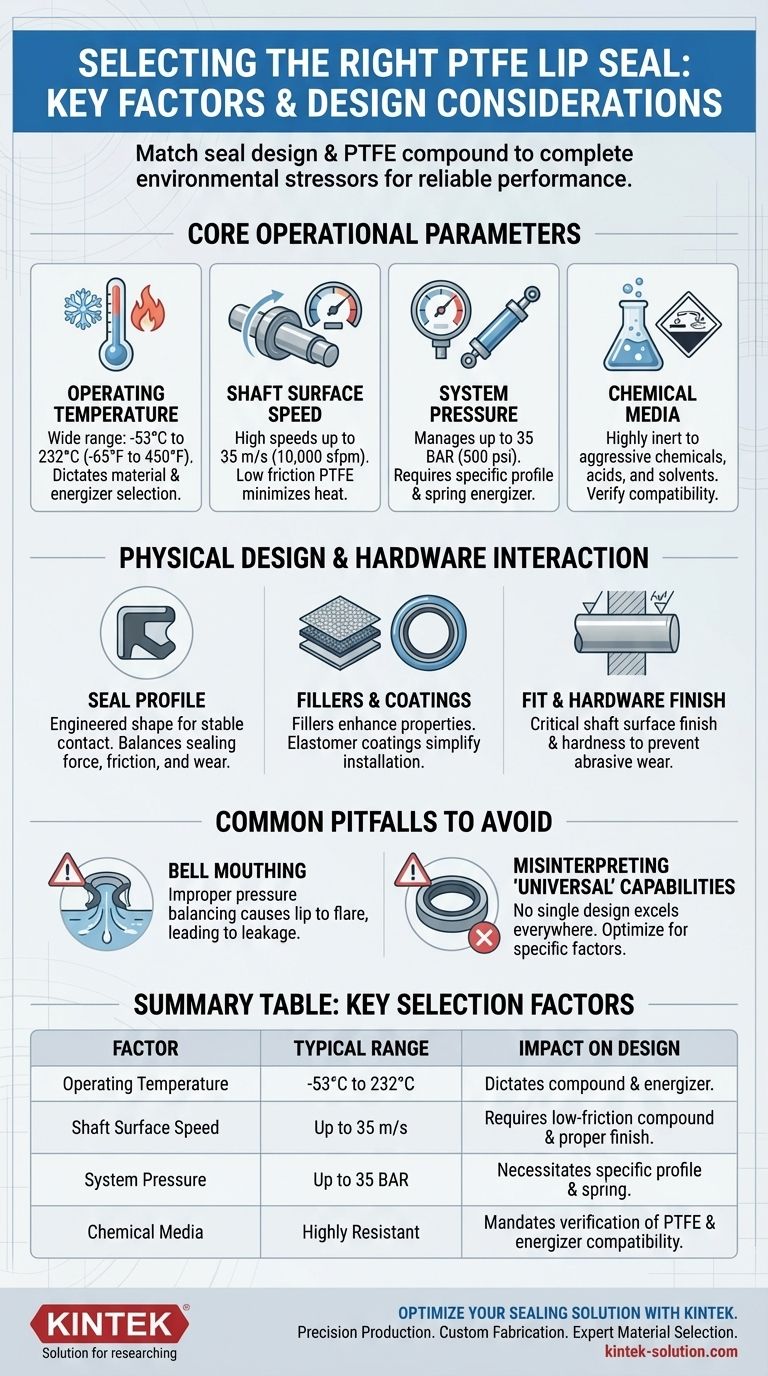

Core Operational Parameters

The performance of a PTFE lip seal is directly tied to the four key environmental stressors of any sealing application. A failure to account for any one of these can lead to premature failure.

The Influence of Temperature

PTFE is known for its exceptionally wide operating temperature range, typically cited from -53°C to 232°C (-65°F to 450°F).

However, this full range is not achievable by a single seal configuration. The specific PTFE compound, including any fillers, and the energizer material (if used) must be chosen based on the specific temperatures your application will experience.

Accommodating Shaft Surface Velocity

A key advantage of PTFE is its low-friction characteristic, which allows for very high shaft speeds, often exceeding 35 m/s (or 10,000 sfpm).

Unlike traditional elastomeric seals that can overheat and fail at high speeds, PTFE's lubricity minimizes frictional heat generation, extending seal life in demanding rotary applications.

Managing System Pressure

Standard PTFE lip seals can effectively manage pressures in excess of 35 BAR (500 psi).

The seal's profile and the presence of a spring energizer are critical for maintaining a consistent sealing force against the shaft under pressure, preventing leaks without causing excessive wear.

Ensuring Media Compatibility

PTFE is almost universally inert, making it an ideal choice for sealing aggressive chemicals, acids, solvents, and a wide range of industrial lubricants.

This chemical resistance also allows PTFE seals to perform reliably in applications with dry or abrasive media, where other materials would quickly degrade.

Physical Design and Hardware Interaction

Beyond the core operational parameters, the physical design of the seal and its interaction with the hardware are just as critical for a successful outcome.

Seal Profile and Configuration

The shape of the sealing lip has a profound impact on performance. Designs must be carefully engineered to maintain a stable contact point with the shaft under all conditions.

Custom profiles are often developed to meet unique application demands, balancing sealing force with friction and wear characteristics.

The Role of Fillers and Coatings

The base PTFE resin is often blended with fillers like glass, carbon, or graphite to enhance specific properties such as wear resistance, thermal conductivity, and creep resistance.

Additionally, some PTFE seals feature an elastomer coating on their outer diameter. This simplifies installation and ensures a static seal within the housing bore.

Dimensional Fit and Hardware Finish

The seal must be dimensionally matched to the shaft and bore. However, the condition of the shaft surface is equally important.

For optimal performance, especially at high speeds, the shaft requires a specific surface finish and hardness to prevent abrasive wear on the soft PTFE lip.

Common Pitfalls to Avoid

Even the best seal material can fail if its limitations or the subtleties of its application are misunderstood. Awareness of common failure modes is key to a robust design.

The Risk of "Bell Mouthing"

In certain wide-contact seal designs, improper pressure balancing can cause the lip to flare away from the shaft, a phenomenon known as bell mouthing.

This creates a wedge that can actively pump fluid past the seal, leading to high leakage rates. This is purely a design flaw and must be engineered out of the seal profile.

Misinterpreting "Universal" Capabilities

While PTFE as a material has a broad range of capabilities, no single seal design excels in all areas simultaneously.

A seal optimized for high pressure may have higher friction, making it less suitable for a high-speed, low-pressure application. You must select a design optimized for your specific combination of factors.

Making the Right Choice for Your Application

Ultimately, your selection should be driven by the most critical demand of your system.

- If your primary focus is high-speed rotation: Prioritize a low-friction PTFE compound and ensure your shaft has the appropriate hardness and surface finish.

- If your primary focus is sealing aggressive chemicals: Select a PTFE compound verified for compatibility with your specific media, paying attention to both the seal and any energizer materials.

- If your primary focus is high pressure: Choose a spring-energized or pressure-balanced seal profile designed to prevent extrusion and maintain a consistent sealing force.

- If your primary focus is extreme temperatures: Verify that the chosen PTFE grade and energizer material are rated for the full operational temperature range you expect.

Choosing the right PTFE lip seal is a process of aligning the material's strengths with your application's specific challenges.

Summary Table:

| Key Selection Factor | Typical Range for PTFE Lip Seals | Impact on Seal Design |

|---|---|---|

| Operating Temperature | -53°C to 232°C (-65°F to 450°F) | Dictates PTFE compound and energizer material selection. |

| Shaft Surface Speed | Up to 35 m/s (10,000 sfpm) | Requires low-friction PTFE compounds and proper shaft finish. |

| System Pressure | Up to 35 BAR (500 psi) | Necessitates specific profiles and spring energizers to prevent extrusion. |

| Chemical Media | Highly resistant to aggressive chemicals, acids, and solvents. | Mandates verification of PTFE grade and energizer compatibility. |

Optimize Your Sealing Solution with KINTEK

Selecting the right PTFE lip seal is critical for the reliability of your equipment in the semiconductor, medical, laboratory, and industrial sectors. KINTEK specializes in manufacturing high-performance PTFE components, including custom lip seals, to meet your exact operational demands.

We offer:

- Precision Production: Ensuring dimensional accuracy for a perfect fit and function.

- Custom Fabrication: From initial prototypes to high-volume production runs.

- Expert Material Selection: Guiding you to the ideal PTFE compound and seal design for your specific temperature, speed, pressure, and chemical requirements.

Let our expertise ensure your application's success. Contact KINTEK today to discuss your project and receive a custom solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the two production methods for PTFE sliding bearing pads? A Guide to Manufacturing Choices

- What temperature range can expanded PTFE gaskets withstand? From Cryogenic -200°C to High-Temp 260°C

- Why are PTFE-lined valves considered low maintenance? Achieve Maximum Uptime & Lower Costs

- What are the primary applications of PTFE V-rings? Seal Moving Parts in Demanding Systems

- What are the benefits of CNC machining for custom PTFE applications? Achieve Unmatched Precision & Performance

- What are the key benefits of using PTFE for piston rings in oil-free compressors? Achieve Clean, Efficient Compression

- What types of media can PTFE lined ball valves handle? Handle Corrosive Fluids Safely

- What industries commonly use Teflon gland packing and why? Unlock Superior Sealing Performance