At their core, PTFE V-rings are specialized sealing components designed for demanding dynamic applications. They are primarily used to create a reliable seal on moving parts such as hydraulic cylinder plungers, piston rods, presses, valve spindles, and controllers, especially in critical hydraulic and pneumatic systems.

The true value of PTFE V-rings lies not just in their shape, but in the material itself. They are the preferred solution for sealing systems that move, especially under high speeds or in contact with aggressive chemicals, where low friction and material stability are paramount.

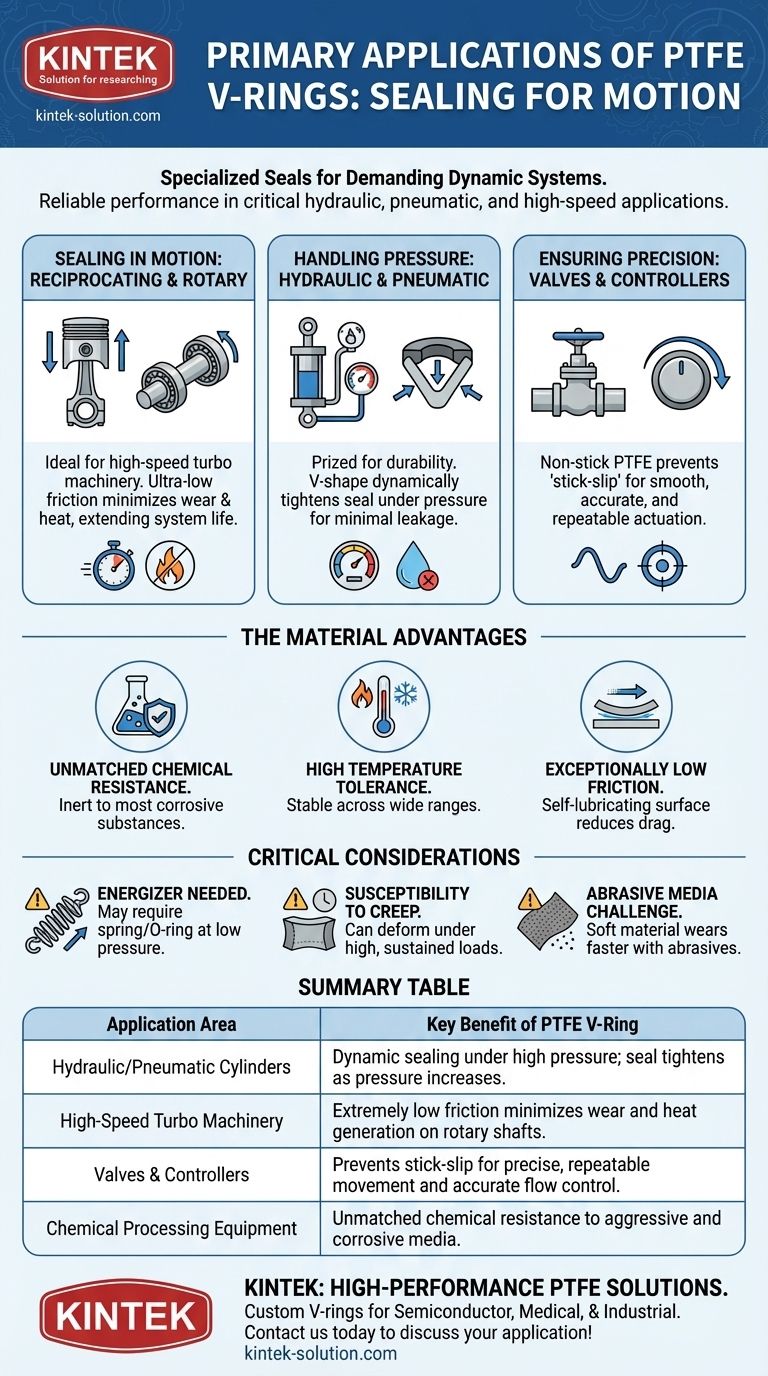

Why PTFE V-Rings Excel in Dynamic Sealing

The applications for PTFE V-rings are defined by motion. Unlike static O-rings that seal stationary connections, V-rings are engineered to perform reliably on parts that are constantly moving, often under significant pressure.

Sealing in Motion: Reciprocating and Rotary Systems

PTFE V-rings are a go-to solution for sealing reciprocating pistons and rotary shafts. This includes applications in high-speed turbo machinery and other equipment where parts slide or spin continuously.

The material's exceptionally low coefficient of friction is the key advantage here. It minimizes drag and heat generation, which reduces wear on both the seal and the moving component, extending the operational life of the entire system.

Handling Pressure: Hydraulic and Pneumatic Systems

In critical hydraulic and pneumatic systems, such as cylinder plungers and industrial presses, maintaining a seal under high pressure is essential.

PTFE V-rings are prized for their durability and ability to handle these forces. Their V-shape allows them to respond to pressure, tightening the seal dynamically as system pressure increases, ensuring minimal leakage.

Ensuring Precision: Valves and Controllers

Applications like valve spindles and controllers require precise, repeatable movement without sticking.

The non-stick properties of PTFE prevent the "stick-slip" phenomenon common with other materials, allowing for smooth actuation and accurate control over fluid or gas flow.

The Material Properties Driving Performance

The choice to use a PTFE V-ring is a choice for a specific set of material advantages. These inherent properties make PTFE uniquely suited for its primary applications.

Unmatched Chemical Resistance

PTFE is virtually inert to most industrial chemicals and corrosive substances. This makes V-rings made from it essential for equipment in the chemical processing industry and other environments handling reactive fluids.

High Temperature Tolerance

These seals maintain their integrity and performance across a wide temperature range. This stability is critical in systems where friction or the process media generates significant heat.

Exceptionally Low Friction

As a lubricant itself, PTFE provides a smooth, low-friction sealing surface. This not only reduces wear but also lowers the energy required to operate the machinery.

Common Pitfalls and Considerations

While powerful, PTFE V-rings are not a universal solution. Understanding their limitations is key to successful implementation.

The Need for an Energizer

Pure PTFE is not a highly elastic material like rubber. In low-pressure situations, a V-ring may require an "energizer" (often a metal spring or elastomer O-ring) to provide the initial force needed to maintain a tight seal.

Susceptibility to Creep

Under high, sustained loads, PTFE can be prone to "creep" or cold flow, meaning it can slowly deform over time. Proper gland design and the use of support rings are critical to mitigate this effect in high-pressure applications.

Abrasive Media Can Be a Challenge

While PTFE handles friction well, it is a relatively soft material. In systems with highly abrasive media (like slurries), it can wear more quickly than harder seal materials.

Making the Right Choice for Your Application

Selecting the right seal requires matching its properties to your operational goal.

- If your primary focus is dynamic sealing with aggressive chemicals: PTFE V-rings are an ideal choice due to their unparalleled chemical inertness.

- If your primary focus is high-speed or continuous motion: The extremely low friction of PTFE minimizes wear and heat generation, ensuring system longevity and efficiency.

- If your primary focus is high-pressure hydraulics: Ensure the PTFE V-ring set is correctly designed, often with support or backup rings, to handle the force and prevent extrusion.

By understanding the unique properties of PTFE, you can confidently deploy V-rings to ensure reliability in your most demanding sealing applications.

Summary Table:

| Application Area | Key Benefit of PTFE V-Ring |

|---|---|

| Hydraulic/Pneumatic Cylinders | Dynamic sealing under high pressure; seal tightens as pressure increases. |

| High-Speed Turbo Machinery | Extremely low friction minimizes wear and heat generation on rotary shafts. |

| Valves & Controllers | Prevents stick-slip for precise, repeatable movement and accurate flow control. |

| Chemical Processing Equipment | Unmatched chemical resistance to aggressive and corrosive media. |

Need a reliable seal for moving parts? KINTEK specializes in manufacturing high-performance PTFE components, including custom V-rings for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your seals handle high speeds, pressure, and aggressive chemicals, extending the life of your equipment. From prototypes to high-volume orders, we deliver solutions tailored to your exact needs. Contact us today to discuss your application!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support