The most common industries using Teflon gland packing are Chemical Processing, Food & Pharmaceuticals, and Oil & Gas. These sectors rely on this material for its unparalleled chemical resistance, non-reactivity, and ability to perform under extreme temperatures and pressures, ensuring both safety and product purity in demanding operational environments.

The core reason Teflon (PTFE) gland packing is so widely adopted is not just one superior feature, but its unique combination of properties. It solves the critical industrial challenge of creating a reliable, long-lasting seal in environments where chemical attack, contamination, or extreme conditions would cause other materials to fail.

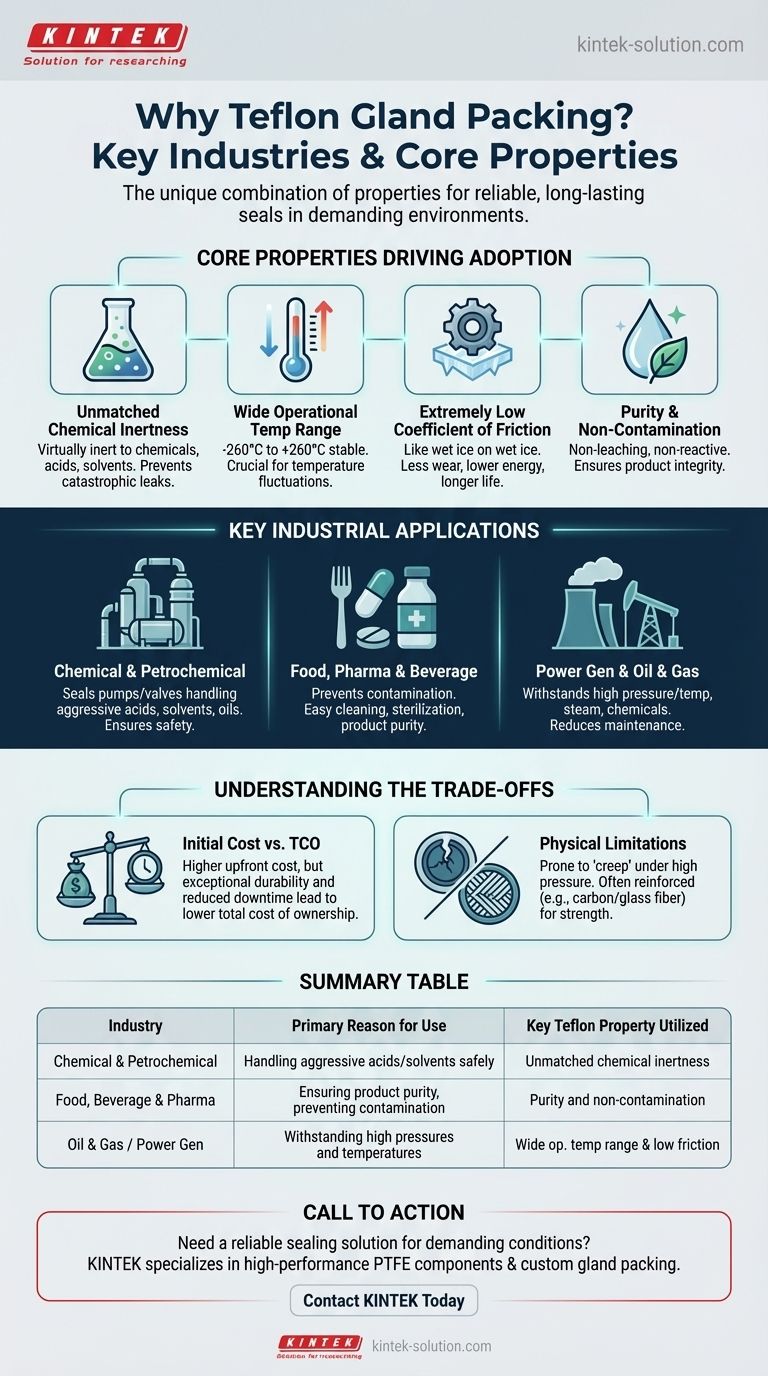

The Core Properties Driving Adoption

To understand why Teflon packing is a default choice in so many critical applications, we must first look at its fundamental material characteristics. Each property solves a specific, and often costly, industrial problem.

Unmatched Chemical Inertness

Teflon is virtually inert to almost all industrial chemicals, acids, and solvents. This means it will not degrade, swell, or weaken when exposed to corrosive or aggressive media.

This property is non-negotiable in chemical and petrochemical plants where leakage of a hazardous substance could be catastrophic.

Wide Operational Temperature Range

Teflon gland packing maintains its integrity and sealing capability across a broad spectrum of temperatures, from cryogenic lows to highs of around 260°C (500°F).

This stability is crucial in power plants, refineries, and chemical reactors where processes involve significant temperature fluctuations.

Extremely Low Coefficient of Friction

Often compared to wet ice on wet ice, Teflon has one of the lowest friction coefficients of any solid material.

In rotating equipment like pumps and mixers, this translates directly to less wear on shafts and sleeves, reduced energy consumption, and longer service life for the machinery.

Purity and Non-Contamination

Because Teflon is chemically inert, it does not leach substances or react with the materials it contacts. This ensures the purity of the product being processed.

This is the primary reason it is specified for applications in food, beverage, and pharmaceutical manufacturing, where any form of contamination is unacceptable.

A Closer Look at Key Industrial Applications

These core properties make Teflon packing the ideal solution for sealing pumps, valves, and other rotating equipment in several key sectors.

In Chemical and Petrochemical Processing

This is the largest user of Teflon packing. It is used to seal pumps and valves handling everything from aggressive acids and solvents to lacquers and mineral oils, preventing dangerous leaks and ensuring process safety.

In Food, Beverage, and Pharmaceuticals

Here, the focus is on preventing contamination. Teflon's non-reactive and non-stick surface ensures that the product remains pure and that the equipment can be easily cleaned and sterilized.

In Power Generation and Pulp & Paper

These industries require seals that can withstand high pressures, high temperatures, and various process fluids like steam, water, and mild chemicals. Teflon packing provides a reliable seal that reduces maintenance needs in these demanding 24/7 operations.

Understanding the Trade-offs

While highly effective, Teflon packing is not a universal solution. Acknowledging its limitations is key to making an informed decision.

Initial Cost vs. Total Cost of Ownership

Teflon gland packing often has a higher upfront cost compared to conventional materials like graphite or aramid fiber packings.

However, its exceptional durability, reduced need for maintenance, and ability to prevent costly equipment wear and production downtime typically result in a significantly lower total cost of ownership over the long term.

Physical Limitations

While chemically robust, standard PTFE can be prone to "creep" or cold flow under high mechanical pressure, which can affect sealing integrity over time. It is also less resistant to high-energy radiation and abrasive media than some other packing materials.

For this reason, it is often reinforced with other materials like carbon or glass fibers to enhance its mechanical strength for specific high-pressure or slurry applications.

Making the Right Choice for Your Goal

Selecting the right packing material depends entirely on the primary challenge you need to solve.

- If your primary focus is handling aggressive chemicals: Teflon's near-total chemical inertness makes it the safest and most reliable choice.

- If your primary focus is product purity (food, pharma): Its non-contaminating, non-reactive nature is essential for regulatory compliance and product quality.

- If your primary focus is equipment longevity and reduced maintenance: The low-friction property is key to minimizing wear on shafts and extending service intervals.

Ultimately, Teflon gland packing is chosen when the cost of failure—whether through leakage, contamination, or downtime—is far greater than the investment in a premium sealing solution.

Summary Table:

| Industry | Primary Reason for Use | Key Teflon Property Utilized |

|---|---|---|

| Chemical & Petrochemical | Handling aggressive acids/solvents safely | Unmatched chemical inertness |

| Food, Beverage & Pharmaceutical | Ensuring product purity and preventing contamination | Purity and non-contamination |

| Oil & Gas / Power Generation | Withstanding high pressures and temperatures | Wide operational temperature range & low friction |

Need a reliable sealing solution for demanding conditions? KINTEK specializes in manufacturing high-performance PTFE components, including custom gland packing. Our precision production ensures seals that deliver superior chemical resistance, maintain product purity, and extend equipment life—from prototypes to high-volume orders for the semiconductor, medical, laboratory, and industrial sectors.

Contact KINTEK today to discuss how our PTFE expertise can solve your specific sealing challenge!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability