To put it directly, PTFE gaskets are renowned for their ability to withstand a remarkably wide range of extreme environmental conditions. They offer exceptional resistance to high and low temperatures, near-universal chemical inertness against acids and alkalis, and tolerance for significant pressure, making them a default choice for many harsh industrial applications.

The core takeaway is that while PTFE offers elite chemical and thermal resistance, its primary limitations are mechanical. For a successful and reliable seal, you must account for its rigidity and tendency to deform under pressure over time.

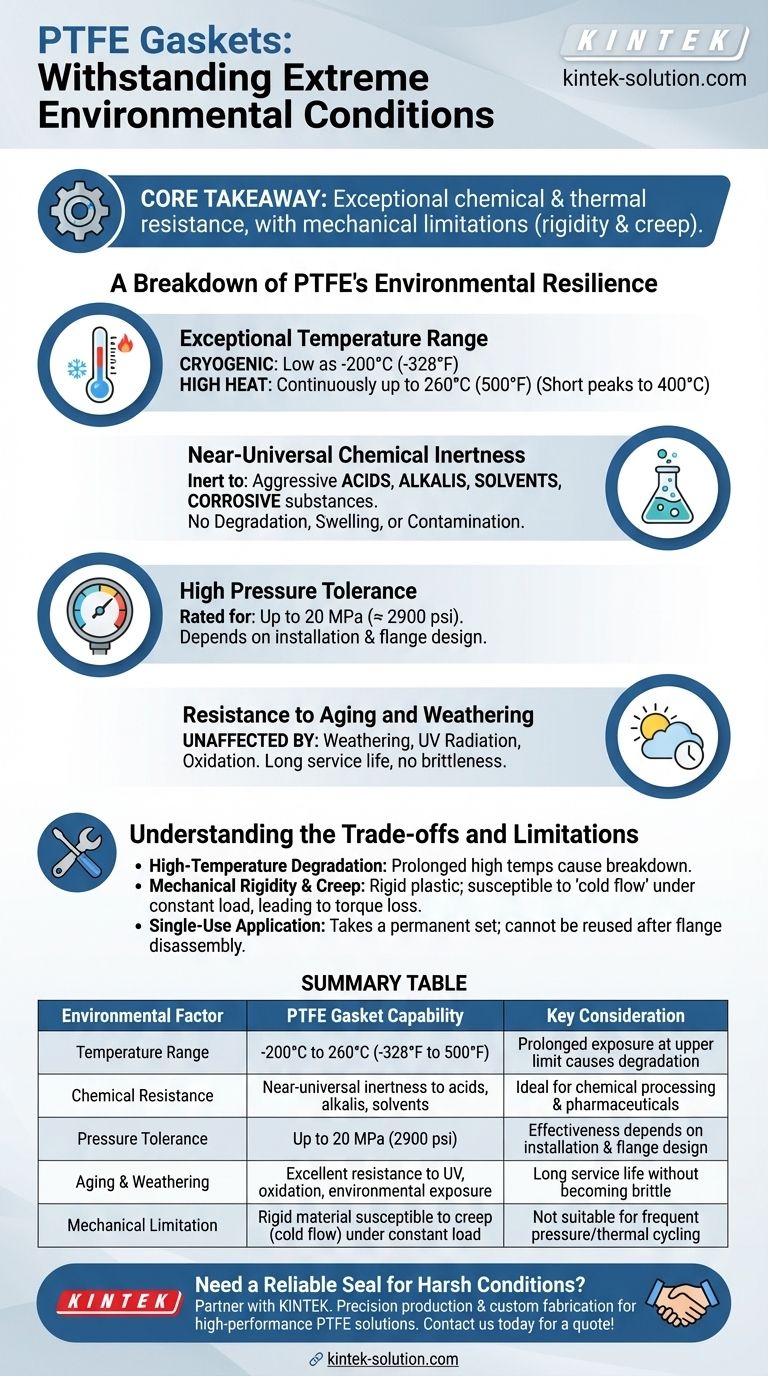

A Breakdown of PTFE's Environmental Resilience

To determine if a PTFE gasket is suitable for your environment, you must understand its specific capabilities across several key metrics.

Exceptional Temperature Range

PTFE performs reliably in both cryogenic and high-heat conditions. It maintains its integrity and sealing properties in temperatures as low as -200°C (-328°F).

On the high end, it can continuously withstand temperatures up to 260°C (500°F). While some specialized variants may tolerate brief peaks up to 400°C, the 260°C mark is the standard and safe upper limit for sustained use.

Near-Universal Chemical Inertness

This is arguably PTFE's most significant advantage. It is chemically inert to almost all industrial chemicals, including aggressive acids, alkalis, solvents, and other corrosive substances.

This property ensures the gasket will not degrade, swell, or contaminate the process medium, which is critical in industries like chemical processing, pharmaceuticals, and food and beverage.

High Pressure Tolerance

PTFE gaskets are capable of sealing significant internal pressures, often rated for applications up to 20 MPa (approximately 2900 psi).

This makes them suitable for many standard piping and equipment flange connections, though their effectiveness under pressure is closely tied to proper installation and flange design.

Resistance to Aging and Weathering

Unlike many elastomers, PTFE is virtually unaffected by weathering, UV radiation, and oxidation. The material does not become brittle or degrade over time due to environmental exposure, ensuring a long service life.

Understanding the Trade-offs and Limitations

No material is perfect. To prevent gasket failure, it is crucial to understand PTFE's limitations, which are primarily mechanical rather than environmental.

The Risk of High-Temperature Degradation

While highly resistant to heat, PTFE can break down if exposed to prolonged temperatures at the very top of its service range. This degradation can be more pronounced in applications covering large, hot surface areas.

Mechanical Rigidity and Creep

PTFE is a rigid plastic, not a flexible rubber. It requires a high and consistent compressive load from the flange bolts to create an effective seal.

More importantly, PTFE is susceptible to creep (or "cold flow"), where the material slowly deforms over time while under a constant load. This can lead to a loss of bolt torque and, eventually, a leak if not accounted for in the system design.

Single-Use Application

Once a PTFE gasket is compressed in a flange, it takes a permanent set. It cannot be reused after the flange is disassembled, as it will not provide a reliable seal a second time.

Making the Right Choice for Your Application

Use these points to determine if PTFE is the optimal choice for your specific operational goal.

- If your primary focus is chemical resistance: PTFE is an unparalleled choice for sealing against nearly all aggressive media.

- If your application involves extreme temperatures: PTFE is highly effective, but be mindful of its upper continuous limit (around 260°C) and potential for creep under load.

- If you have fluctuating pressures or thermal cycling: Be cautious. The rigidity and creep of solid PTFE may require specialized flange design or the use of an alternative like a PTFE envelope gasket to maintain a reliable seal.

By understanding both its exceptional resilience and its mechanical limitations, you can confidently specify PTFE gaskets for the harshest industrial environments.

Summary Table:

| Environmental Factor | PTFE Gasket Capability | Key Consideration |

|---|---|---|

| Temperature Range | -200°C to 260°C (-328°F to 500°F) | Prolonged exposure at upper limit can cause degradation |

| Chemical Resistance | Near-universal inertness to acids, alkalis, solvents | Ideal for chemical processing and pharmaceuticals |

| Pressure Tolerance | Up to 20 MPa (2900 psi) | Effectiveness depends on proper installation and flange design |

| Aging & Weathering | Excellent resistance to UV, oxidation, and environmental exposure | Long service life without becoming brittle |

| Mechanical Limitation | Rigid material susceptible to creep (cold flow) under constant load | Not suitable for applications with frequent pressure/thermal cycling |

Need a Reliable Seal for Harsh Conditions? Partner with KINTEK.

PTFE gaskets excel in extreme environments, but their success depends on precision manufacturing and proper material selection. At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring your PTFE gaskets are engineered to withstand your specific operational challenges.

Contact us today to discuss your application requirements and get a quote for durable, chemically inert PTFE solutions!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining