The most common household item coated with Polytetrafluoroethylene (PTFE) is the nonstick frying pan. This material, widely known by its brand name Teflon, is what gives modern cookware its characteristic slippery, easy-to-clean surface. Its unique properties prevent food from sticking during the cooking process.

PTFE's value comes from its extremely low friction, making it the ideal material for creating nonstick surfaces. However, its application to cookware is a precise industrial process designed to bond a stable coating to a metal base.

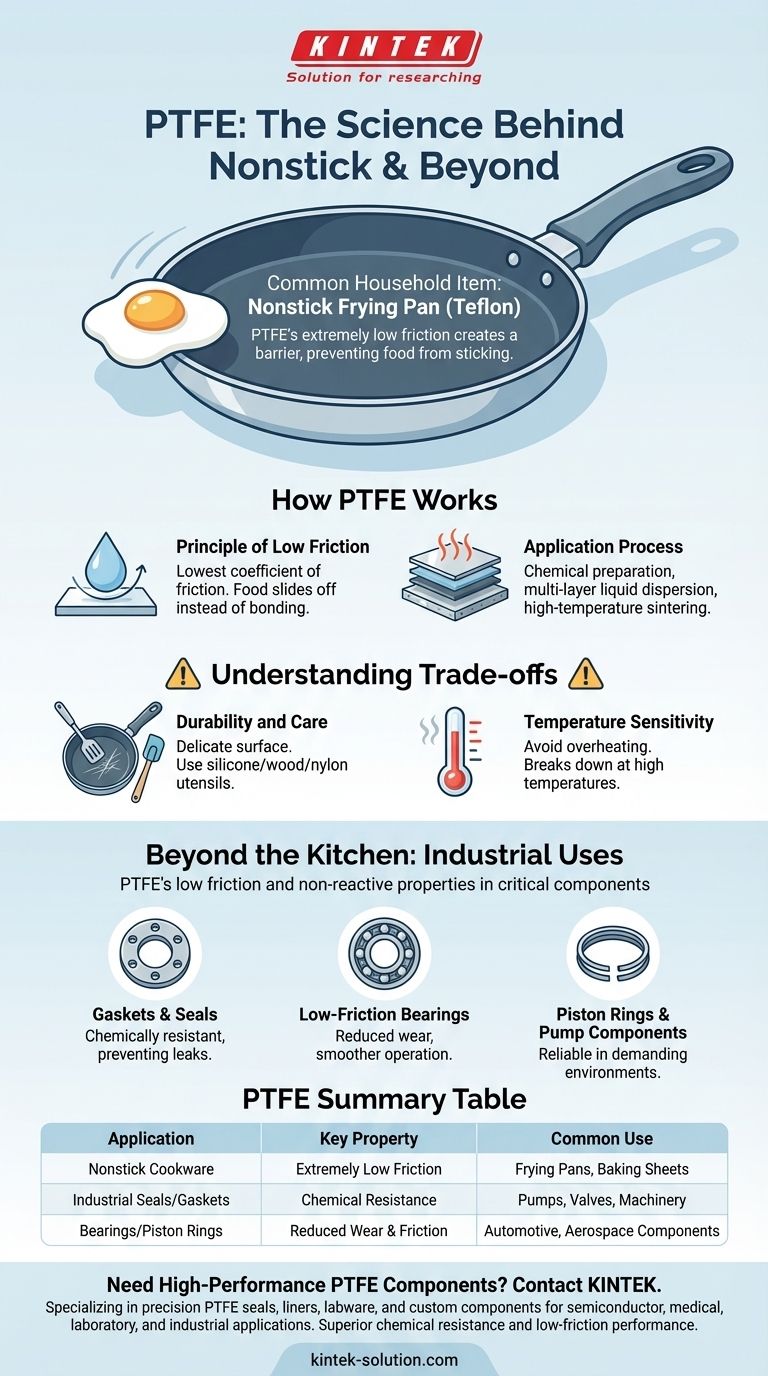

How PTFE Creates a Nonstick Surface

The core function of a PTFE coating is to create a barrier between your food and the metal of the pan. This is possible due to the material's unique chemical structure, which leads to some powerful properties.

The Principle of Low Friction

PTFE has one of the lowest coefficients of friction of any known solid. This means very few things will stick to it, a property that is highly desirable in a cooking environment. Food simply slides off the surface instead of bonding to it when heated.

The Application Process

Creating a durable nonstick pan isn't as simple as painting on a layer of PTFE. The metal surface, typically aluminum or stainless steel, must first be chemically prepared, often through a process called etching.

A liquid dispersion of PTFE is then applied in multiple layers. Finally, the cookware is heated to a high temperature in a process called sintering, which bakes the coating, bonds it securely to the metal, and creates the durable, non-stick finish.

Understanding the Trade-offs

While highly effective, PTFE coatings have practical limitations that are important to understand for proper use and longevity.

Durability and Care

The PTFE coating is the most delicate part of the pan. Using metal utensils can easily scratch or chip the surface, compromising its nonstick properties. It's for this reason that silicone, wood, or nylon utensils are recommended.

Temperature Sensitivity

While the coating is stable for most cooking applications, overheating nonstick pans can cause the PTFE to break down. This reinforces the need to follow manufacturer guidelines and avoid prolonged use on high heat, especially when the pan is empty.

Beyond the Kitchen: Other PTFE Uses

PTFE's usefulness extends far beyond cookware. Its low-friction and non-reactive properties make it a critical component in many industrial and mechanical applications.

Key Industrial Components

You will find PTFE in demanding environments where reducing friction and preventing chemical reactions are critical. Common examples include industrial gaskets and seals, low-friction bearings, piston rings, and chemically resistant pump components.

Making the Right Choice for Your Goal

- If your primary focus is cooking convenience: PTFE-coated nonstick pans provide an unmatched, easy-release surface that simplifies both cooking and cleanup.

- If your primary focus is longevity: Preserve the coating by avoiding metal utensils, harsh scouring pads, and excessively high heat.

- If your primary focus is industrial performance: PTFE is a reliable material for creating durable, low-friction seals, bearings, and other mechanical parts.

Understanding the role of PTFE allows you to leverage its benefits, whether you are in the kitchen or a more industrial setting.

Summary Table:

| PTFE Application | Key Property | Common Use |

|---|---|---|

| Nonstick Cookware | Extremely Low Friction | Frying Pans, Baking Sheets |

| Industrial Seals/Gaskets | Chemical Resistance | Pumps, Valves, Machinery |

| Bearings/Piston Rings | Reduced Wear & Friction | Automotive, Aerospace Components |

Need high-performance PTFE components for your project? KINTEK specializes in manufacturing precision PTFE seals, liners, labware, and custom components for semiconductor, medical, laboratory, and industrial applications. We deliver superior chemical resistance and low-friction performance from prototypes to high-volume orders. Contact our experts today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications