The primary challenges in machining PTFE stem from its unique combination of physical properties. Its low strength, softness, and extremely high coefficient of thermal expansion make it prone to deformation under clamping pressure and heat, complicating the process of holding tight dimensional tolerances.

The core challenge of machining Polytetrafluoroethylene (PTFE) is a paradox: while the material is soft and easy to cut, its instability makes it difficult to cut accurately. Success requires a strategy that accommodates the material's inherent properties, not one that fights against them.

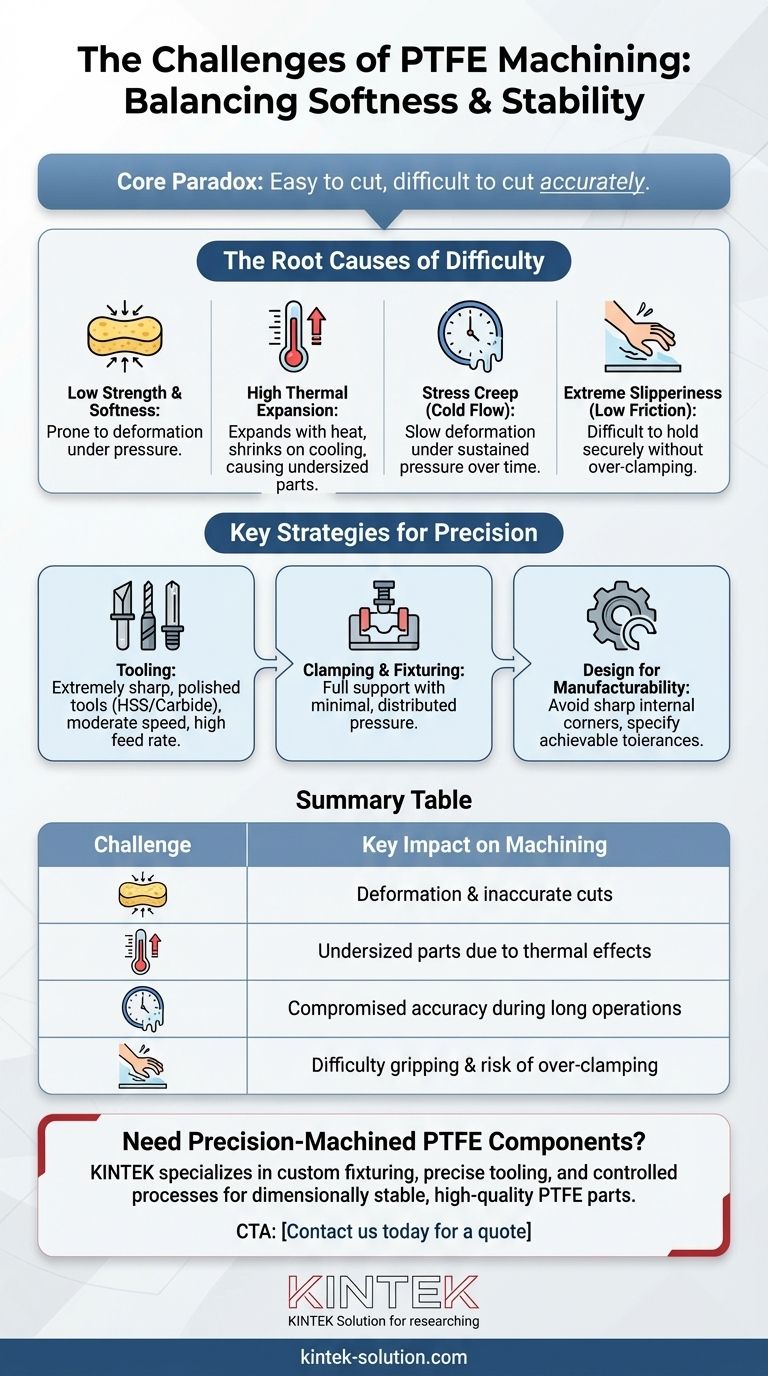

The Root Causes of Machining Difficulty

PTFE's desirable characteristics—such as its chemical inertness and low friction—are directly linked to the properties that make it a challenge to machine with precision. Understanding these root causes is the first step toward overcoming them.

Low Strength and Softness

PTFE is a soft polymer with low tensile strength. While this means tools can remove material with little effort, it also means the workpiece can easily be compressed or deformed.

Excessive pressure from clamping fixtures or even the cutting tool itself can distort the part. This distortion leads to inaccurate cuts that only become apparent after the pressure is released and the material returns to its natural state.

High Coefficient of Thermal Expansion

PTFE expands and contracts with temperature changes far more than most metals or other plastics. The friction from the cutting process generates localized heat, causing the material to expand.

If you machine a heated, expanded part to a specific dimension, it will shrink as it cools, resulting in a final component that is undersized and out of tolerance. Managing heat is therefore critical for dimensional accuracy.

Stress Creep (Cold Flow)

Under sustained pressure, even at room temperature, PTFE has a tendency to "creep" or slowly deform over time.

This means that a part clamped in a fixture for an extended period can gradually change shape, compromising the accuracy of the machining operation. This is especially relevant for longer or more complex machining cycles.

Extreme Slipperiness (Low Friction)

PTFE's famously low coefficient of friction makes it difficult to grip securely.

Machinists face a constant battle between using enough clamping force to prevent the part from moving during cutting and using too little force to avoid deforming the soft material. This delicate balance is key to a successful outcome.

Key Strategies for Precision Machining

To counter these challenges, machinists must adopt specific techniques tailored to PTFE's unique behavior. The goal is always to minimize stress, heat, and movement.

Tooling and Cutting Parameters

The right tools and settings are non-negotiable.

Use extremely sharp and polished cutting tools, preferably High-Speed Steel (HSS) or carbide. A sharp edge cleanly shears the material rather than pushing it, which reduces tool pressure and heat generation.

Employ moderate cutting speeds and high feed rates. This approach removes material quickly, transferring heat into the chip and away from the workpiece before it can cause significant thermal expansion.

Clamping and Fixturing

How you hold the workpiece is arguably the most critical factor.

Use fixtures that provide full support with minimal clamping pressure. Instead of a standard vise that concentrates pressure on two points, consider custom jigs, collets, or soft jaws that distribute the load over a larger surface area. The goal is to secure the part without squeezing it.

Design for Manufacturability

The most effective strategy often begins at the design stage.

Whenever possible, design parts with PTFE's properties in mind. Avoid unnecessarily sharp internal corners, which can create stress points, and specify tolerances that are achievable without extreme measures. Simplifying complex features can dramatically reduce machining difficulty and cost.

Understanding the Trade-offs

Working with PTFE requires acknowledging its limitations and balancing ideal outcomes with practical realities.

The Tolerance vs. Cost Dilemma

Achieving extremely tight tolerances on a PTFE component is possible, but it is a specialized skill. It requires experienced operators, a controlled environment, and often results in slower cycle times and higher scrap rates. You must determine if the application truly justifies the added expense.

The Risk of Over-Clamping

The natural instinct to secure a slippery part is to tighten the fixture. With PTFE, this is a critical mistake. Over-clamping induces stress and deformation, guaranteeing an inaccurate part once it is released. It is better to have a part move slightly and recut it than to finish a deformed component.

Heat as the Unseen Enemy

Every aspect of the machining process must be viewed through the lens of heat management. Dull tools, excessive spindle speed, or aggressive cuts all generate heat that will directly compromise the final dimensions of your part through thermal expansion.

Making the Right Choice for Your Goal

Your approach should be tailored to the specific requirements of your component.

- If your primary focus is high-volume production: Design the part with generous tolerances and simple geometry to enable faster, more reliable machining.

- If your primary focus is a critical, tight-tolerance component: Invest in custom fixturing, climate control, and work with a machine shop that has proven expertise in machining soft, unstable polymers.

- If your primary focus is prototyping: Use the sharpest tools available and start with conservative speeds, being prepared to iterate as you learn how the material reacts to your specific design.

By respecting its unique physical properties, you can successfully machine PTFE to meet the needs of your most demanding applications.

Summary Table:

| Challenge | Key Impact on Machining |

|---|---|

| Low Strength & Softness | Prone to deformation under clamping/cutting pressure, leading to inaccurate cuts. |

| High Thermal Expansion | Heat from cutting causes expansion; parts shrink upon cooling, resulting in undersized dimensions. |

| Stress Creep (Cold Flow) | Deforms under sustained pressure over time, compromising accuracy during long operations. |

| Extreme Slipperiness | Difficult to grip securely without deforming the soft material, requiring a delicate balance. |

Need Precision-Machined PTFE Components?

At KINTEK, we specialize in overcoming the unique challenges of machining PTFE. Our expertise in custom fixturing, precise tooling, and controlled processes ensures your seals, liners, and labware are manufactured to exact specifications, from prototypes to high-volume orders.

We deliver dimensionally stable, high-quality PTFE parts for the semiconductor, medical, and industrial sectors.

Contact us today for a quote and let our precision production expertise work for you.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments