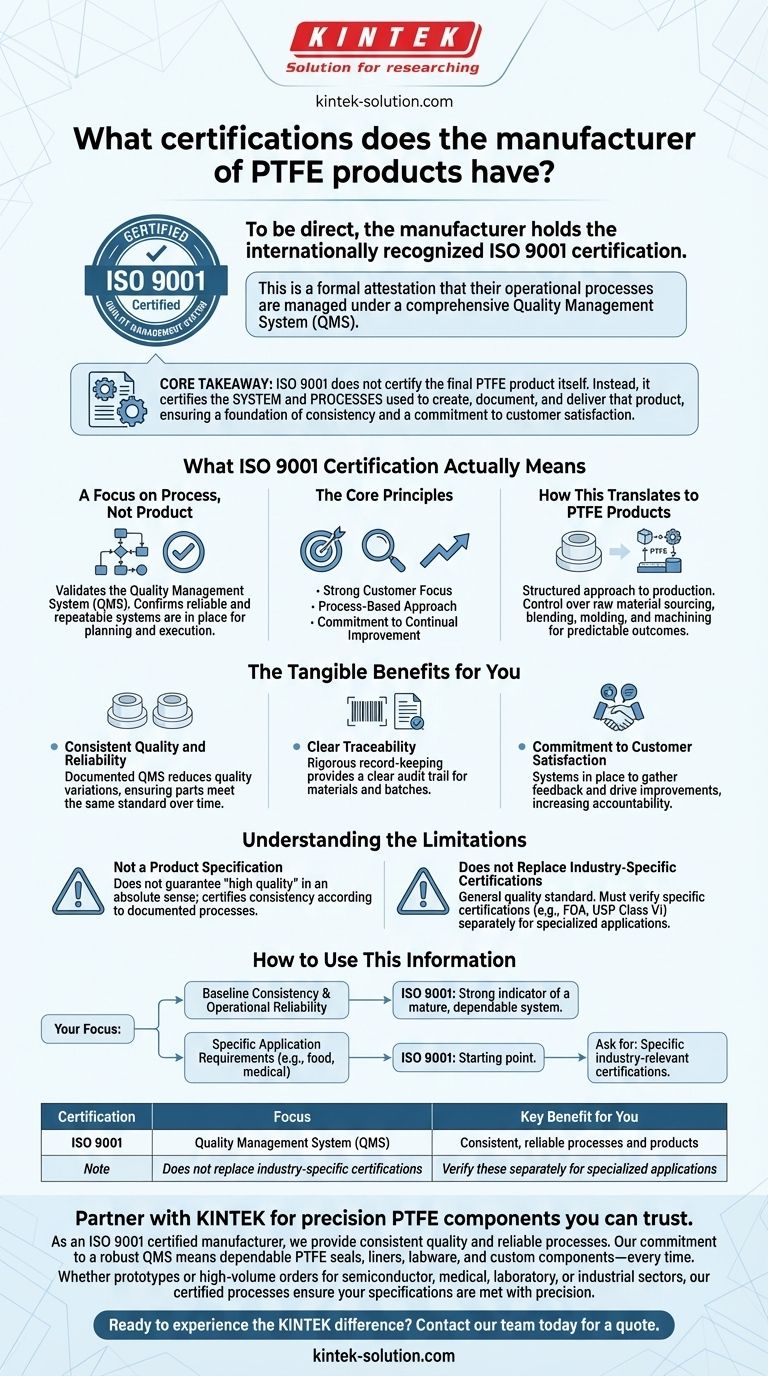

To be direct, the manufacturer holds the internationally recognized ISO 9001 certification. This is a formal attestation that their operational processes are managed under a comprehensive Quality Management System (QMS).

The core takeaway is that ISO 9001 does not certify the final PTFE product itself. Instead, it certifies the system and processes used to create, document, and deliver that product, ensuring a foundation of consistency and a commitment to customer satisfaction.

What ISO 9001 Certification Actually Means

ISO 9001 is one of the most widely adopted quality management standards in the world. Understanding its focus is key to evaluating what it guarantees for you as a customer.

A Focus on Process, Not Product

The certification validates the manufacturer's Quality Management System (QMS). This system is the set of policies, processes, and procedures required for planning and execution in the core business area of an organization.

In simple terms, it confirms the manufacturer has a reliable and repeatable system in place.

The Core Principles of the Standard

The ISO 9001 standard is built on several key principles, including a strong customer focus, a process-based approach to operations, and a commitment to continual improvement.

This means the manufacturer must have documented procedures for everything from handling orders to controlling production and managing non-conforming products.

How This Translates to PTFE Products

For a manufacturer of specialized materials like PTFE, this certification implies a structured approach to production. It suggests control over critical steps like raw material sourcing, blending, molding, and machining, which leads to more predictable outcomes.

The Tangible Benefits for You

An ISO 9001 certified supplier provides several practical advantages that go beyond a simple certificate on the wall.

Consistent Quality and Reliability

The primary benefit is consistency. A documented and audited QMS reduces the risk of random variations in product quality, ensuring that the part you receive today is made to the same standard as the one you receive next year.

Clear Traceability

The standard requires rigorous record-keeping. This provides a clear audit trail, allowing for full traceability of materials and production batches if an issue ever needs to be investigated.

Commitment to Customer Satisfaction

A core tenet of ISO 9001 is meeting and exceeding customer requirements. The manufacturer must have systems in place to gather customer feedback and use it to drive improvements, making them more accountable.

Understanding the Limitations

Objectivity requires acknowledging what ISO 9001 is not. This certification is a crucial indicator of operational maturity, but it has specific boundaries.

It Is Not a Product Specification

ISO 9001 does not guarantee that a product is "high quality" in an absolute sense. A manufacturer could, in theory, consistently produce a low-specification product and still maintain certification, as long as they do it according to their documented process.

It Does Not Replace Industry-Specific Certifications

This is a general quality management standard. It does not replace specific certifications that may be required for certain applications, such as FDA compliance for food-contact materials or USP Class VI for medical devices. You must verify these separately.

How to Use This Information

Use the manufacturer's ISO 9001 certification as a foundational data point in your supplier evaluation process.

- If your primary focus is baseline consistency and operational reliability: The ISO 9001 certification is a strong and positive indicator that the manufacturer has a mature and dependable system in place.

- If your primary focus is meeting specific application requirements (e.g., food, medical, aerospace): View ISO 9001 as the starting point and then ask for the specific, industry-relevant certifications your project demands.

Ultimately, this certification confirms the manufacturer has a robust framework for quality, empowering you to trust the consistency of their process.

Summary Table:

| Certification | Focus | Key Benefit for You |

|---|---|---|

| ISO 9001 | Quality Management System (QMS) | Consistent, reliable processes and products |

| Note: Does not replace industry-specific certifications (e.g., FDA, USP Class VI) | Verify these separately for specialized applications |

Partner with KINTEK for precision PTFE components you can trust.

As an ISO 9001 certified manufacturer, we provide the consistent quality and reliable processes detailed in this article. Our commitment to a robust Quality Management System means you receive dependable PTFE seals, liners, labware, and other custom components—every time.

Whether you need prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, our certified processes ensure your specifications are met with precision.

Ready to experience the KINTEK difference? Contact our team today to discuss your project needs and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments