The primary advantage is predictable and effortless fastening. A low coefficient of friction on a fastener, provided by a Polytetrafluoroethylene (PTFE) coating, ensures smoother assembly and disassembly. This property dramatically reduces the risk of galling or seizing and minimizes wear on threaded components, especially during repeated use.

While the immediate benefit of PTFE's low friction is easier installation, its true value lies in ensuring the long-term integrity and serviceability of a bolted joint, particularly in corrosive or high-maintenance environments.

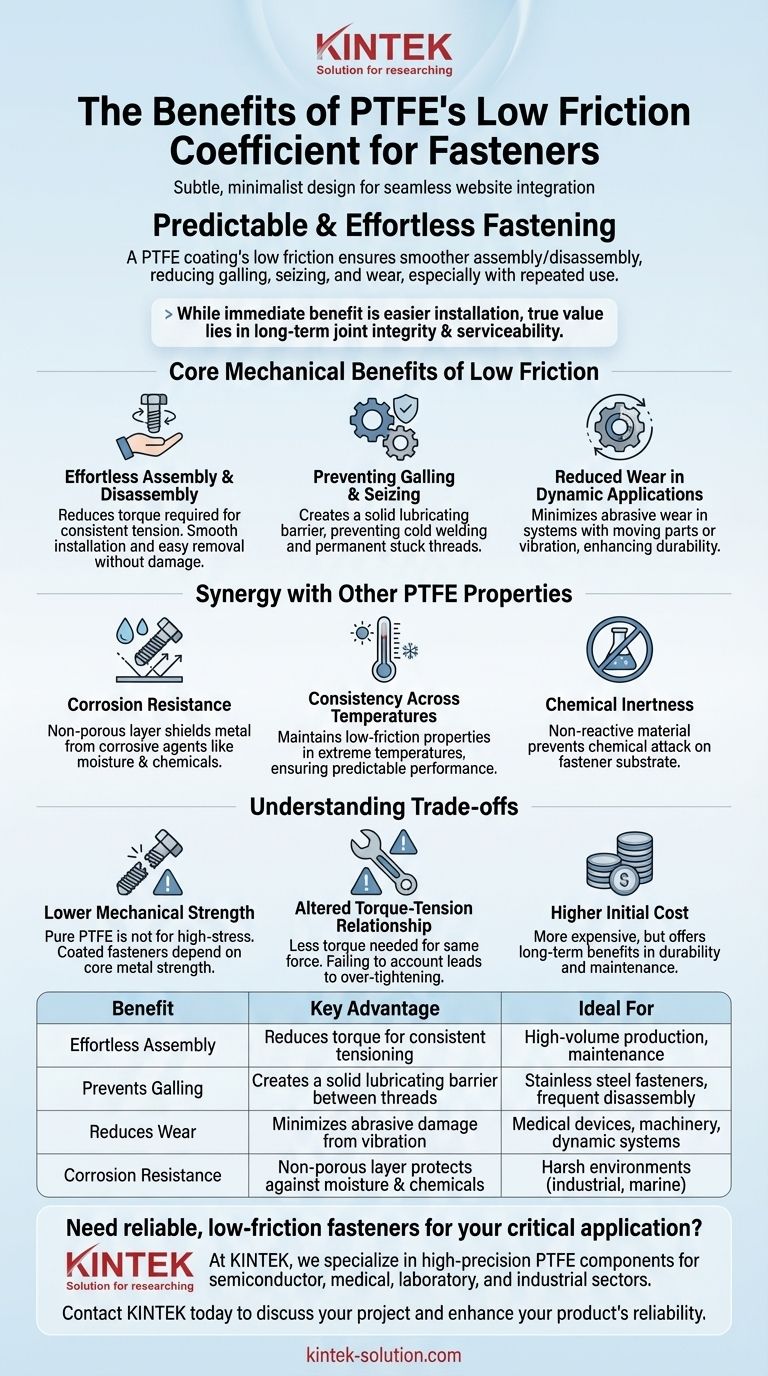

The Core Mechanical Benefits of Low Friction

The slick surface of a PTFE coating fundamentally changes how a fastener behaves under load, providing three distinct mechanical advantages.

Effortless Assembly and Disassembly

The low-friction surface reduces the torque required to tighten a fastener to the desired tension. This makes installation smoother and more consistent.

This same property is critical for disassembly, allowing for easy removal of fasteners without damage, even after long periods of service.

Preventing Galling and Seizing

Galling is a form of cold welding that can occur when metal surfaces, particularly stainless steel, are under high pressure. The threads can bind and become permanently stuck.

A PTFE coating creates a solid, lubricating barrier between the mating threads. This physical separation effectively prevents galling and seizing, which is critical in applications requiring routine maintenance.

Reduced Wear in Dynamic Applications

In systems with moving parts or significant vibration, a low-friction surface minimizes the abrasive wear and tear on the fastener's threads.

This leads to longer component life and enhanced durability, making these fasteners ideal for equipment like medical devices or machinery where smooth operation is paramount.

How Low Friction Complements Other PTFE Properties

The benefit of low friction is magnified when combined with the other inherent characteristics of PTFE. The coating isn't just slick; it's a multi-purpose protective layer.

Synergy with Corrosion Resistance

The same non-porous PTFE layer that reduces friction also shields the underlying metal from corrosive agents like moisture, chemicals, and salt.

This dual-purpose protection ensures the fastener not only turns smoothly but also resists degradation in harsh industrial or marine environments.

Consistency Across Extreme Temperatures

PTFE maintains its low-friction properties across a wide range of temperatures.

This stability is essential for equipment that undergoes sterilization cycles or operates in fluctuating thermal conditions, ensuring predictable performance where traditional lubricants might fail.

Chemical Inertness

PTFE is one of the most non-reactive materials known. This inertness prevents chemical attack on the fastener substrate.

This property ensures that the fastener's mechanical integrity and low-friction surface are not compromised by exposure to aggressive chemicals.

Understanding the Trade-offs

While highly beneficial, PTFE-coated fasteners are not a universal solution. An objective analysis requires acknowledging their limitations.

Lower Mechanical Strength

Pure PTFE fasteners are not as mechanically strong as their all-metal counterparts and are unsuitable for high-stress, load-bearing applications.

For coated fasteners, the strength is determined by the core metal, but the coating itself offers no structural benefit.

Altered Torque-Tension Relationship

The most critical consideration for engineers is that low friction changes the relationship between applied torque and clamping force (tension).

Less torque is needed to achieve the same clamping force. Failing to account for this can easily lead to over-tightening, potentially stripping threads or causing bolt failure. Standard torque values for uncoated fasteners do not apply.

Higher Initial Cost

PTFE coatings and fasteners are more expensive than conventional, uncoated fasteners.

This higher upfront cost must be weighed against the long-term benefits of improved durability, reduced maintenance, and corrosion prevention.

Making the Right Choice for Your Application

Selecting the correct fastener requires matching its properties to your primary engineering goal.

- If your primary focus is frequent maintenance or adjustments: PTFE's anti-galling and low-friction properties are paramount, ensuring components can be disassembled and reassembled reliably without damage.

- If your primary focus is corrosion resistance in harsh environments: The PTFE coating serves as an exceptional dual-purpose barrier, offering both low friction and robust protection from chemicals and moisture.

- If your primary focus is high-load structural integrity: You must use a coated fastener with a high-strength metal core and meticulously recalculate torque specifications to prevent over-tensioning.

By understanding these principles, you can leverage PTFE's unique properties to enhance reliability and serviceability in the correct applications.

Summary Table:

| Benefit | Key Advantage | Ideal For |

|---|---|---|

| Effortless Assembly | Reduces required torque for consistent tensioning | High-volume production, maintenance |

| Prevents Galling | Creates a solid lubricating barrier between threads | Stainless steel fasteners, frequent disassembly |

| Reduces Wear | Minimizes abrasive damage from vibration | Medical devices, machinery, dynamic systems |

| Corrosion Resistance | Non-porous layer protects against moisture & chemicals | Harsh environments (industrial, marine) |

Need reliable, low-friction fasteners for your critical application?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom-coated fasteners for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your fasteners provide predictable performance, prevent seizing, and withstand corrosive environments.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision to meet your exact specifications.

Contact KINTEK today to discuss your project and discover how our PTFE solutions can enhance your product's reliability and serviceability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance