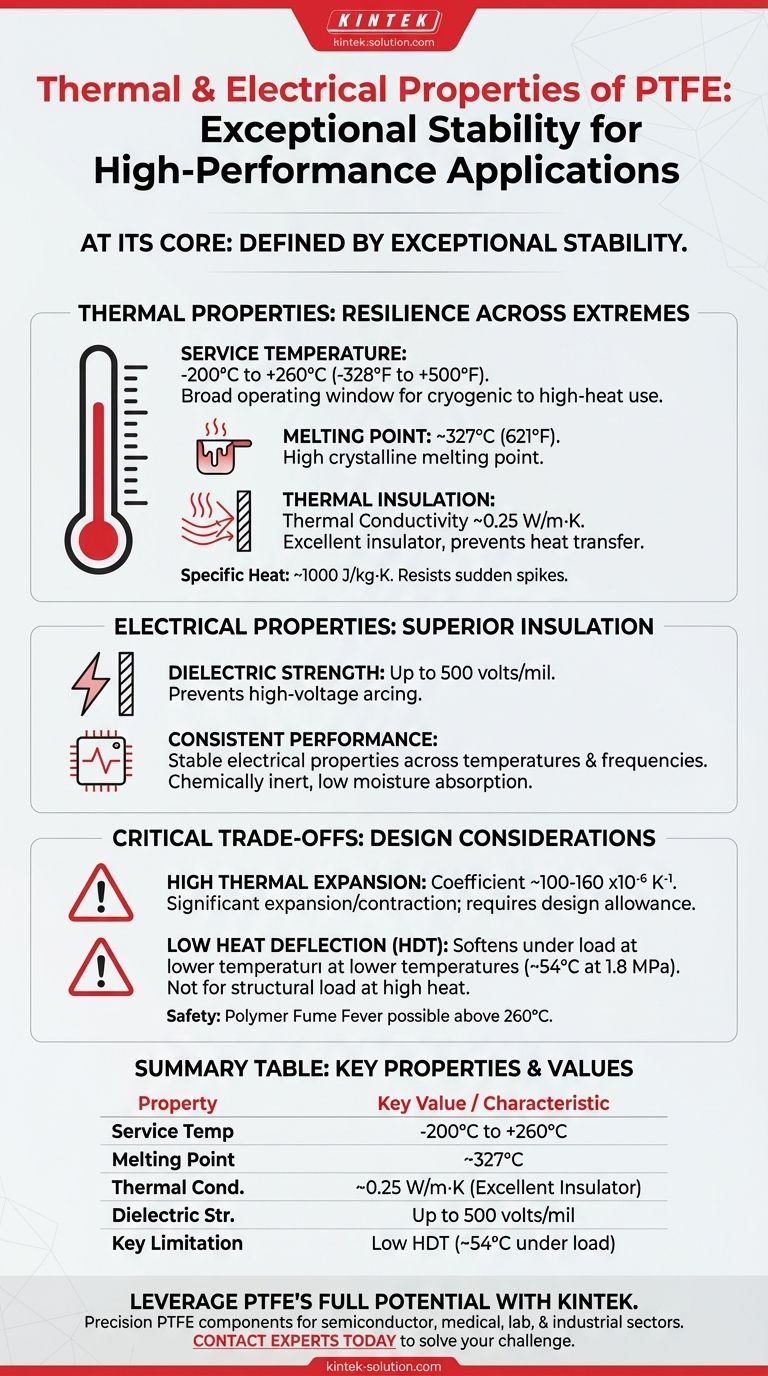

At its core, Polytetrafluoroethylene (PTFE) is defined by its exceptional stability. It is a premier thermal and electrical insulator, capable of performing reliably across an astonishingly wide temperature range. Its continuous service temperature spans from cryogenic lows of -200°C up to 260°C (500°F), with a high melting point around 327°C (621°F), while also offering excellent electrical insulation of up to 500 volts per mil.

The true value of PTFE isn't just its resistance to high heat or voltage, but its ability to maintain its core properties consistently across extreme thermal cycles. Understanding its limitations, particularly under mechanical load, is the key to leveraging its strengths effectively.

Decoding PTFE's Thermal Properties

PTFE's reputation is built on its thermal resilience. It does not degrade or change its fundamental characteristics within its specified service range, making it highly predictable in demanding environments.

An Uncommonly Wide Service Temperature

The most notable thermal property of PTFE is its massive operating window, from -200°C to +260°C (-328°F to +500°F). This allows its use in everything from cryogenic fluid handling to high-temperature industrial seals.

It has a distinct crystalline melting point around 327°C (621°F), far beyond the range of most common polymers.

Excellent Thermal Insulation

PTFE is a poor conductor of heat, making it an effective thermal insulator. Its thermal conductivity is very low, around 0.25 W/m·K.

This property is crucial for applications where you need to prevent heat transfer, such as in gaskets or as a thermal barrier in electronic components.

Specific Heat Capacity

The specific heat of PTFE is approximately 1000 J/kg·K. This means it requires a moderate amount of energy to increase its temperature.

Combined with its low thermal conductivity, this contributes to its overall stability and resistance to sudden temperature spikes.

Understanding the Electrical Insulation

PTFE is one of the best electrical insulating materials available. Its molecular structure is highly stable and non-polar, which prevents the easy flow of electrons.

Superior Dielectric Strength

The key metric for an electrical insulator is its dielectric strength. PTFE can withstand up to 500 volts per mil of thickness.

This means a very thin film of PTFE can prevent high voltages from arcing, making it indispensable for high-performance wire insulation, coaxial cables, and printed circuit boards.

Consistent Performance

Because PTFE is chemically inert and does not absorb water, its electrical properties remain exceptionally stable across a wide range of temperatures and frequencies. This reliability is critical for sensitive electronics and high-frequency communication equipment.

Critical Trade-offs and Considerations

No material is perfect. While PTFE's properties are impressive, its mechanical behavior under heat presents critical design constraints that must be respected.

High Coefficient of Thermal Expansion

PTFE expands and contracts significantly with temperature changes. Its coefficient of thermal expansion is relatively high (around 100-160 x10⁻⁶ K⁻¹).

This must be accounted for in any design with tight tolerances. Parts must have room to change size without warping, cracking, or failing.

Low Heat Deflection Temperature (HDT)

This is a crucial limitation. While PTFE doesn't melt until 327°C, it begins to soften and deform under mechanical load at much lower temperatures.

Its HDT can be as low as 54°C (129°F) under a load of 1.8 MPa. This means PTFE is not suitable for structural applications that must bear weight at elevated temperatures.

Polymer Fume Fever

A critical safety consideration is that heating PTFE above its service temperature of 260°C can cause it to release fumes. Inhaling these fumes can cause temporary, flu-like symptoms known as polymer fume fever. This is a well-known concern, particularly for cookware applications.

Making the Right Choice for Your Goal

To use PTFE successfully, you must align its unique properties with the primary demands of your application.

- If your primary focus is stability in extreme temperatures: PTFE is an elite choice for non-structural parts in both cryogenic and high-heat environments.

- If your primary focus is high-voltage or high-frequency insulation: PTFE's outstanding dielectric strength and low moisture absorption make it a top-tier material.

- If your primary focus is a structural component under load: You must carefully evaluate the operating temperature and ensure it remains well below PTFE's heat deflection temperature to avoid deformation.

By understanding both its remarkable strengths and its clear limitations, you can make an informed decision and leverage PTFE's full potential.

Summary Table:

| Property | Key Value / Characteristic |

|---|---|

| Service Temperature | -200°C to +260°C (-328°F to +500°F) |

| Melting Point | ~327°C (621°F) |

| Thermal Conductivity | ~0.25 W/m·K (Excellent Insulator) |

| Dielectric Strength | Up to 500 volts/mil |

| Key Limitation | Low Heat Deflection Temperature (~54°C under load) |

Leverage PTFE's Full Potential with KINTEK

Understanding PTFE's properties is the first step. Applying them effectively is where KINTEK excels. We manufacture precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We ensure your designs account for thermal expansion and mechanical limits, delivering reliable performance from prototypes to high-volume production.

Ready to solve your high-temperature or electrical insulation challenge? Contact our experts today to discuss your specific application and receive a custom solution.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What is Teflon and what are its alternative names? Understanding PTFE, the Material Behind the Brand

- How was PTFE discovered and developed? From Lab Accident to Essential High-Performance Polymer

- What environmental resistances does PTFE offer? Unmatched Durability for Harsh Conditions

- When was PTFE discovered and developed? The Accidental Invention That Changed Industries

- What is PTFE and what class of plastics does it belong to? A Guide to High-Performance Fluoropolymers