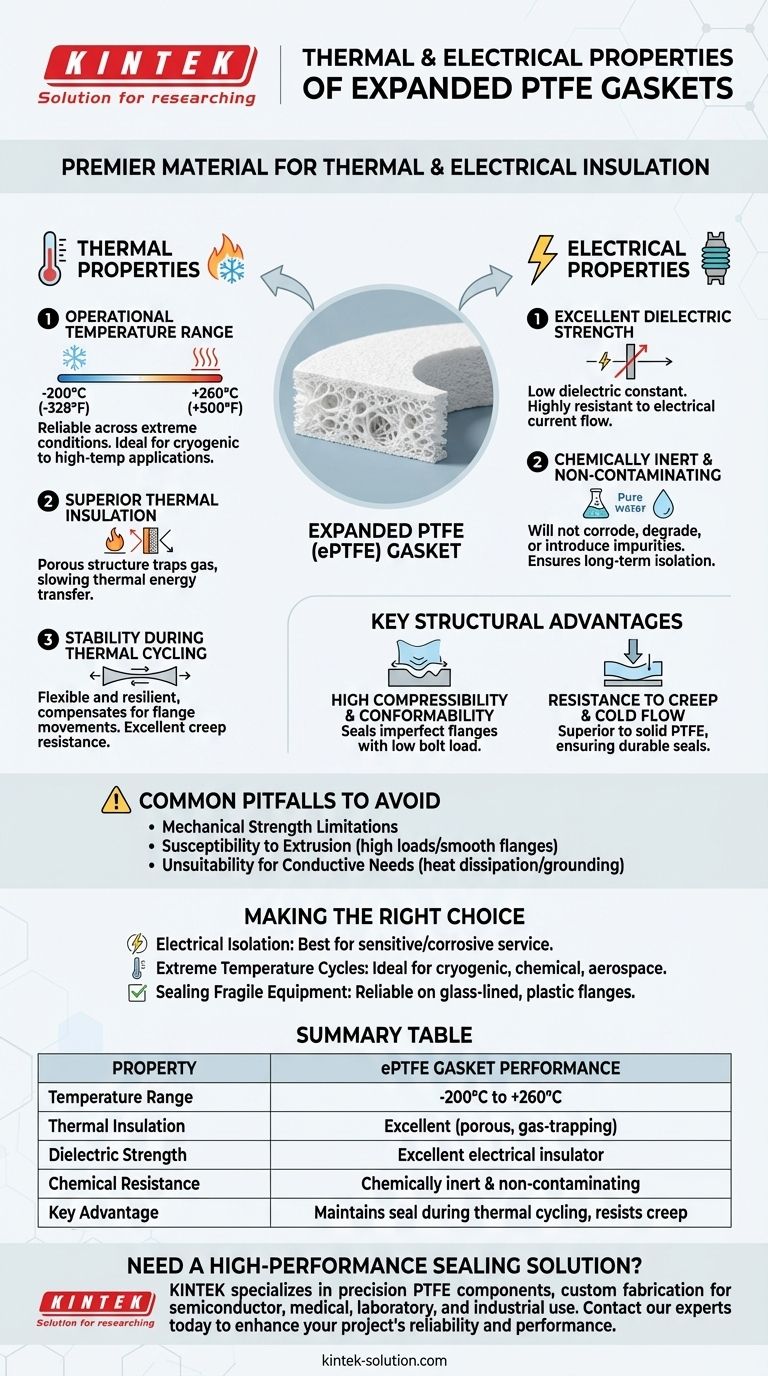

In short, expanded PTFE (ePTFE) is a premier material for both thermal and electrical insulation. It functions reliably across an extremely wide temperature range, from cryogenic conditions up to +260°C (-328°F to +500°F). Its unique porous structure and the inherent chemical inertness of PTFE also make it an outstanding electrical insulator with a low dielectric constant.

The core reason for ePTFE's exceptional performance is its manufacturing process, which transforms solid PTFE into a soft, porous, and flexible structure. This structure excels at trapping gas, which dramatically reduces thermal transfer and provides the compliance needed to maintain a seal during thermal cycling.

Analyzing the Thermal Properties

The thermal characteristics of ePTFE gaskets make them suitable for some of the most demanding industrial applications, from chemical processing to aerospace.

The Operational Temperature Range

Expanded PTFE gaskets maintain their integrity and sealing capability in continuous service from -200°C to +260°C. This vast range means they are equally effective in cryogenic applications as they are in high-temperature chemical reactors.

Superior Thermal Insulation

The material's porous, expanded structure is key to its insulating power. The microscopic voids within the ePTFE trap gas, which is a poor conductor of heat. This significantly slows the transfer of thermal energy across the gasket, helping to maintain temperature differentials.

Stability During Thermal Cycling

Because ePTFE is highly flexible and resilient, it effectively compensates for the expansion and contraction of flange surfaces during temperature fluctuations. This, combined with its excellent creep resistance, ensures a long-term, reliable seal where other materials might fail.

Understanding the Electrical Properties

Virgin PTFE is one of the best electrical insulators known, and the expanded form retains these elite properties.

Excellent Dielectric Strength

Expanded PTFE has excellent dielectric properties and a low dielectric constant. This means it is highly resistant to conducting electricity and is effective at preventing the flow of current between flange faces.

Chemically Inert and Non-Contaminating

The material is chemically inert and non-contaminating. In electrical applications, this is critical because it ensures the gasket will not corrode, degrade, or introduce impurities that could compromise electrical isolation over the product's service life.

Key Structural Advantages

The physical form of ePTFE is inseparable from its thermal and electrical performance. It is this structure that allows it to outperform standard, solid PTFE in many sealing applications.

High Compressibility and Conformability

Unlike solid PTFE, ePTFE is very soft and compressible. This allows it to easily conform to and seal imperfect or irregular flange surfaces, which are common in real-world industrial equipment.

Resistance to Creep and Cold Flow

A known weakness of solid PTFE is its tendency to "flow" or "creep" away from a compressive load over time, leading to a loss of bolt torque and potential leaks. The expanded, multi-directional fibrous structure of ePTFE provides superior resistance to creep and cold flow, ensuring a more stable and durable seal.

Common Pitfalls to Avoid

While ePTFE is a high-performance material, its unique properties introduce specific trade-offs that are critical to understand for correct application.

Mechanical Strength Limitations

Expanded PTFE is a soft material by design. It does not have the high compressive strength or rigidity of filled PTFE or metallic gaskets. It should not be used in applications where the gasket itself is required to provide significant structural support.

Susceptibility to Extrusion

Because it is so soft, ePTFE can be squeezed out, or "extruded," from between flanges if the bolt load is excessively high or the flange surfaces are too smooth and narrow. Proper bolt torque procedures and flange design are essential.

Unsuitability for Conductive Needs

This is an obvious but crucial point. If your application requires the dissipation of heat or the grounding of static electricity through the gasket, ePTFE is fundamentally the wrong choice.

Making the Right Choice for Your Application

Selecting the right gasket material requires matching its properties to your primary engineering goal.

- If your primary focus is electrical isolation: The high dielectric strength and chemical inertness of ePTFE make it a first-class choice for insulating flanges in sensitive or corrosive service.

- If your primary focus is sealing across extreme temperature cycles: The material's vast operational temperature range and excellent flexibility make it ideal for cryogenic, chemical, and aerospace applications.

- If your primary focus is sealing fragile or damaged equipment: ePTFE's softness allows it to create a reliable seal on glass-lined, plastic, or slightly damaged metal flanges with minimal bolt force.

By understanding these core thermal and electrical properties, you can confidently specify ePTFE for applications where insulation and sealability are paramount.

Summary Table:

| Property | ePTFE Gasket Performance |

|---|---|

| Temperature Range | -200°C to +260°C (-328°F to +500°F) |

| Thermal Insulation | Excellent (due to porous, gas-trapping structure) |

| Dielectric Strength | Excellent electrical insulator |

| Chemical Resistance | Chemically inert and non-contaminating |

| Key Advantage | Maintains seal during thermal cycling and resists creep |

Need a high-performance sealing solution?

KINTEK specializes in manufacturing precision PTFE components, including expanded PTFE gaskets, seals, liners, and labware. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the exact insulation and sealing properties your application demands, whether for semiconductor, medical, laboratory, or industrial use.

Contact our experts today to discuss how our PTFE solutions can enhance your project's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability