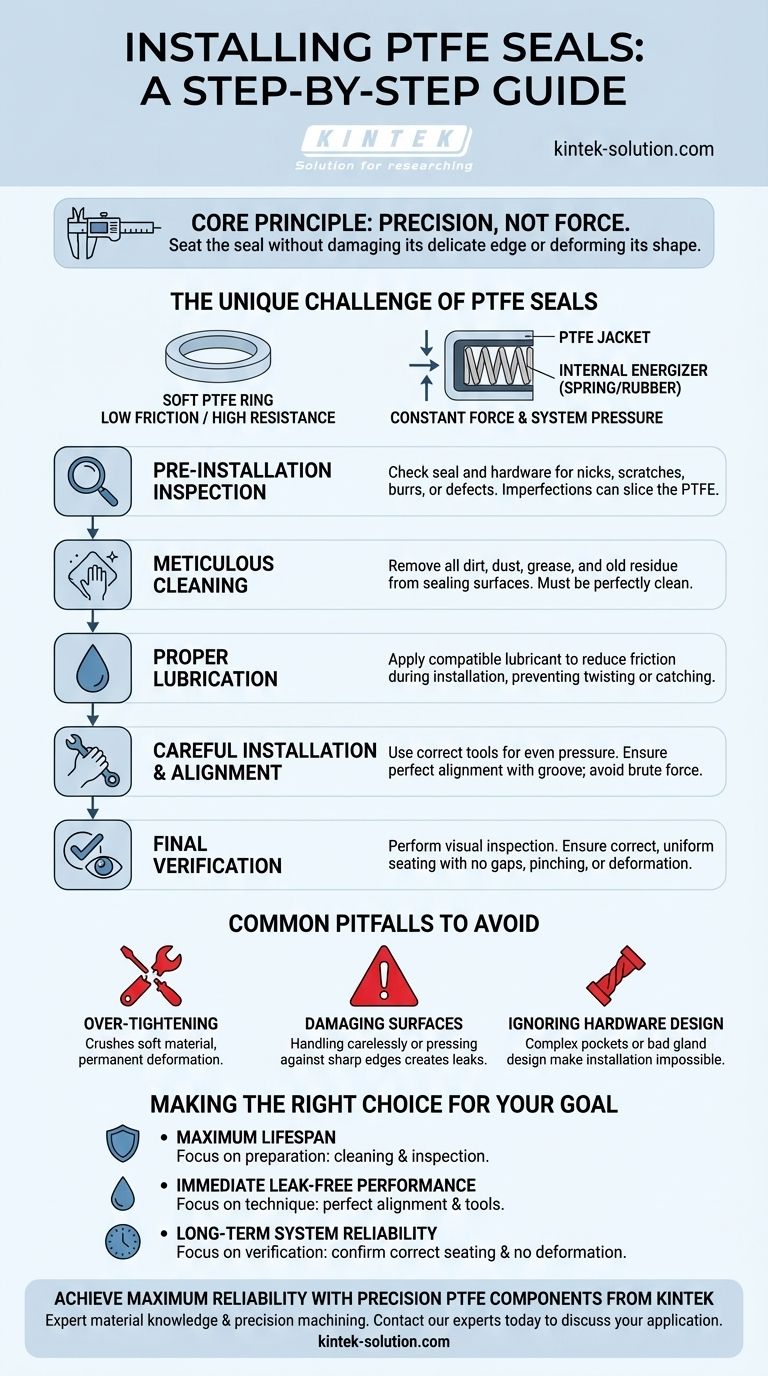

The essential steps for installing a PTFE seal are inspection, cleaning, lubrication, careful installation with proper tools, and final verification. Unlike a simple rubber O-ring, a PTFE seal's effectiveness relies heavily on a precise installation that respects the material's unique properties to avoid deformation and ensure a reliable, long-lasting seal.

The core principle of PTFE seal installation is precision, not force. The goal is to seat the seal without damaging its delicate sealing edge or permanently deforming its shape, as this is the primary cause of premature failure and leaks.

The Unique Challenge of PTFE Seals

Polytetrafluoroethylene (PTFE) is a high-performance polymer known for its extremely low friction and high chemical resistance. However, it is also a relatively soft material that can be easily scratched or deformed.

Understanding the Components

Most high-performance PTFE seals are not just a single piece of plastic. They are typically energized seals, consisting of a machined PTFE jacket and an internal energizer, which is often a spring or a rubber element.

When installed, this energizer is compressed. It acts like a spring, pushing the PTFE jacket outwards against the sealing surfaces. This constant force creates a tight barrier, and when system pressure is applied, it reinforces this force for an even tighter seal.

Why Technique Matters

Because PTFE is not as elastic as rubber, it does not "snap back" into shape if it is over-stretched or deformed during installation. Careless handling can create permanent flat spots or damage the sealing lip, creating a leak path before the equipment is ever turned on.

The Installation Protocol: A Step-by-Step Guide

Following a meticulous process is the only way to guarantee a reliable, leak-free seal.

Step 1: Pre-Installation Inspection

Before you begin, inspect both the seal and the hardware. Check the new PTFE seal for any nicks, scratches, or manufacturing defects.

Crucially, inspect the hardware itself. Ensure there are no burrs, sharp edges, or scratches in the seal gland or on the shaft. Any imperfection on the metal surfaces can slice or damage the soft PTFE material during installation.

Step 2: Meticulous Cleaning

The sealing surfaces must be perfectly clean. Remove all dirt, dust, grease, and old sealant residue from the gland and mating parts. A clean, smooth surface is essential for the seal to function correctly.

Step 3: Proper Lubrication

Apply a clean, compatible lubricant to the seal and the installation surfaces. This is not for sealing but to reduce friction during installation, helping the seal slide into place smoothly without twisting or catching on a sharp edge.

Step 4: Careful Installation & Alignment

This is the most critical stage. Never use brute force. The installation should be a gradual, controlled process.

Use the correct tools designed for seal installation, which provide even pressure. Ensure the seal is perfectly aligned with the groove and is not cocked or twisted. Misalignment will cause uneven wear and lead to premature failure.

Step 5: Final Verification

Once the seal is in place, perform a final visual inspection. Ensure the seal sits correctly and evenly within the gland. There should be no visible gaps, pinching, or signs of deformation. The seal should look uniform all the way around.

Common Pitfalls to Avoid

Understanding what can go wrong is as important as knowing the right steps. Avoiding these common mistakes is key to a successful installation.

The Risk of Over-Tightening

If your application uses bolts or a torque wrench, follow the manufacturer's specifications precisely. Over-tightening is a primary cause of failure. It can crush the soft PTFE material, deforming it permanently and destroying its ability to seal effectively.

The Danger of Damaging Sealing Surfaces

Always handle the seal with care. Dropping it or pressing it against a sharp edge can create an imperceptible flaw that becomes a major leak under pressure. Protect the sealing line and any raised surfaces on the hardware from damage.

Ignoring Hardware Design

Sometimes, a difficult installation points to a problem with the hardware design. Complex machined pockets that require the seal to be bent or twisted significantly make a successful installation nearly impossible. Proper gland design, sometimes using flanges or retainers, is critical for accommodating the seal.

Making the Right Choice for Your Goal

Your approach to installation should align with your primary objective for the equipment.

- If your primary focus is maximum seal lifespan: Pay closest attention to the preparation phase—meticulously inspecting and cleaning the hardware to eliminate any burrs or contamination.

- If your primary focus is immediate leak-free performance: Concentrate on the installation technique itself, ensuring perfect alignment and the use of correct tools to apply even, gradual pressure.

- If your primary focus is long-term system reliability: Emphasize the final verification, confirming the seal is seated correctly and not deformed, which prevents hidden issues from causing failure down the line.

Ultimately, successful PTFE sealing is a function of discipline and precision, not effort.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Inspection | Check seal & hardware for damage | Prevent installation on flawed surfaces |

| 2. Cleaning | Remove all dirt, grease, and residue | Ensure a perfect sealing surface |

| 3. Lubrication | Apply a compatible lubricant | Reduce friction for smooth installation |

| 4. Installation | Use proper tools for even, aligned pressure | Seat the seal without damage or twisting |

| 5. Verification | Confirm correct, uniform seating | Final check for gaps or deformation |

Achieve maximum reliability with precision PTFE components from KINTEK.

Proper installation is critical, but it starts with a perfectly manufactured seal. KINTEK specializes in high-performance PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. We combine expert material knowledge with precision machining to deliver components that meet the most demanding specifications.

Whether you need standard parts or custom fabrication—from prototypes to high-volume orders—our team ensures your seals are built for a perfect fit and long service life.

Don't let seal failure compromise your equipment. Contact our experts today to discuss your application and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F