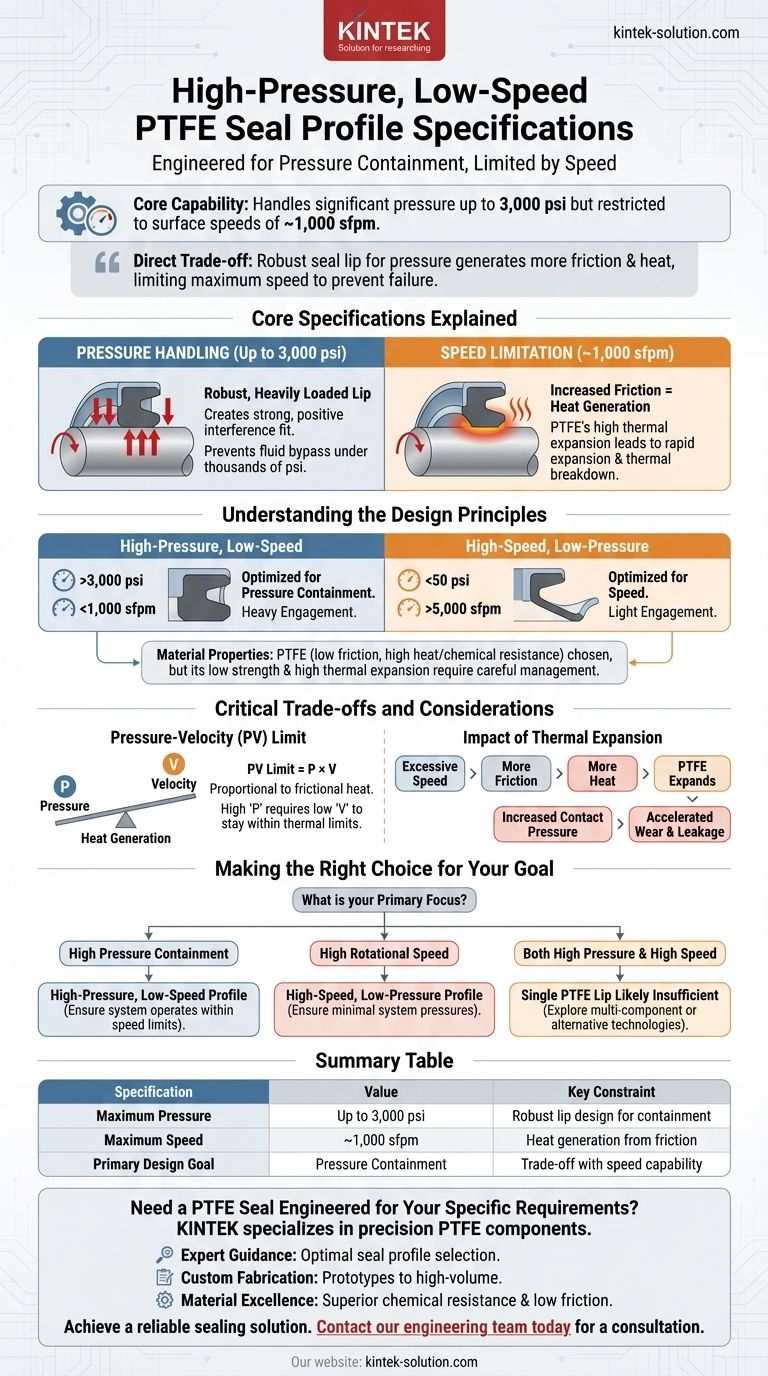

In short, a high-pressure, low-speed PTFE seal profile is specifically engineered to handle significant system pressures, but this capability comes at the cost of rotational speed. This type of seal can reliably operate at pressures up to 3,000 psi but is restricted to surface speeds of approximately 1,000 surface feet per minute (sfpm).

The core principle is a direct trade-off: the robust seal lip design required to contain high pressure generates more friction and heat, which in turn fundamentally limits the maximum permissible speed to prevent material failure.

The Core Specifications Explained

To understand why these limits exist, we must look at the design philosophy behind the seal profile. The geometry and material properties are optimized for one primary function—pressure containment—which directly influences its other capabilities.

Pressure Handling (Up to 3,000 psi)

A high-pressure seal features a robust, heavily loaded lip. This design creates a strong, positive interference fit against the shaft.

This significant engagement is necessary to form a barrier strong enough to prevent fluid from bypassing the seal under thousands of pounds per square inch of pressure.

Speed Limitation (~1,000 sfpm)

The downside of this heavy lip engagement is increased friction. As the shaft rotates, this friction generates heat at the contact point.

PTFE has a high coefficient of thermal expansion. Excessive speed would generate heat faster than it can dissipate, causing the seal lip to expand, further increasing friction and leading to a rapid thermal breakdown and failure.

Understanding the Design Principles

The performance specifications are not arbitrary; they are a direct result of material properties and mechanical design choices. The contrast with a high-speed seal makes this relationship clear.

The Role of PTFE Material Properties

Polytetrafluoroethylene (PTFE) is chosen for its extremely low friction and exceptional chemical and temperature resistance.

However, its relatively low strength and high thermal expansion are critical weaknesses that the seal design must accommodate. The 1,000 sfpm limit is a direct consequence of managing heat buildup and thermal expansion.

Design Contrast: High-Pressure vs. High-Speed

A high-speed, low-pressure profile is the complete opposite. It uses a lightly loaded, flexible lip with minimal shaft engagement.

This design minimizes friction and heat, allowing for speeds up to 5,000 sfpm. However, this light touch makes it incapable of containing significant pressure, typically limiting it to around 50 psi.

Critical Trade-offs and Considerations

Choosing a seal profile requires acknowledging the inherent engineering compromises. You cannot maximize both pressure and speed in a single, simple design.

The Pressure-Velocity (PV) Limit

Every seal operates under a "PV limit," which is the product of pressure (P) and velocity (V). This value is proportional to the frictional heat generated.

A high-pressure, low-speed seal is designed to handle a high "P" value, which means the "V" value must be kept low to stay within the material's thermal limits.

The Impact of Thermal Expansion

If a high-pressure seal is operated above its speed limit, a destructive feedback loop begins. More speed creates more heat, which causes the PTFE to expand.

This expansion increases the contact pressure on the shaft, which generates even more friction and heat, leading to accelerated wear and leakage.

Making the Right Choice for Your Goal

Selecting the correct seal profile requires a clear understanding of your application's primary demand.

- If your primary focus is containing high pressure: The high-pressure, low-speed profile is the correct choice, provided you design the system to operate within its speed limitations.

- If your primary focus is accommodating high rotational speed: You must use a high-speed, low-pressure profile and ensure system pressures remain minimal.

- If your application demands both high pressure and high speed: A single PTFE lip seal is likely insufficient, requiring you to explore multi-component sealing systems or alternative technologies.

Understanding this fundamental inverse relationship between pressure containment and speed is the key to designing a reliable and effective sealing system.

Summary Table:

| Specification | Value | Key Constraint |

|---|---|---|

| Maximum Pressure | Up to 3,000 psi | Robust lip design for containment |

| Maximum Speed | ~1,000 sfpm | Heat generation from friction |

| Primary Design Goal | Pressure Containment | Trade-off with speed capability |

Need a PTFE Seal Engineered for Your Specific Pressure and Speed Requirements?

KINTEK specializes in the precision manufacturing of PTFE components, including custom seals for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. We understand the critical balance between pressure and velocity.

We provide:

- Expert Guidance: Helping you select or design the optimal seal profile for your unique operating conditions.

- Custom Fabrication: From initial prototypes to high-volume production runs, ensuring a perfect fit and function.

- Material Excellence: Leveraging the properties of PTFE for superior chemical resistance and low friction.

Let us help you achieve a reliable and efficient sealing solution. Contact our engineering team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance