Machining PTFE requires a complete shift in mindset from traditional materials. Unlike metals, the challenge isn't overcoming hardness but taming its unique softness, high thermal expansion, and tendency to deform under pressure. The key considerations involve using exceptionally sharp tools, managing heat buildup with precise speeds, and employing specialized workholding to prevent the material from warping or compressing.

PTFE is deceptively easy to cut but difficult to machine to a tight tolerance. Success does not come from the cutting action itself, but from strategically managing the material's inherent instability—its thermal expansion and stress creep—throughout the entire process.

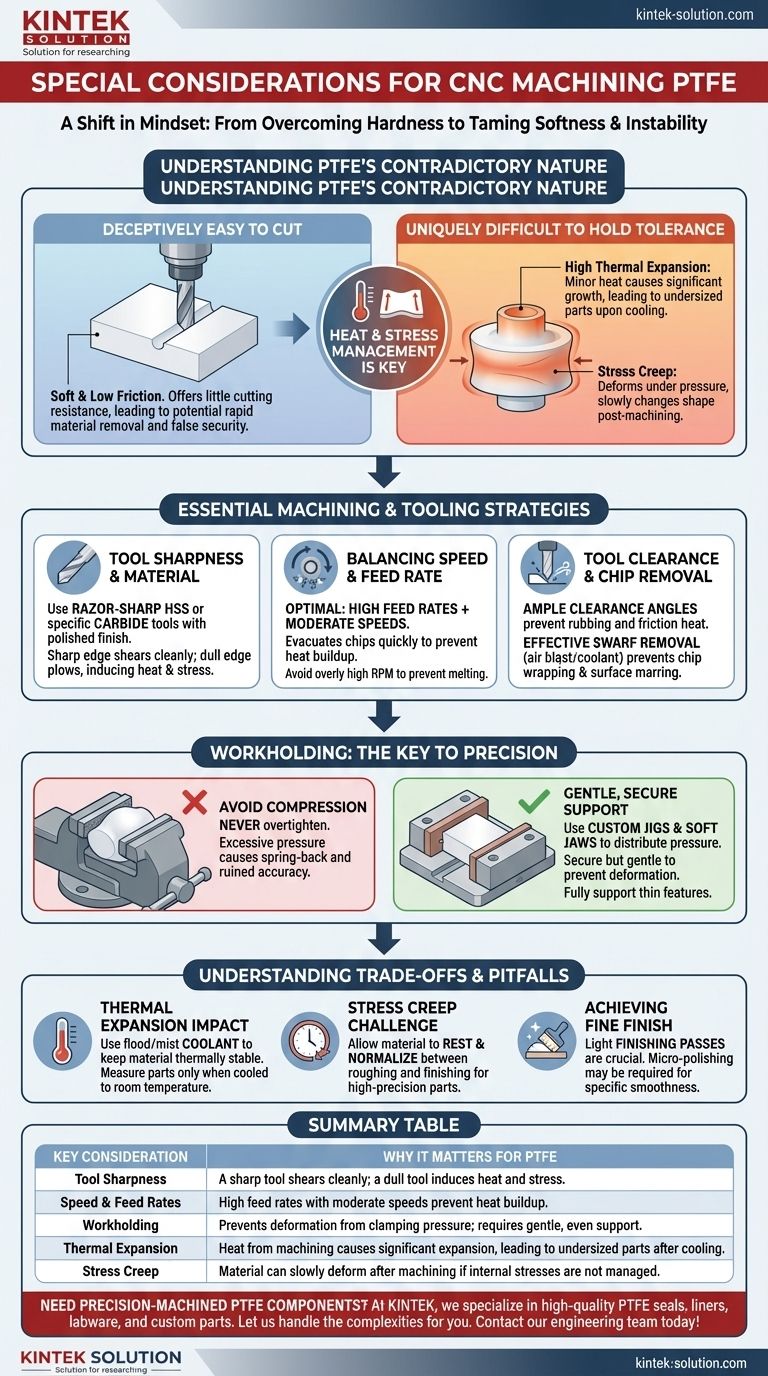

Understanding PTFE's Contradictory Nature

To machine Polytetrafluoroethylene (PTFE) effectively, you must first understand its core properties. Its greatest strengths in application are often its greatest weaknesses on the CNC machine.

Deceptively Easy to Cut

PTFE's softness and low coefficient of friction mean it offers very little resistance to a cutting tool. This can give a false sense of security, as the material can be removed very quickly and easily.

Uniquely Difficult to Hold Tolerance

The real challenge lies in dimensional accuracy. PTFE has two properties that make precision difficult: a high coefficient of thermal expansion and a tendency for stress creep.

Even minor heat from the cutting process can cause the part to expand significantly. Once it cools, it will shrink, resulting in an undersized feature. Similarly, it deforms easily under pressure and can slowly "creep" or change shape after being unclamped.

Essential Machining & Tooling Strategies

Your tooling and cutting parameters must be tailored to accommodate PTFE's delicate nature. The goal is to shear the material cleanly without introducing heat or stress.

The Critical Role of Tool Sharpness

Tools must be razor-sharp with a smooth, polished finish. Use High-Speed Steel (HSS) or specific grades of carbide designed for plastics. A sharp edge cleanly shears the material, while a dull edge will plow through it, inducing stress and heat.

Balancing Speed and Feed Rate

The optimal approach is to use high feed rates combined with moderate cutting speeds. This creates a chip and evacuates it from the cutting zone quickly, preventing heat from soaking into the material. Overly high spindle speeds (RPM) will cause friction, leading to melting.

The Importance of Tool Clearance

Ensure your cutting tools have ample clearance or relief angles. This prevents the non-cutting edge of the tool from rubbing against the freshly machined surface, which is a primary source of frictional heat.

Managing Chip Removal (Swarf)

PTFE produces long, continuous, and stringy chips that can wrap around the tool and spindle. Effective swarf removal, often with a directed air blast or coolant, is necessary to prevent this and to avoid marring the part's surface finish.

Workholding: The Key to Precision

How you hold the workpiece is just as important as how you cut it. Improper clamping is a leading cause of failure when machining PTFE.

Avoiding Compression and Deformation

Never overtighten a vise or clamp. Excessive pressure will compress the material, and when the part is finished and released, it will spring back, ruining your dimensional accuracy.

Custom jigs and soft jaws are often used to distribute clamping pressure evenly. The goal is to hold the part securely enough that it doesn't move, but gently enough that it doesn't deform.

Supporting the Material

Because PTFE is so flexible, thin walls or features must be fully supported from behind. Without proper support, the material will simply push away from the cutting tool, resulting in an inaccurate and inconsistent cut.

Understanding the Trade-offs and Pitfalls

Successfully machining PTFE means actively managing its inherent weaknesses. Ignoring these factors will lead to scrapped parts.

The Impact of Thermal Expansion

A part measured while still warm from machining will appear to be on-spec. After it cools to room temperature, it may be significantly undersized. Using a flood or mist coolant is highly effective at keeping the material thermally stable during the operation.

The Challenge of Stress Creep

Internal stresses induced during manufacturing or from improper clamping can cause the part to change shape hours or even days after machining. For ultra-high-precision parts, allowing the material to rest and normalize between roughing and finishing passes is a common strategy.

Achieving a Fine Surface Finish

While easy to cut, achieving a perfectly smooth surface can be difficult due to PTFE's softness. Finishing passes must be very light, and in some cases, techniques like micro-polishing may be required to meet specific requirements.

How to Apply This to Your Project

Your strategy should adapt based on the final requirements of the part.

- If your primary focus is prototyping or non-critical components: Prioritize using extremely sharp tools and proper workholding to get a functional part quickly.

- If your primary focus is achieving tight tolerances (+/- 0.002”): You must actively manage temperature with coolant and consider multi-pass strategies to allow material stresses to normalize.

- If you are outsourcing the work: Ask potential vendors specifically about their experience with PTFE and their methods for workholding and controlling thermal expansion.

Ultimately, mastering PTFE machining is an exercise in respecting the material's properties and adapting your process to its unique behavior.

Summary Table:

| Key Consideration | Why It Matters for PTFE |

|---|---|

| Tool Sharpness | A sharp tool shears cleanly; a dull tool induces heat and stress. |

| Speed & Feed Rates | High feed rates with moderate speeds prevent heat buildup. |

| Workholding | Prevents deformation from clamping pressure; requires gentle, even support. |

| Thermal Expansion | Heat from machining causes significant expansion, leading to undersized parts after cooling. |

| Stress Creep | Material can slowly deform after machining if internal stresses are not managed. |

Need precision-machined PTFE components you can rely on?

At KINTEK, we specialize in manufacturing high-quality PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise lies in mastering the unique challenges of PTFE to deliver parts that meet your most demanding specifications, from prototypes to high-volume production runs.

Let us handle the complexities of PTFE machining for you. Contact our engineering team today to discuss your project and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs