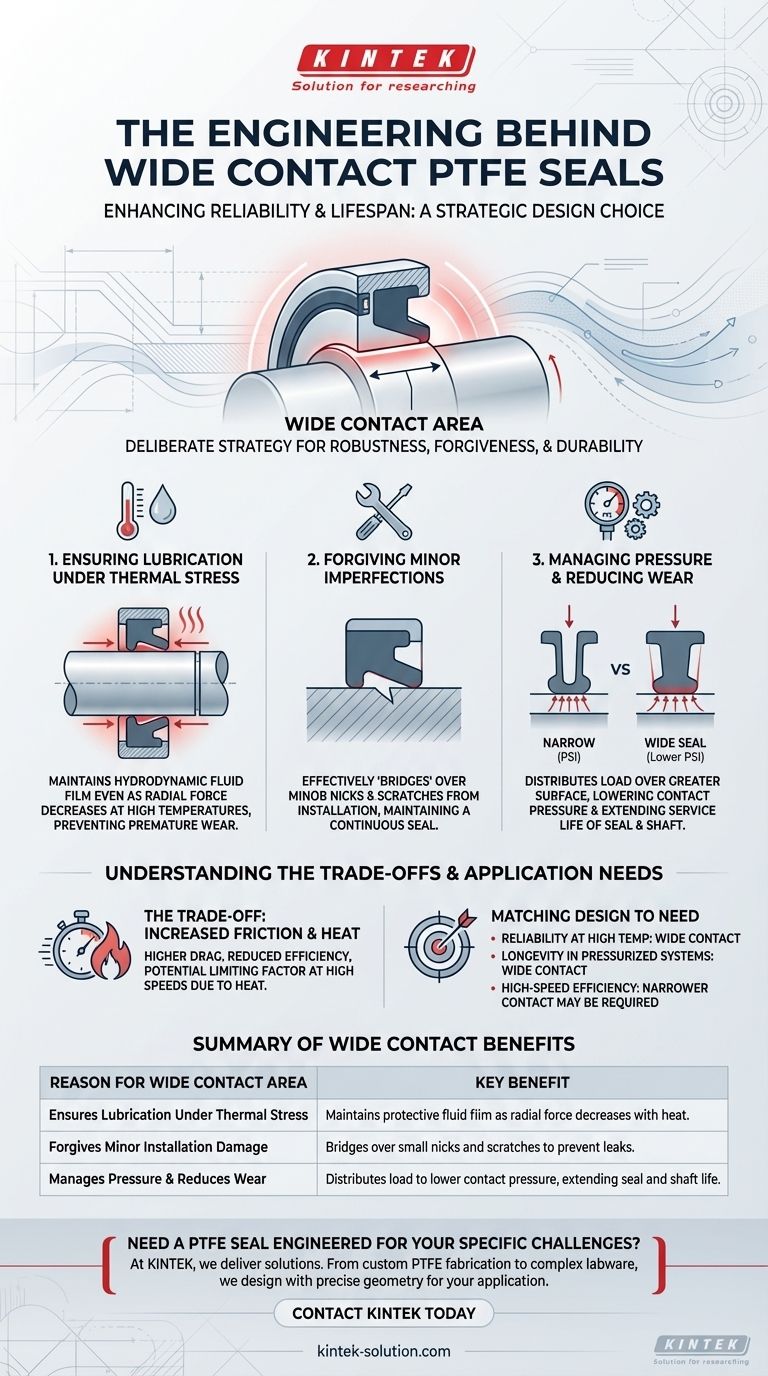

The primary reasons for designing a wide contact area in a PTFE sealing element are to enhance its reliability and lifespan across a range of operational challenges. This design choice intentionally maintains a lubricating fluid film under thermal stress, forgives minor installation damage, and reduces wear by distributing pressure more effectively.

A wide contact area is not an incidental feature; it is a deliberate engineering strategy to make the seal more robust, forgiving, and durable, particularly in applications involving high temperatures or fluid pressure.

The Strategic Role of a Wide Contact Area

The geometry of a seal's contact point is fundamental to its performance. By increasing the width of this area, engineers build in a factor of safety that addresses several common failure modes before they can occur.

Ensuring Lubrication Under Thermal Stress

PTFE, like many polymers, can lose some of its radial force when exposed to elevated temperatures. This reduction can compromise the seal's contact with the shaft.

A wide contact area helps maintain the necessary hydrodynamic fluid film between the seal lip and the shaft, even when this radial load is reduced. This ensures proper lubrication is sustained, preventing premature wear and failure.

Forgiving Minor Imperfections

Sealing elements are often installed in tight spaces, and minor nicks or scratches from handling or installation tools are a practical reality.

A narrow contact point is highly vulnerable to such damage, as even a small imperfection can create a direct leak path. A wider contact area has enough surface to effectively "bridge" over these minor nicks, maintaining a continuous seal.

Managing Pressure and Reducing Wear

In applications where the seal must contain fluid under pressure, that pressure exerts force on the sealing element. This force is concentrated at the contact point.

By designing a wider contact area, the load is distributed over a greater surface. This lowers the contact pressure (measured in psi), which in turn reduces the rate of wear on both the PTFE element and the shaft it runs against, significantly extending the service life of both components.

Understanding the Trade-offs

While beneficial in many scenarios, a wide contact area is an engineering compromise with specific downsides that must be considered. It is not a universally superior design.

The Potential for Increased Friction

The most direct trade-off of a wider contact area is an increase in running friction. More surface-to-surface contact inherently generates more drag.

This can lead to higher torque requirements and reduced energy efficiency in the system, which may be unacceptable in certain low-power applications.

Heat Generation at High Speeds

Increased friction directly translates to increased heat generation. In high-speed rotational applications, the heat buildup from a wide contact patch can become a limiting factor.

Excessive heat can accelerate material degradation, reduce fluid viscosity, and potentially lead to thermal runaway and premature seal failure.

Matching Seal Design to Application Needs

Ultimately, the ideal contact area width is determined by the specific demands of the application. Understanding these principles allows you to select the most appropriate design.

- If your primary focus is reliability at high temperatures: A wide contact area is critical to maintain the lubricating film as the material's radial force changes.

- If your primary focus is longevity in a pressurized system: A wide contact area is necessary to distribute the load and minimize wear on the seal and shaft.

- If your primary focus is high-speed efficiency: A narrower contact area may be required to minimize frictional heat generation, even if it sacrifices some robustness.

Choosing the right seal means understanding how its design geometry is engineered to solve a specific set of operational problems.

Summary Table:

| Reason for Wide Contact Area | Key Benefit |

|---|---|

| Ensures Lubrication Under Thermal Stress | Maintains a protective fluid film as PTFE's radial force decreases with heat. |

| Forgives Minor Installation Damage | Bridges over small nicks and scratches to prevent leaks. |

| Manages Pressure & Reduces Wear | Distributes load to lower contact pressure, extending seal and shaft life. |

Need a PTFE Seal Engineered for Your Specific Challenges?

At KINTEK, we don't just supply seals; we deliver solutions. Our expertise in custom PTFE fabrication means we can design sealing elements—from seals and liners to complex labware—with the precise geometry, including the ideal contact area, to maximize performance in your application.

Whether you're in the semiconductor, medical, laboratory, or industrial sector and require prototypes or high-volume orders, we prioritize precision production to ensure reliability, longevity, and efficiency.

Contact KINTEK today to discuss your sealing requirements and let our experts help you select or custom-design the perfect PTFE component.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support