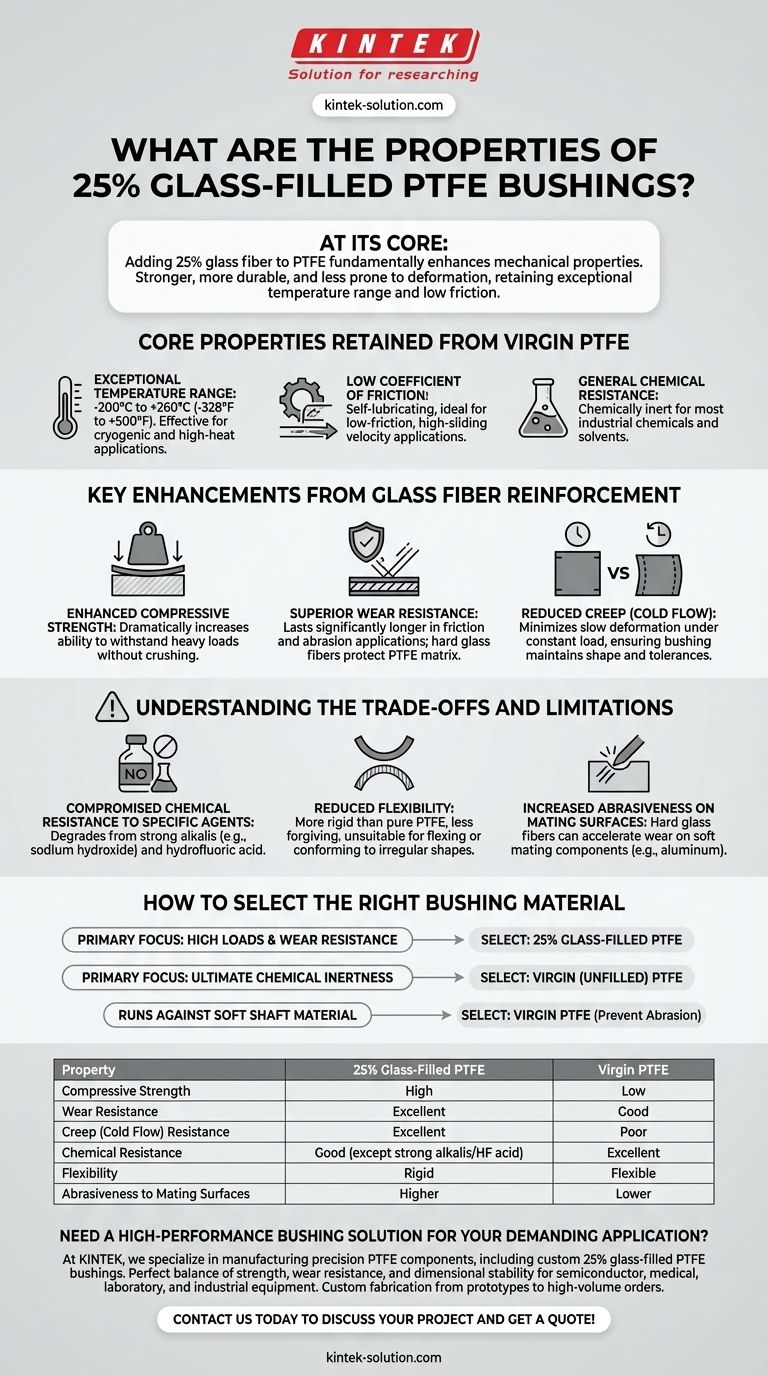

At its core, adding 25% glass fiber to a Polytetrafluoroethylene (PTFE) bushing fundamentally enhances its mechanical properties. This reinforcement makes the material significantly stronger, more durable, and far less prone to deformation under load, while retaining the exceptional temperature range and low-friction characteristics of virgin PTFE.

The decision to use 25% glass-filled PTFE is a strategic trade-off. You gain superior strength, wear resistance, and dimensional stability in exchange for a slight reduction in chemical inertness and flexibility compared to unfilled PTFE.

Core Properties Retained from Virgin PTFE

While glass filler provides significant mechanical improvements, the resulting composite still benefits from the foundational properties that make PTFE a unique engineering material.

### Exceptional Temperature Range

Glass-filled PTFE operates effectively across the same broad temperature spectrum as virgin PTFE, typically from -200°C to +260°C (-328°F to +500°F). This allows it to be used in cryogenic applications as well as high-heat environments.

### Low Coefficient of Friction

The material maintains a very low coefficient of friction. This "slipperiness" is inherent to PTFE and ensures that even with the glass filler, the bushings are self-lubricating and ideal for low-friction, high-sliding velocity applications.

### General Chemical Resistance

For most applications, 25% glass-filled PTFE is considered chemically inert. It resists attack from a wide array of industrial chemicals and solvents, making it a reliable choice for corrosive environments.

Key Enhancements from Glass Fiber Reinforcement

The addition of 25% milled glass fibers is what distinguishes this material, providing a direct upgrade to its performance under physical stress.

### Enhanced Compressive Strength

The glass fibers act as a reinforcing agent, dramatically increasing the material's ability to withstand heavy loads without being crushed. This is a primary reason for selecting it over virgin PTFE in structural roles.

### Superior Wear Resistance

Glass-filled PTFE bushings last significantly longer in applications involving friction and abrasion. The hard glass fibers protect the softer PTFE matrix, reducing wear and extending the service life of the component.

### Reduced Creep (Cold Flow)

Perhaps the most critical improvement is the reduction in creep, also known as cold flow. This is the tendency of pure PTFE to slowly deform over time when under a constant load. The glass fibers provide a stable internal structure that minimizes this deformation, ensuring the bushing maintains its shape and tolerances.

Understanding the Trade-offs and Limitations

No material choice is without compromise. Understanding the limitations of glass-filled PTFE is critical for proper application and avoiding premature failure.

### Compromised Chemical Resistance to Specific Agents

While generally inert, the glass fibers themselves can be attacked by specific, aggressive chemicals. Strong alkalis (like sodium hydroxide) and hydrofluoric acid will degrade the glass filler, compromising the material's integrity. Virgin PTFE should be used in these specific environments.

### Reduced Flexibility

The addition of glass fibers makes the material much more rigid than pure PTFE. It is less forgiving and cannot be used in applications that require the bushing to flex or conform to irregular shapes.

### Increased Abrasiveness on Mating Surfaces

The hard glass fibers can be more abrasive than pure PTFE. When paired with a soft mating surface, such as aluminum or certain plastics, a glass-filled bushing can accelerate wear on the mating component. Material compatibility must be carefully considered.

How to Select the Right Bushing Material

Your application's specific demands should dictate your material choice.

- If your primary focus is high loads and wear resistance: Choose 25% glass-filled PTFE for its superior strength and durability.

- If your primary focus is ultimate chemical inertness: Use virgin (unfilled) PTFE, especially if strong alkalis or hydrofluoric acid are present.

- If your bushing runs against a soft shaft material: Select virgin PTFE to prevent abrasion and premature wear of the mating surface.

Ultimately, understanding these distinct properties empowers you to select the precise material engineered to meet your performance goals.

Summary Table:

| Property | 25% Glass-Filled PTFE | Virgin PTFE |

|---|---|---|

| Compressive Strength | High | Low |

| Wear Resistance | Excellent | Good |

| Creep (Cold Flow) Resistance | Excellent | Poor |

| Chemical Resistance | Good (except strong alkalis/HF acid) | Excellent |

| Flexibility | Rigid | Flexible |

| Abrasiveness to Mating Surfaces | Higher | Lower |

Need a high-performance bushing solution for your demanding application?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom 25% glass-filled PTFE bushings. Our expertise ensures you get the perfect balance of strength, wear resistance, and dimensional stability for industries like semiconductor, medical, laboratory, and industrial equipment.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision to meet your exact specifications.

Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech