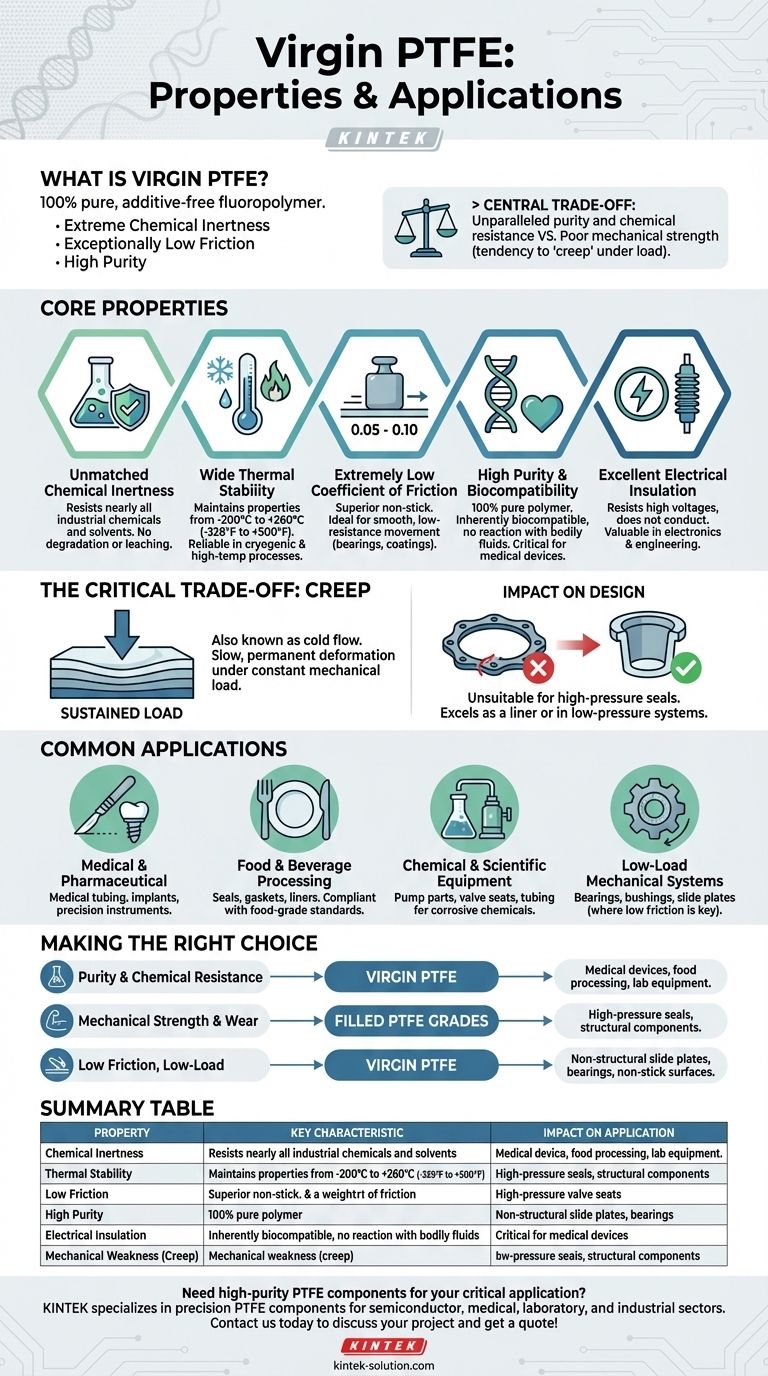

At its core, virgin Polytetrafluoroethylene (PTFE) is a 100% pure, additive-free fluoropolymer. It is distinguished by its extreme chemical inertness, exceptionally low friction, and high purity, making it a default choice for applications in the medical, pharmaceutical, and food processing industries.

While virgin PTFE offers unparalleled chemical resistance and biocompatibility, its defining limitation is poor mechanical strength, specifically its tendency to "creep" or deform under a sustained load. This trade-off between purity and structural integrity is the central factor in its proper application.

Core Properties of Virgin PTFE

Unmatched Chemical Inertness

Virgin PTFE is almost completely inert, resisting nearly all industrial chemicals and solvents. This makes it an ideal material for handling corrosive substances without risk of degradation.

Its high insolubility ensures that it will not break down or leach contaminants into the medium it contains.

Wide Thermal Stability

The material maintains its properties across an exceptionally broad temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This allows it to be used reliably in both cryogenic applications and high-temperature processes without losing its structural integrity or key characteristics.

Extremely Low Coefficient of Friction

With a coefficient of friction between 0.05 and 0.10, virgin PTFE is one of the "slickest" solid materials known. This gives it superior non-stick properties.

This characteristic is crucial for applications requiring smooth, low-resistance movement, such as in certain types of bearings or as a hydrophobic coating.

High Purity and Biocompatibility

Because it is 100% pure polymer with no fillers or additives, virgin PTFE is inherently biocompatible. It does not react with bodily fluids or tissues.

This purity is non-negotiable for medical devices like implants, catheters, and surgical tools, where preventing contamination is critical.

Excellent Electrical Insulation

Virgin PTFE is an outstanding electrical insulator. It resists high voltages and does not conduct electricity, making it a valuable component in electrical engineering and electronics.

Understanding the Critical Trade-off: Creep

The Concept of "Creep" or Cold Flow

The primary mechanical weakness of virgin PTFE is its susceptibility to creep, also known as cold flow.

This is the tendency of the material to slowly and permanently deform when subjected to a sustained mechanical load, even at room temperature.

The Impact on Application Design

This characteristic makes virgin PTFE unsuitable for high-pressure seals or structural components that must bear significant, constant loads.

Under pressure, a virgin PTFE gasket or seal can deform and lose its sealing force over time, leading to potential failure. It excels as a liner or in low-pressure systems.

Why Filled Grades Exist

This limitation is precisely why "filled" or "compounded" grades of PTFE were developed. Adding fillers like glass fiber, carbon, or bronze dramatically improves creep resistance and wear properties, but at the expense of the absolute purity of the virgin material.

Common Applications Driven by Its Properties

Medical and Pharmaceutical

The combination of purity, chemical inertness, and biocompatibility makes virgin PTFE essential for medical tubing, implants, and components for scientific instruments where precision and non-reactivity are paramount.

Food and Beverage Processing

Its non-stick surface and compliance with food-grade standards make it a go-to material for seals, gaskets, and liners in food manufacturing equipment.

Chemical and Scientific Equipment

For components that will be exposed to highly corrosive chemicals, virgin PTFE is used extensively. This includes pump parts, valve seats, chemical-resistant tubing, and manifolds.

Low-Load Mechanical Systems

In applications where low friction is the primary requirement and mechanical loads are minimal, virgin PTFE is used for bearings, bushings, and slide plates.

Making the Right Choice for Your Application

Selecting the right material requires understanding your primary engineering goal.

- If your primary focus is purity and chemical resistance: Virgin PTFE is the definitive choice for applications like medical devices, food processing, or lab equipment where contamination is not an option.

- If your primary focus is mechanical strength and wear resistance: You must consider filled PTFE grades, as virgin PTFE will likely deform and fail under significant mechanical stress or high-pressure loads.

- If your primary focus is low friction in a low-load environment: Virgin PTFE is an excellent and cost-effective material for non-structural slide plates, bearings, and non-stick surfaces.

Ultimately, understanding the trade-off between virgin PTFE's exceptional purity and its inherent mechanical weakness is the key to successful material selection.

Summary Table:

| Property | Key Characteristic | Impact on Application |

|---|---|---|

| Chemical Inertness | Resists nearly all chemicals and solvents | Ideal for handling corrosive substances without degradation |

| Thermal Stability | Stable from -200°C to +260°C | Reliable in cryogenic and high-temperature processes |

| Low Friction | Coefficient of friction: 0.05 - 0.10 | Superior non-stick properties for bearings and coatings |

| High Purity | 100% pure polymer, no fillers | Biocompatible for medical devices and food processing |

| Electrical Insulation | Outstanding electrical insulator | Valuable for electronics and high-voltage applications |

| Mechanical Weakness (Creep) | Deforms under sustained load | Unsuitable for high-pressure seals; excels as a liner |

Need high-purity PTFE components for your critical application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your parts meet the exacting standards for purity and chemical resistance that virgin PTFE demands.

Whether you require prototypes or high-volume production, we deliver solutions that prioritize precision and performance. Let us help you select the right material for your needs.

Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key applications of the PTFE bottle? Ensure Chemical Safety and Sample Purity

- What are the main advantages of PTFE as a material for laboratory bottles? Superior Chemical & Thermal Resistance

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- How does the PTFE bottle perform in terms of chemical resistance? Unmatched Protection for Harsh Chemicals

- How does the composition of PTFE differ from other plastics? Unlocking Its Unique Chemical & Friction Properties