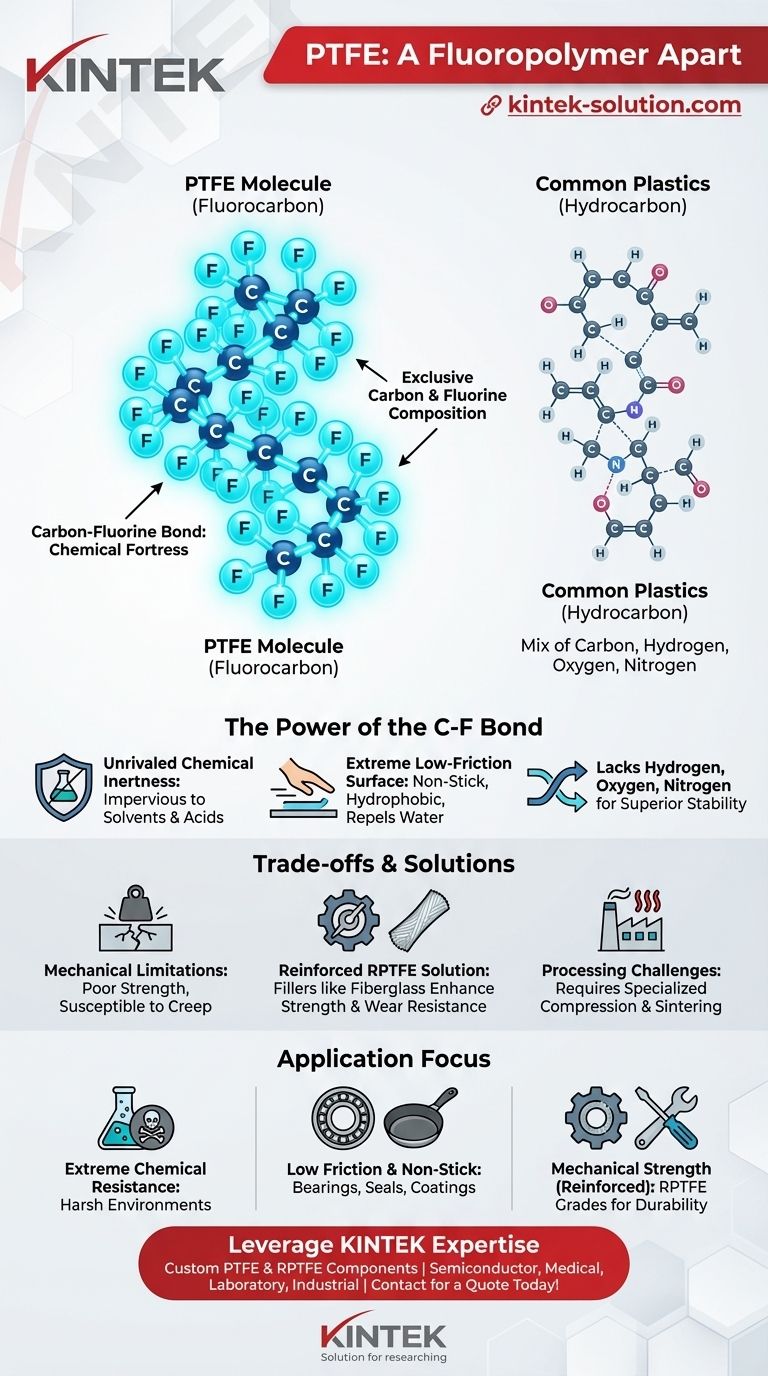

At its core, PTFE's composition is fundamentally different from other plastics due to its exclusive use of carbon and fluorine. While most common polymers are organic compounds built from a mix of carbon, hydrogen, oxygen, and nitrogen, PTFE is a fluoropolymer consisting solely of a carbon backbone completely sheathed in fluorine atoms. This unique and powerful carbon-fluorine bond is the source of its remarkable and highly specialized properties.

The critical takeaway is not just what PTFE is made of, but why it matters. The extreme strength and stability of the carbon-fluorine bond give PTFE its defining characteristics: unparalleled chemical inertness and an exceptionally low coefficient of friction, setting it apart from virtually all other plastics.

The Carbon-Fluorine Bond: A Chemical Fortress

The properties that make PTFE so distinct are a direct result of its simple but powerful molecular structure. It's less about what's in it and more about how those components are bonded together.

### A Protective Fluorine Sheath

The PTFE molecule consists of a long chain of carbon atoms. Each carbon atom is bonded to two fluorine atoms, creating a structure where the carbon backbone is completely encased by a tight, dense sheath of fluorine.

This fluorine sheath acts like a protective armor for the vulnerable carbon chain within.

### Unrivaled Chemical Inertness

The bond between carbon and fluorine is exceptionally strong and stable. This makes the molecule non-reactive and highly resistant to attack from other chemicals.

PTFE is virtually impervious to almost all industrial solvents, acids, and corrosive substances. In terms of pure chemical resistance, it significantly outperforms even other high-performance plastics like PEEK and Nylon.

### Extreme Low-Friction Surface

This same fluorine-rich surface also results in very low intermolecular forces. In practical terms, this means other substances have a very hard time sticking to it.

This is why PTFE has an exceptionally low coefficient of friction, lower than materials like Acetal or Polycarbonate. It's also hydrophobic, meaning it repels water completely.

What PTFE Lacks: The Impact of Simplicity

Just as important as what PTFE contains is what it lacks compared to other polymers. This chemical simplicity is a key part of its stability.

### The Absence of Hydrogen

Most plastics are hydrocarbons, containing weaker carbon-hydrogen (C-H) bonds. These bonds are potential sites for chemical reactions. As a fluorocarbon, PTFE has no such weak points, contributing to its superior stability.

### No Oxygen, Nitrogen, or Other Elements

The absence of other reactive elements like oxygen or nitrogen further enhances its inertness. Its simple, two-element composition leaves very few avenues for chemical interaction.

Understanding the Trade-offs

While its chemical properties are extraordinary, PTFE's unique composition also leads to significant mechanical limitations. No material is perfect, and understanding these trade-offs is crucial.

### Relatively Poor Mechanical Strength

Virgin, unfilled PTFE is a relatively soft material. It has poor wear resistance, is susceptible to "creep" (deformation under load), and lacks the rigidity of many engineering plastics.

### The Role of Reinforcing Fillers

To overcome these mechanical weaknesses, PTFE is often reinforced with filler materials. A common example is RPTFE, which is PTFE reinforced with fiberglass (typically 15-25%).

These fillers dramatically improve strength, wear resistance, and dimensional stability, though they can slightly alter the chemical resistance and coefficient of friction.

### Processing Challenges

PTFE has a very high melting point and extremely high melt viscosity. This makes it impossible to process using conventional techniques like injection molding that are common for other thermoplastics. It requires specialized compression and sintering processes, which can increase manufacturing complexity and cost.

Making the Right Choice for Your Application

Selecting the right material requires matching its inherent properties to your primary goal.

- If your primary focus is extreme chemical resistance: PTFE is the definitive choice for operating in harsh chemical environments where other plastics would fail.

- If your primary focus is low friction and non-stick performance: PTFE is the ideal solution for applications like high-performance bearings, seals, gaskets, and non-stick coatings.

- If your primary focus is mechanical strength or wear resistance: Virgin PTFE is likely unsuitable; you should consider a reinforced grade like RPTFE or a different engineering plastic altogether.

Understanding PTFE's core carbon-fluorine composition empowers you to leverage its unique strengths with precision.

Summary Table:

| Property | PTFE (Virgin) | Common Plastics (e.g., Nylon, PEEK) |

|---|---|---|

| Primary Elements | Carbon & Fluorine only | Carbon, Hydrogen, Oxygen, Nitrogen |

| Chemical Resistance | Unparalleled (inert to most solvents/acids) | Good to Very Good |

| Coefficient of Friction | Exceptionally Low | Moderate to Low |

| Mechanical Strength/Wear | Poor (requires fillers like glass) | Good to Excellent |

| Key Advantage | Chemical Inertness & Non-Stick | Mechanical & Thermal Performance |

Leverage PTFE's Unique Properties for Your Application

Understanding the fundamental composition of PTFE is the first step. Applying this knowledge to solve your specific challenge is the next. The experts at KINTEK are here to help you navigate the trade-offs and select the perfect PTFE formulation—from virgin for ultimate chemical purity to reinforced RPTFE for enhanced strength and wear resistance.

We specialize in the precision manufacturing of custom PTFE components (seals, liners, labware, and more) for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or high-volume production, we deliver the material expertise and manufacturing excellence to ensure your project's success.

Contact us today to discuss your requirements and get a quote! #ContactForm

Visual Guide

Related Products

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the advantages of PTFE coating? Achieve Superior Low Friction & Chemical Resistance

- What are the different types of Teflon coatings and their features? Choose the Right Fluoropolymer for Your Application

- What are the common applications of PTFE in aggressive chemical environments? Ensure Reliability and Safety

- What benefits do ePTFE membranes and laminates provide to device manufacturers? Solve the Venting vs. Contamination Paradox

- Why is PTFE's chemical inertness important for aerospace applications? Ensuring Safety & Reliability in Demanding Environments

- What are the potential causes of color changes in reprocessed PTFE? A Guide to Performance and Purity

- What is the temperature range for PTFE usage? Master -200°C to +260°C for Extreme Applications

- What certifications does the manufacturer of PTFE products have? Ensure Quality with ISO 9001 Certification