In short, PTFE is difficult to process because of its inherent material properties. The primary challenges are its tendency to permanently deform under pressure (a phenomenon known as creep or cold flow), its lack of elastic memory, and its low mechanical strength, all of which demand specialized handling and design considerations.

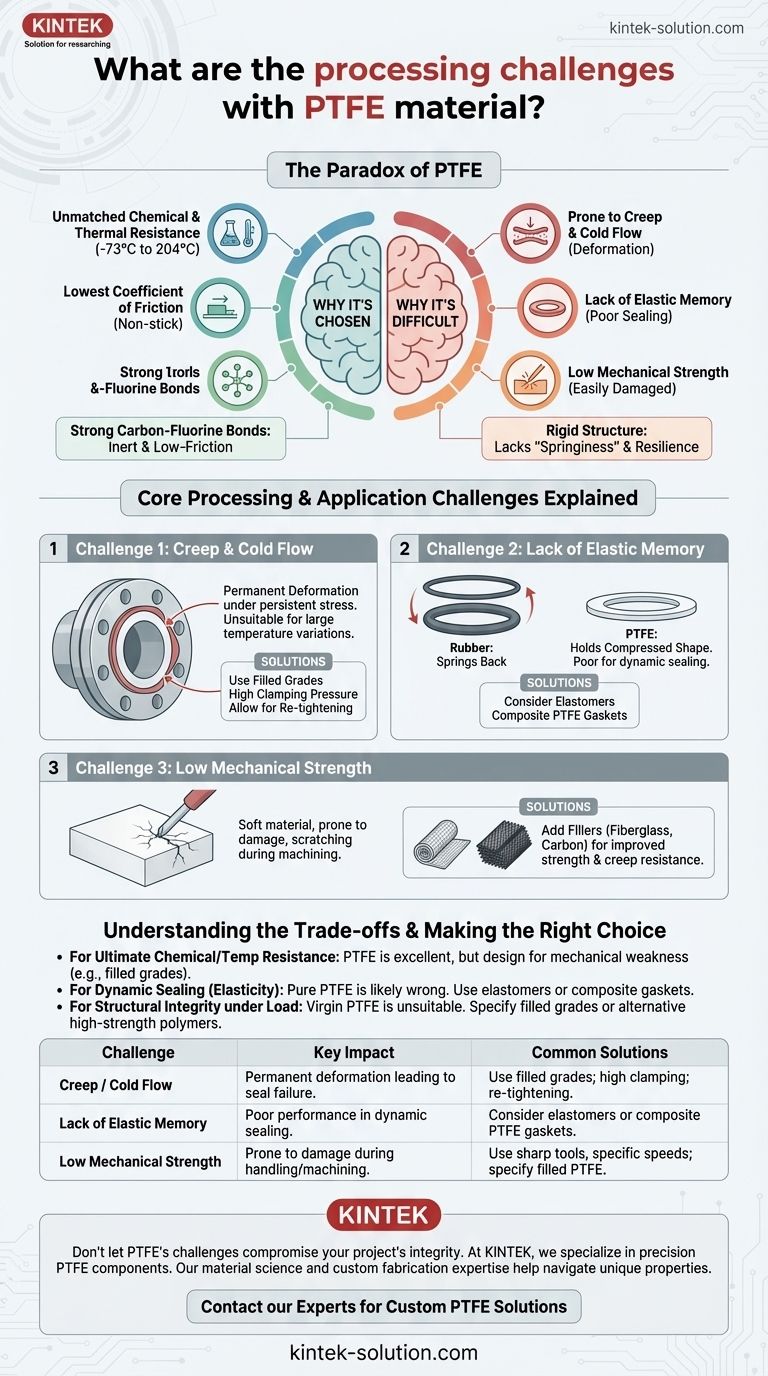

The core challenge of working with PTFE is a paradox: the very molecular structure that gives it exceptional chemical resistance and a low-friction surface also prevents it from behaving like a typical, resilient plastic, making it prone to deformation.

The Paradox of PTFE: Why an Ideal Material is So Difficult

To understand the processing challenges, you must first appreciate why engineers choose PTFE despite the difficulties. It possesses a combination of properties that are nearly unmatched by other polymers.

Unmatched Chemical and Thermal Resistance

PTFE is virtually inert, resisting attack from almost all acids, alkalis, and solvents. It also operates reliably across a vast temperature range, typically from -73°C to 204°C (-100°F to 450°F).

The Lowest Coefficient of Friction

Known for its famous non-stick surface, PTFE has one of the lowest coefficients of friction of any solid material. This makes it ideal for bearings, valve components, and low-friction coatings.

The Molecular Root of the Problem

These benefits stem from the strong carbon-fluorine bonds in its molecular structure. However, this same structure results in a material that is rigid and lacks the "springiness" or elasticity common in other plastics.

Core Processing and Application Challenges Explained

The unique properties of PTFE directly lead to three significant challenges that affect every stage from fabrication to final application.

Challenge 1: Creep and Cold Flow

Creep, or cold flow, is the tendency of a solid material to move slowly or deform permanently under the influence of persistent mechanical stress. PTFE is highly susceptible to this.

Under pressure from a clamp, bolt, or flange, a PTFE component will slowly deform and will not return to its original shape. This makes it unsuitable for applications with large temperature variations, as thermal expansion and contraction can exacerbate the flow.

Challenge 2: Lack of Elastic Memory

Related to cold flow is PTFE's poor elasticity. Unlike a rubber O-ring that can be compressed and will spring back, a PTFE gasket that is deformed will hold its new, compressed shape.

This lack of "memory" makes it a poor choice for dynamic sealing applications where the seal must adapt to changing pressures or movements.

Challenge 3: Low Mechanical Strength

Virgin PTFE is a relatively soft material. This makes it prone to damage, scratching, or marring during machining and handling.

To counteract this weakness, fillers like fiberglass, carbon, or graphite are often added. These fillers dramatically improve the material's strength and resistance to creep, though they may slightly alter its other properties.

Understanding the Trade-offs

Choosing PTFE requires a clear-eyed view of its limitations. Ignoring them leads to component failure.

Sealing and Gasket Design

Because of cold flow, PTFE gaskets can loosen over time, leading to leaks. They require specific flange designs and high-pressure clamping to maintain a reliable seal, and even then, periodic re-tightening may be necessary.

Machining and Fabrication

The softness of PTFE means that standard machining practices can fail. Sharp tools, specific cutting speeds, and careful handling are required to achieve tight tolerances without damaging the final part.

Fastening and Assembly

When using PTFE washers or insulators, the material's tendency to creep can cause bolted joints to lose their preload over time. This requires careful torque specifications and an understanding that the joint may not remain as tight as one assembled with metal components.

Making the Right Choice for Your Application

Your final decision must be based on a clear understanding of the application's primary demand.

- If your primary focus is ultimate chemical inertness or temperature resistance: PTFE is an excellent choice, but you must design the assembly to accommodate its mechanical weaknesses, potentially by using filled grades or specialized clamping mechanisms.

- If your primary focus is a dynamic seal that requires elasticity: Pure PTFE is likely the wrong material. You should consider elastomers or specially engineered composite PTFE gaskets.

- If your primary focus is structural integrity under mechanical load: Virgin PTFE is unsuitable. You must specify a filled grade of PTFE or select a different high-strength engineering polymer.

Ultimately, successfully using PTFE is about leveraging its incredible resistance properties while actively designing around its inherent mechanical weaknesses.

Summary Table:

| Challenge | Key Impact | Common Solutions |

|---|---|---|

| Creep / Cold Flow | Permanent deformation under load, leading to seal failure. | Use filled grades; design for high clamping pressure; allow for re-tightening. |

| Lack of Elastic Memory | Poor performance in dynamic sealing applications. | Consider elastomers or composite PTFE gaskets for dynamic seals. |

| Low Mechanical Strength | Prone to damage during machining and handling. | Use sharp tools, specific speeds; specify filled PTFE grades (glass, carbon). |

Don't let PTFE's challenges compromise your project's integrity.

At KINTEK, we specialize in manufacturing precision PTFE components—from seals and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in material science and custom fabrication allows us to help you navigate PTFE's unique properties, whether you need prototypes or high-volume orders.

Contact our experts today to discuss how we can provide a PTFE solution tailored to your specific application and performance requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance