The primary benefits of PTFE Teflon washers stem from their unique combination of exceptional chemical resistance, broad temperature stability, extremely low friction, and excellent electrical insulation. These core properties make them a highly versatile and reliable component for sealing, spacing, and reducing wear in some of the most demanding industrial applications imaginable.

PTFE Teflon washers are not just simple components; they are engineering problem-solvers for extreme environments. Their value lies in their ability to maintain structural integrity and performance where nearly all other plastic or rubber materials would degrade and fail.

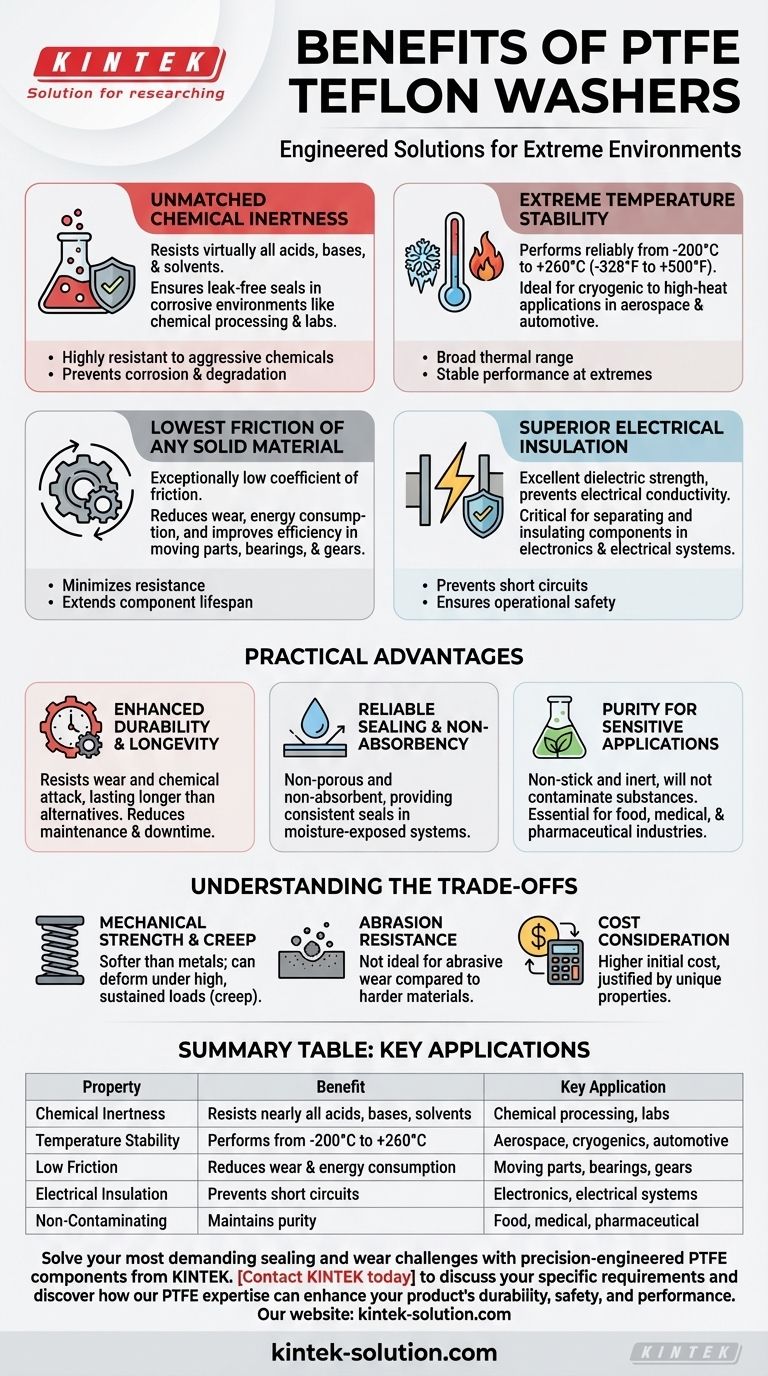

The Core Properties Driving PTFE's Versatility

To understand why these washers are used in everything from aerospace to food processing, we must first examine their fundamental material properties. Each characteristic directly solves a common engineering challenge.

Unmatched Chemical Inertness

PTFE is virtually inert and does not react with the vast majority of industrial chemicals, including aggressive acids, bases, and solvents.

This property is critical in chemical processing plants and laboratories, ensuring a reliable, leak-free seal in corrosive environments where other materials would quickly corrode and fail.

Extreme Temperature Stability

PTFE washers perform reliably across an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This allows them to be used in both cryogenic applications and high-temperature machinery, a level of versatility that is rare for a single material. This makes them invaluable in automotive engines and aerospace systems.

The Lowest Friction of Any Solid Material

The coefficient of friction for PTFE is one of the lowest recorded for any solid material, meaning surfaces can slide against it with minimal resistance.

This is highly beneficial in applications with moving parts, such as gears or bearings. It reduces wear and tear, improves operational efficiency, and lowers the energy required to operate machinery.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with high dielectric strength, meaning it does not conduct electricity.

This property makes it a default choice for separating and insulating components in electronics and electrical systems, preventing short circuits and ensuring operational safety.

From Material Properties to Practical Advantages

These core properties translate directly into tangible benefits that enhance the durability, safety, and efficiency of the systems they are part of.

Enhanced Durability and Longevity

Because PTFE resists chemical attack and wear from friction, these washers last significantly longer than many alternatives. This durability reduces the need for frequent replacements, lowering maintenance costs and system downtime.

Reliable Sealing and Non-Absorbency

PTFE is non-absorbent and non-porous. This ensures that it will not swell or degrade when exposed to moisture, providing a consistent and reliable seal in plumbing, HVAC, and fluid-handling systems.

Purity for Sensitive Applications

The non-stick, inert nature of PTFE means it will not contaminate the substances it comes into contact with. This is an absolute requirement in the food processing, medical, and pharmaceutical industries, where purity is paramount.

Understanding the Trade-offs

While its benefits are significant, PTFE is not the ideal solution for every situation. Objectivity requires acknowledging its limitations.

Mechanical Strength and Creep

PTFE is a relatively soft material compared to metals. Under high, sustained mechanical loads, it can be susceptible to "creep," which is a slow deformation over time. This must be a consideration in high-pressure structural applications.

Abrasion Resistance

While its low friction prevents adhesive wear, PTFE is not as resistant to abrasive wear (scraping or grinding from hard particles) as harder materials like nylon or metal. It is best suited for smooth, sliding contact.

Cost Consideration

PTFE washers are often more expensive than common alternatives like rubber or nylon. Their use is best justified in applications where their unique chemical, thermal, or frictional properties are a specific requirement.

Making the Right Choice for Your Application

Selecting the right material is about matching its properties to your primary goal. Use PTFE washers when your design demands performance that commodity materials cannot deliver.

- If your primary focus is sealing in corrosive environments: PTFE's chemical inertness provides the most reliable barrier against nearly all industrial chemicals.

- If your primary focus is reducing wear in moving parts: The exceptionally low friction coefficient minimizes energy loss and dramatically extends the lifespan of components.

- If your primary focus is performance across extreme temperatures: PTFE's stability from cryogenic lows to high heat makes it one of the few viable non-metallic options.

- If your primary focus is electrical isolation: Its outstanding dielectric properties make it a default choice for insulating components in sensitive electrical systems.

By understanding these core benefits and their practical trade-offs, you can confidently specify PTFE washers to solve your most demanding engineering challenges.

Summary Table:

| Property | Benefit | Key Application |

|---|---|---|

| Chemical Inertness | Resists nearly all acids, bases, solvents | Chemical processing, labs |

| Temperature Stability | Performs from -200°C to +260°C | Aerospace, cryogenics, automotive |

| Low Friction | Reduces wear & energy consumption | Moving parts, bearings, gears |

| Electrical Insulation | Prevents short circuits | Electronics, electrical systems |

| Non-Contaminating | Maintains purity | Food, medical, pharmaceutical |

Solve your most demanding sealing and wear challenges with precision-engineered PTFE components from KINTEK.

Our PTFE washers, seals, liners, and labware are manufactured to the highest standards for industries where failure is not an option—including semiconductor, medical, laboratory, and specialized industrial applications. We offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact solution for your extreme environment needs.

Contact KINTEK today to discuss your specific requirements and discover how our PTFE expertise can enhance your product's durability, safety, and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments