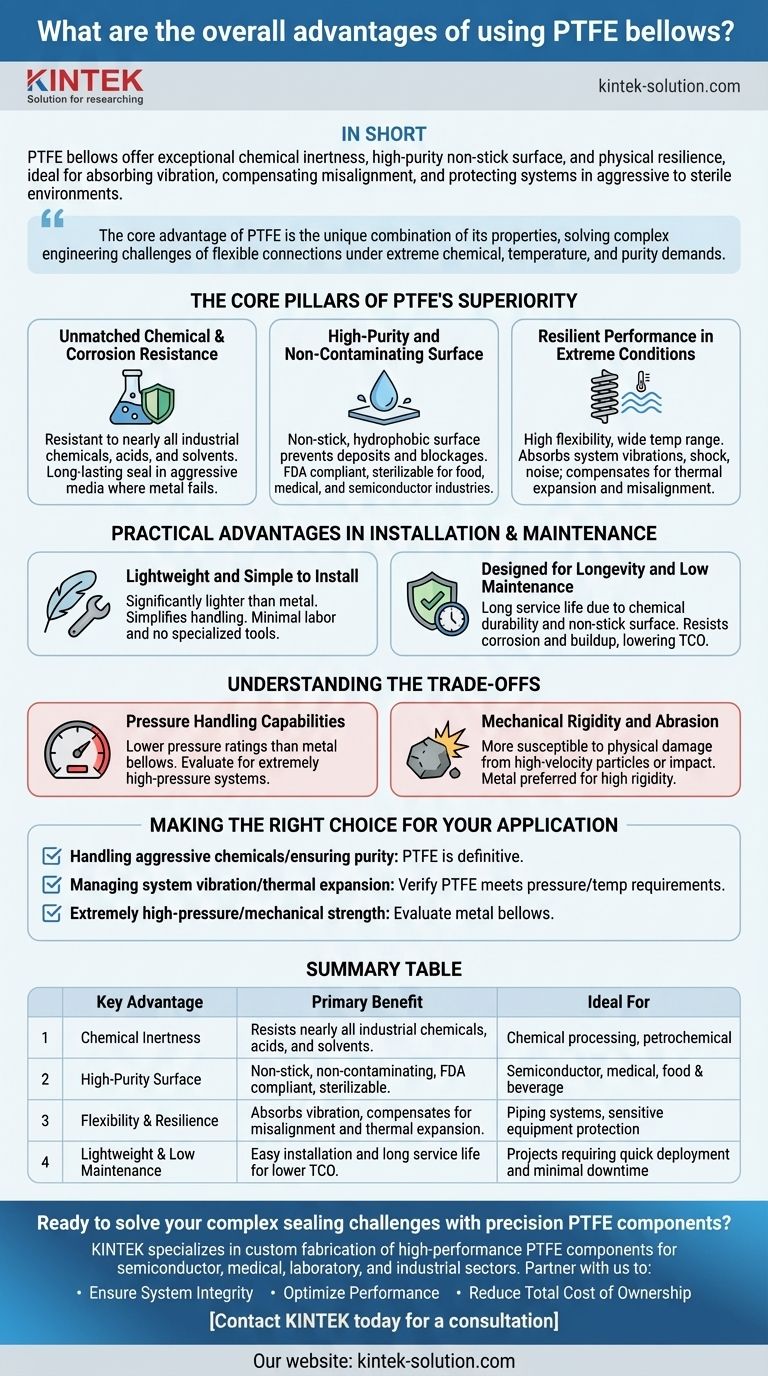

In short, PTFE bellows are chosen for their exceptional chemical inertness, high-purity non-stick surface, and physical resilience. These properties make them a superior solution for absorbing vibration, compensating for misalignment, and protecting systems in applications ranging from aggressive chemical processing to sterile semiconductor and food production environments.

The core advantage of PTFE is not just one feature, but the unique combination of its properties. It solves the complex engineering challenge of requiring a flexible connection that can simultaneously withstand extreme chemicals, wide temperature ranges, and high-purity demands where most other materials would quickly fail.

The Core Pillars of PTFE's Superiority

Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer, and bellows made from this material inherit its powerful characteristics. Understanding these pillars is key to knowing when and why to specify them.

Unmatched Chemical & Corrosion Resistance

PTFE is one of the most chemically inert materials known. It is resistant to nearly all industrial chemicals, acids, and solvents.

This makes PTFE bellows the default choice for systems handling aggressive media, such as in petrochemical pipelines or chemical manufacturing. Where metal bellows would corrode and fail, PTFE provides a long-lasting, reliable seal.

High-Purity and Non-Contaminating Surface

The surface of PTFE is inherently non-stick, or hydrophobic. It is designed to repel other materials, preventing media from sticking to or being trapped within the convolutions of the bellows.

This non-adhesive property is critical for two reasons. First, it ensures efficient and consistent fluid flow by preventing deposits and blockages. Second, it is vital for high-purity applications, as it minimizes contamination. This, combined with FDA compliance and suitability for sterilization, makes it ideal for food, medical, and semiconductor industries.

Resilient Performance in Extreme Conditions

PTFE bellows exhibit both high flexibility and a wide operating temperature range. They effectively absorb system vibrations, shock, and noise.

This flexibility also allows them to compensate for thermal expansion and contraction in pipe systems, as well as minor pipe misalignment. By absorbing these stresses, PTFE bellows protect more sensitive or rigid components in the system, increasing overall reliability.

Practical Advantages in Installation & Maintenance

Beyond its material science benefits, PTFE offers tangible advantages in deployment and long-term ownership. These factors directly impact project timelines and operational budgets.

Lightweight and Simple to Install

Compared to their metal counterparts, PTFE bellows are significantly lighter. This simplifies handling, transportation, and the installation process itself.

Installation often requires minimal labor and no specialized tools, reducing both the time and cost associated with system assembly.

Designed for Longevity and Low Maintenance

The combination of chemical durability and a non-stick surface results in an exceptionally long service life. Because they resist both corrosion and deposit buildup, PTFE bellows require far less maintenance and replacement than other options.

This translates directly to a lower total cost of ownership (TCO) by minimizing downtime, labor costs, and the expense of replacement parts.

Understanding the Trade-offs

No material is perfect for every scenario. To make an informed decision, you must also understand the limitations of PTFE compared to alternatives like metal bellows.

Pressure Handling Capabilities

While suitable for many applications, PTFE bellows generally have lower pressure ratings than stainless steel or other metal alloy bellows. For extremely high-pressure systems, a metal bellow might be the necessary choice.

Mechanical Rigidity and Abrasion

PTFE is a flexible polymer, not a rigid metal. It is more susceptible to physical damage from high-velocity abrasive particles within the media or from external impact. In environments where high rigidity or puncture resistance is paramount, metal remains the standard.

Making the Right Choice for Your Application

Your final decision must be aligned with the primary demand of your specific engineering goal.

- If your primary focus is handling aggressive chemicals or ensuring absolute purity: PTFE is the definitive choice due to its near-universal inertness and clean, non-stick surface.

- If your primary focus is managing system vibration and thermal expansion: PTFE's flexibility offers excellent absorption, but you must first verify it meets your system's pressure and temperature requirements.

- If your primary focus is extremely high-pressure containment or mechanical strength: You should evaluate metal bellows, as they are specifically designed to excel in these demanding structural applications.

Ultimately, selecting PTFE bellows is a strategic decision to ensure system integrity and longevity in demanding operational environments.

Summary Table:

| Key Advantage | Primary Benefit | Ideal For |

|---|---|---|

| Chemical Inertness | Resists nearly all industrial chemicals, acids, and solvents. | Chemical processing, petrochemical |

| High-Purity Surface | Non-stick, non-contaminating, FDA compliant, and sterilizable. | Semiconductor, medical, food & beverage |

| Flexibility & Resilience | Absorbs vibration, compensates for misalignment and thermal expansion. | Piping systems, sensitive equipment protection |

| Lightweight & Low Maintenance | Easy installation and long service life for lower total cost of ownership. | Projects requiring quick deployment and minimal downtime |

Ready to solve your complex sealing challenges with precision PTFE components?

KINTEK specializes in the custom fabrication of high-performance PTFE components, including bellows, seals, liners, and labware. We serve the demanding needs of the semiconductor, medical, laboratory, and industrial sectors.

Partner with us to:

- Ensure System Integrity: Leverage our PTFE expertise to protect your equipment from aggressive chemicals and ensure product purity.

- Optimize Performance: Get custom-designed components that precisely meet your application's requirements for temperature, pressure, and flexibility.

- Reduce Total Cost of Ownership: Benefit from durable, long-lasting parts that minimize downtime and maintenance.

We handle everything from initial prototypes to high-volume production, prioritizing precision and quality.

Contact KINTEK today for a consultation and let our experts help you select or design the perfect PTFE solution for your application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry