To be precise, Polytetrafluoroethylene (PTFE) is considered non-toxic because it is physiologically inert and biocompatible. This means it is extremely unreactive and does not cause an adverse response when it comes into contact with living tissue. Its unique molecular structure makes it stable, insoluble, and unable to be metabolized or absorbed by the body.

The non-toxic nature of PTFE is not a single characteristic but an outcome of its fundamental properties: extreme chemical resistance, thermal stability, and an inability to react with or be broken down by biological systems.

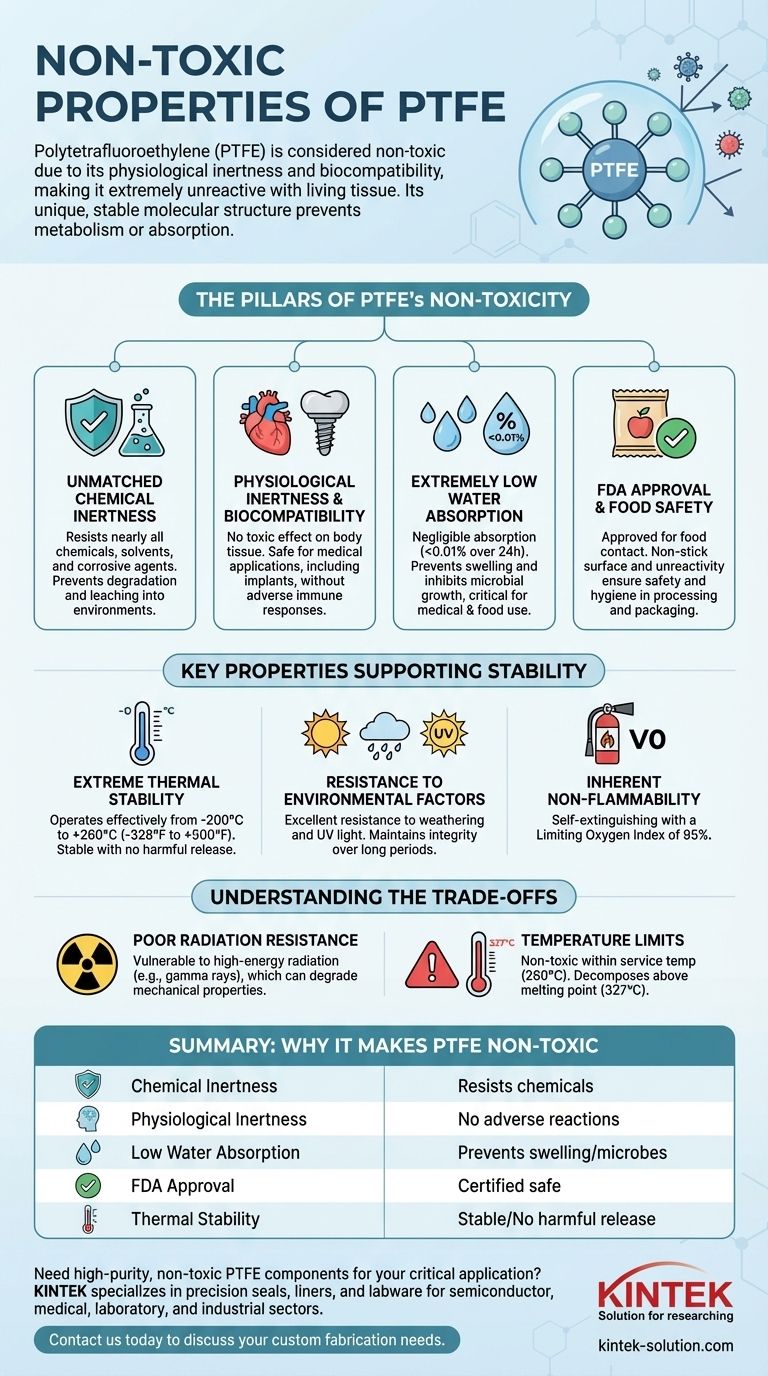

The Pillars of PTFE's Non-Toxicity

The safety of PTFE for sensitive applications stems from several core properties that work in concert. Understanding these properties is key to appreciating why it is trusted in fields from medicine to food processing.

Unmatched Chemical Inertness

PTFE is renowned for its resistance to nearly all chemicals, solvents, and corrosive agents.

This high inertness means the material will not degrade or break down, preventing it from leaching substances into its surrounding environment, whether that is a chemical pipeline or the human body.

Physiological Inertness and Biocompatibility

These two terms are central to PTFE's non-toxic profile. Physiological inertness means it has no toxic or irritating effect when in contact with body tissue or fluids.

Biocompatibility is the next step, meaning it can be used in medical applications without causing rejection, inflammation, or other adverse immune responses. This is why it is a material of choice for artificial blood vessels and other implants.

Extremely Low Water Absorption

PTFE absorbs a negligible amount of water, with a rating of just 0.01% over a 24-hour period.

This property prevents the material from swelling or degrading in moist environments. It also makes the surface inhospitable to microbial growth, a critical factor for both medical and food-grade applications.

FDA Approval and Food Safety

As a direct result of its inertness and stability, PTFE is approved by the FDA for food contact applications.

Its non-stick surface, combined with its inability to react with food products, ensures that it is a safe and hygienic choice for processing and packaging.

Key Properties Supporting Its Stability

The non-toxic characteristics of PTFE are underpinned by a broader set of physical properties that ensure it remains stable and safe across a wide range of conditions.

Extreme Thermal Stability

PTFE operates effectively across an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F).

Within this vast range, the material remains stable and does not decompose, ensuring it doesn't release harmful substances during normal use in either cryogenic or high-heat applications.

Resistance to Environmental Factors

PTFE demonstrates excellent resistance to weathering and ultraviolet (UV) light.

Unlike many other plastics that can become brittle or break down with environmental exposure, PTFE maintains its integrity, ensuring its safety and performance over long periods.

Inherent Non-Flammability

With a limiting oxygen index of 95% and a flammability rating of V0, PTFE is exceptionally difficult to ignite and is self-extinguishing. This adds another layer to its overall safety profile in industrial and electrical applications.

Understanding the Trade-offs

While PTFE is exceptionally stable, no material is without limitations. An objective evaluation requires acknowledging the conditions under which its properties change.

Poor Radiation Resistance

The primary environmental weakness of PTFE is its poor resistance to high-energy radiation, such as gamma rays.

Under significant radiation exposure, the polymer chains can be broken, leading to a degradation of its mechanical properties. This makes it unsuitable for certain applications in the nuclear industry or for radiation-based sterilization.

The Context of Temperature Limits

The non-toxic properties of PTFE are defined within its specified service temperature of up to 260°C (500°F). Exceeding its melting point of 327°C (621°F) will cause the material to decompose. It is critical to operate within the established engineering limits to ensure its stability.

How This Applies to Your Application

Your choice of material should always align with the specific demands of your project.

- If your primary focus is medical implants or direct biological contact: Its physiological inertness and biocompatibility are the most critical properties, ensuring patient safety.

- If your primary focus is food processing or pharmaceuticals: Its FDA approval, chemical inertness, and low water absorption guarantee product purity and prevent contamination.

- If your primary focus is industrial use in harsh environments: Its thermal stability and resistance to chemicals and weathering are key to its reliable and safe performance.

Ultimately, understanding that PTFE's safety is a function of its fundamental stability allows you to select and implement it with confidence.

Summary Table:

| Property | Why It Makes PTFE Non-Toxic |

|---|---|

| Chemical Inertness | Resists nearly all chemicals; prevents leaching and degradation. |

| Physiological Inertness & Biocompatibility | Does not cause adverse reactions with body tissue; safe for implants. |

| Low Water Absorption (<0.01%) | Prevents swelling and microbial growth; ideal for medical and food use. |

| FDA Approval | Certified safe for direct and indirect food contact applications. |

| Thermal Stability (-200°C to +260°C) | Remains stable without decomposing or releasing harmful substances. |

Need high-purity, non-toxic PTFE components for your critical application?

KINTEK specializes in manufacturing precision PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our commitment to quality ensures your components deliver the safety and performance you require.

Contact us today to discuss your custom fabrication needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability