At its core, the non-stick property of Polytetrafluoroethylene (PTFE) arises from its unique molecular structure, featuring incredibly strong carbon-fluorine bonds. This creates an extremely low-friction, chemically inert surface to which very few substances will adhere, making it famous for cookware coatings and indispensable across a vast range of industrial, medical, and electrical applications.

PTFE's value extends far beyond the non-stick pan. Its non-stick nature is a symptom of its more fundamental properties—extreme chemical resistance and one of the lowest coefficients of friction of any solid—which solve critical challenges in the most demanding environments.

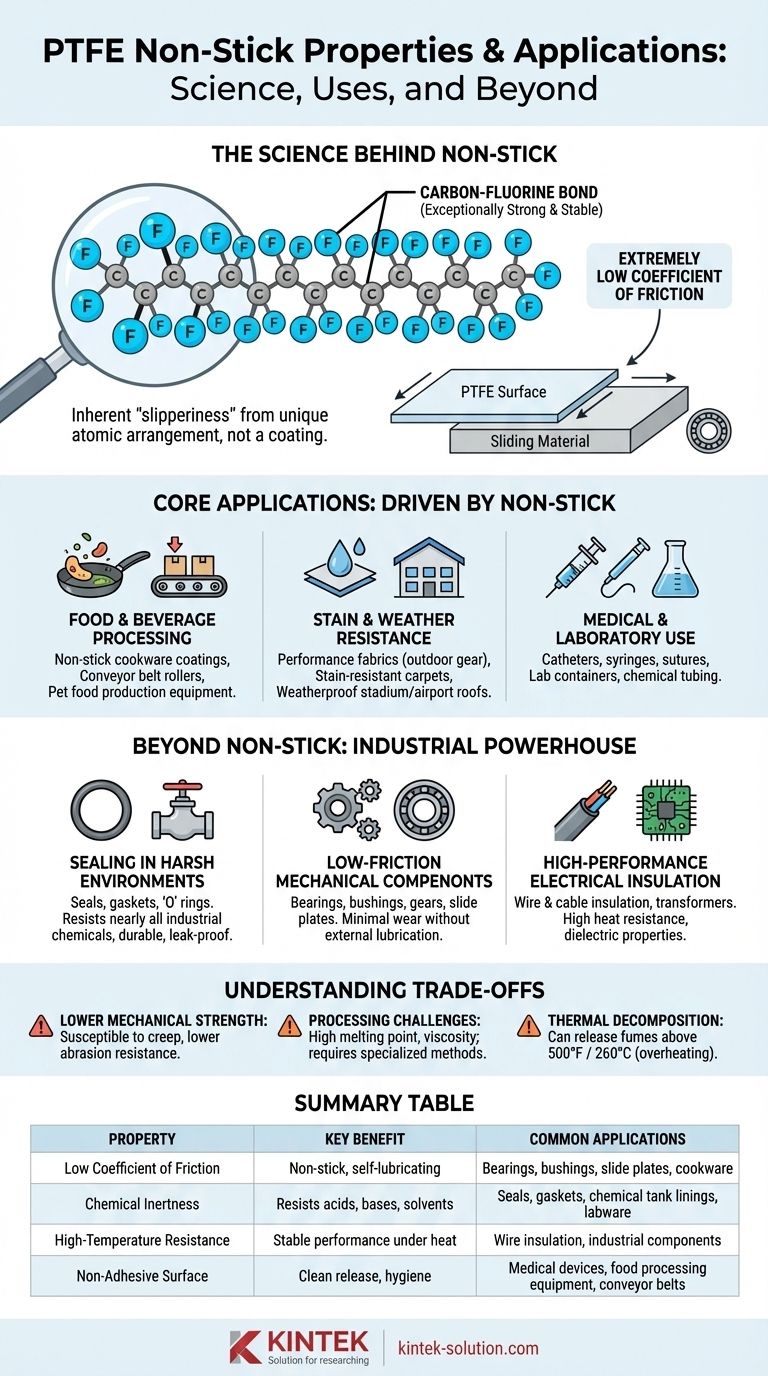

The Science Behind the Non-Stick Surface

To understand PTFE's applications, you must first understand its fundamental material properties. Its famous "slipperiness" is not a coating but an intrinsic quality of the material itself.

The Power of Fluorine

The PTFE molecule is composed of a long chain of carbon atoms, each completely sheathed by larger fluorine atoms. The carbon-fluorine bond is exceptionally strong and stable.

This stable atomic arrangement creates a surface that is highly non-reactive. It doesn't have available electrons to form bonds with other materials, which is why things just don't stick to it.

An Extremely Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This means it offers exceptionally low resistance to sliding motion.

This inherent slipperiness is the technical reason for its non-stick performance, whether it's preventing food from burning onto a pan or ensuring smooth movement in a mechanical bearing.

Core Applications Driven by Non-Stick Properties

While its applications are diverse, a significant number leverage its non-stick and repellent characteristics directly.

Food and Beverage Processing

The most well-known application is in non-stick coatings for cookware, such as frying pans and muffin pans, to prevent food adhesion.

In industrial settings, this property improves hygiene and efficiency. It's used on conveyor belt rollers and in equipment for pet food production where clean, rapid release of materials is critical.

Stain and Weather Resistance

The same property that repels food also repels water and stains. PTFE is used in performance fabrics like outdoor rain gear and as a protective coating for stain-resistant carpets.

For large-scale infrastructure, it serves as a durable, self-cleaning, and weatherproof coating for the roofs of stadiums and airports.

Medical and Laboratory Use

In medical and lab environments, preventing adhesion is critical for safety and accuracy. PTFE is used for catheters, syringes, and sutures to ensure smooth, non-reactive passage.

Its non-stick surface also makes it an ideal material for lab containers and chemical tubing, preventing cross-contamination and material loss.

Beyond Non-Stick: Industrial Powerhouse Applications

The same root properties that make PTFE non-stick—low friction and chemical inertness—also make it a premier material for heavy industry.

Sealing in Harsh Environments

PTFE is widely used for seals, gaskets, and 'O' rings, especially in the chemical industry.

Its ability to resist nearly all industrial chemicals and solvents, combined with its low-friction surface, creates durable, leak-proof seals for valves, pumps, and pipes.

Low-Friction Mechanical Components

In machinery, reducing friction is key to longevity and efficiency. PTFE is a common choice for bearings, bushings, gears, and slide plates.

These components allow parts to move smoothly against each other with minimal wear, even without external lubrication, particularly in the oil and gas industry.

High-Performance Electrical Insulation

PTFE is an excellent electrical insulator with high heat resistance. This makes it a critical material for insulating wires and cables, especially in demanding aerospace and computing applications.

It is also used in insulated transformers and other components where electrical and thermal stability are non-negotiable.

Chemical Containment and Transport

Due to its extreme chemical inertness, PTFE is used to create linings for chemical tanks, vessels, and pipes. This protects the structural material from corrosion by aggressive acids and bases.

Understanding the Trade-offs

No material is perfect. To use PTFE effectively, it is critical to understand its limitations.

Lower Mechanical Strength

Compared to other engineering plastics, PTFE is relatively soft. It can be susceptible to creep (deformation under constant load) and has lower abrasion resistance.

Processing Challenges

PTFE has a very high melting point and viscosity, making it difficult to process using conventional techniques like injection molding. It often requires specialized compression and sintering methods.

Thermal Decomposition

While it has excellent heat resistance for most applications, PTFE can begin to decompose at extremely high temperatures (above 500°F / 260°C), releasing fumes. This is a primary safety concern for severely overheated cookware.

Making the Right Choice for Your Goal

Selecting a material depends entirely on the problem you need to solve. PTFE is a versatile tool, but its best use is highly specific.

- If your primary focus is clean release and hygiene: PTFE's non-stick surface is unmatched for applications in food processing, medical devices, and consumer cookware.

- If your primary focus is chemical resistance: Its inertness makes it the default choice for seals, gaskets, and linings in aggressive chemical environments.

- If your primary focus is reducing mechanical friction: Its low coefficient of friction is ideal for self-lubricating bearings, bushings, and other wear components.

- If your primary focus is electrical and thermal stability: Its dielectric properties make it a top-tier material for high-performance wire and cable insulation.

Ultimately, PTFE's celebrated non-stick quality is just the most visible benefit of a uniquely powerful and versatile engineering material.

Summary Table:

| Property | Key Benefit | Common Applications |

|---|---|---|

| Low Coefficient of Friction | Non-stick, self-lubricating | Bearings, bushings, slide plates, cookware |

| Chemical Inertness | Resists acids, bases, solvents | Seals, gaskets, chemical tank linings, labware |

| High-Temperature Resistance | Stable performance under heat | Wire insulation, industrial components |

| Non-Adhesive Surface | Clean release, hygiene | Medical devices, food processing equipment, conveyor belts |

Need high-performance PTFE components tailored to your exact needs?

At KINTEK, we specialize in manufacturing precision PTFE parts—from custom seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures a solution that leverages PTFE's full potential for your application.

Contact our experts today to discuss your project and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability