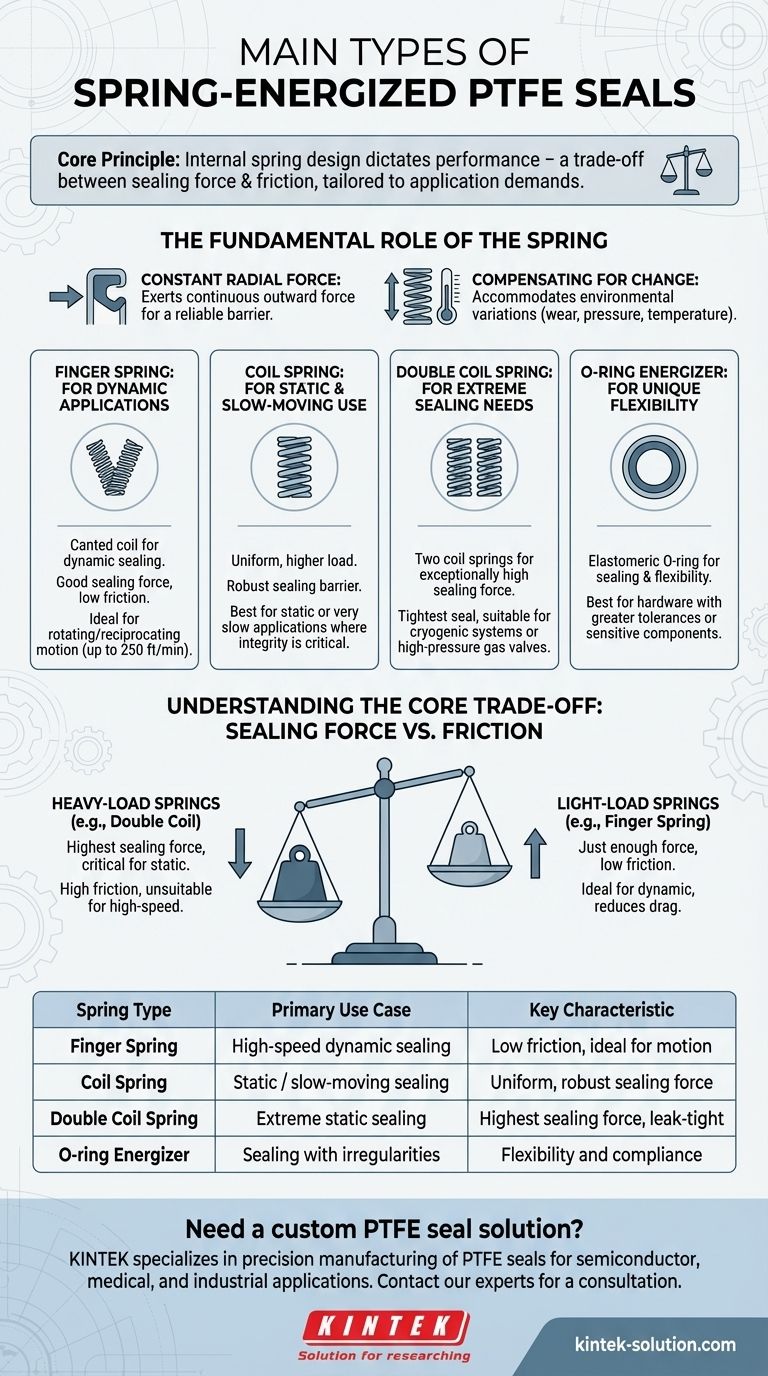

When selecting a spring-energized PTFE seal, the primary distinction lies in the type of internal spring used to generate the sealing force. The four main types are the finger spring, the coil spring, the double coil spring, and the O-ring energizer. Each is engineered for a different balance of friction, sealing integrity, and operational conditions, making the spring choice a critical design decision.

The core principle to understand is that the internal spring design directly dictates the seal's performance. The choice is a deliberate trade-off between sealing force and friction, tailored to specific application demands like high-speed motion, static pressure, or cryogenic temperatures.

The Fundamental Role of the Spring

Before comparing types, it's crucial to understand why the spring exists. It provides the consistent, mechanical force needed for the seal to function effectively.

Constant Radial Force

The spring exerts a continuous outward force on the PTFE seal jacket. This pressure forces the seal lips against the mating hardware, creating a reliable sealing barrier.

Compensating for Change

This spring force is vital for accommodating variations in the operating environment. It compensates for material wear, pressure fluctuations, and dimensional changes caused by temperature shifts, ensuring the seal remains engaged.

A Breakdown of Each Spring Type

The geometry and material of the spring define its load characteristics and, therefore, its ideal use case.

Finger Spring: For Dynamic Applications

The finger spring, often a V-shaped or U-shaped canted coil, is the standard for dynamic sealing. Its design provides a good balance of sealing force with relatively low friction.

This makes it ideal for rotating or reciprocating applications with surface speeds up to 250 ft/min, where minimizing drag and wear is essential.

Coil Spring: For Static and Slow-Moving Use

A helical coil spring provides a more uniform and typically higher load on the seal lips compared to a finger spring. This increased force creates a more robust sealing barrier.

It is best suited for static (non-moving) or very slow dynamic applications where sealing integrity is more critical than low friction.

Double Coil Spring: For Extreme Sealing Needs

As the name suggests, this design uses two coil springs to generate an even higher sealing force. This configuration creates an exceptionally tight and reliable seal.

Its primary use is in demanding static applications where leakage is unacceptable, such as in cryogenic systems or high-pressure gas valves.

O-ring Energizer: For Unique Flexibility

In some cases, a traditional metal spring is not suitable. An elastomeric O-ring can be used as the energizer instead, providing a balance of sealing and flexibility.

This type is often chosen for applications where the hardware has greater-than-normal tolerances or where a metal spring might damage sensitive components.

Understanding the Core Trade-off: Sealing Force vs. Friction

The choice between spring types ultimately comes down to managing one critical trade-off. A stronger spring creates a better seal but also generates more friction and wear.

Heavy-Load Springs

Springs like the double coil are considered heavy-load. They provide the tightest possible seal, which is necessary for critical static applications.

The downside is significantly higher friction, making them unsuitable for high-speed dynamic systems where they would quickly generate heat and wear out.

Light-Load Springs

The finger spring is a prime example of a light-load spring. It is engineered to provide just enough force to seal effectively while keeping friction to a minimum.

This reduces operational drag and extends the service life of the seal in dynamic equipment, even if it doesn't provide the absolute leak-tightness of a heavy-load spring.

Matching the Seal to Your Application

To make a definitive choice, align the spring's characteristics with your primary operational goal.

- If your primary focus is high-speed dynamic sealing: Choose a Finger Spring to minimize friction and wear.

- If your primary focus is maximum sealing in a static environment: Choose a Double Coil Spring for the highest sealing force, especially in cryogenic or high-pressure gas applications.

- If your primary focus is general-purpose static or slow-moving sealing: A standard Coil Spring offers a reliable balance of strong sealing force.

- If your primary focus is sealing with hardware irregularities: Consider an O-ring Energized seal for its superior flexibility and compliance.

Ultimately, selecting the correct spring energizer is the key to unlocking the full performance potential of a PTFE seal for your specific engineering challenge.

Summary Table:

| Spring Type | Primary Use Case | Key Characteristic |

|---|---|---|

| Finger Spring | High-speed dynamic sealing | Low friction, ideal for motion |

| Coil Spring | Static / slow-moving sealing | Uniform, robust sealing force |

| Double Coil Spring | Extreme static sealing (cryogenic, high-pressure) | Highest sealing force, leak-tight |

| O-ring Energizer | Sealing with hardware irregularities | Flexibility and compliance |

Need a custom PTFE seal solution for your semiconductor, medical, or industrial application?

At KINTEK, we specialize in precision manufacturing of PTFE components like seals, liners, and labware. We can help you select or custom-fabricate the perfect spring-energized seal—from prototypes to high-volume orders—to optimize performance, minimize friction, and ensure sealing integrity in your specific operating conditions.

Contact our experts today for a consultation and let us provide a sealing solution tailored to your unique engineering challenge.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key properties of PTFE material used in the spacer? Ensure Stability in Harsh Environments

- In which industries are PTFE diaphragms commonly used? For Superior Chemical Resistance and Purity

- How do PTFE coatings prevent component failure? Control Friction and Corrosion for Reliable Performance

- What types of PTFE tri clamp gaskets are available? Choose the Right Seal for Your System

- How does a PTFE liner function in a spherical bearing or rod end? Achieve Maintenance-Free, Self-Lubricating Performance

- What is the importance of torque checks in PTFE butterfly valves? Prevent Leaks & Extend Valve Life

- What are the key properties of PTFE that make it suitable for structural bearings? Unlock Superior Load Support & Movement

- What properties make Teflon sheets useful for industrial applications? Solve Friction, Heat, and Chemical Challenges