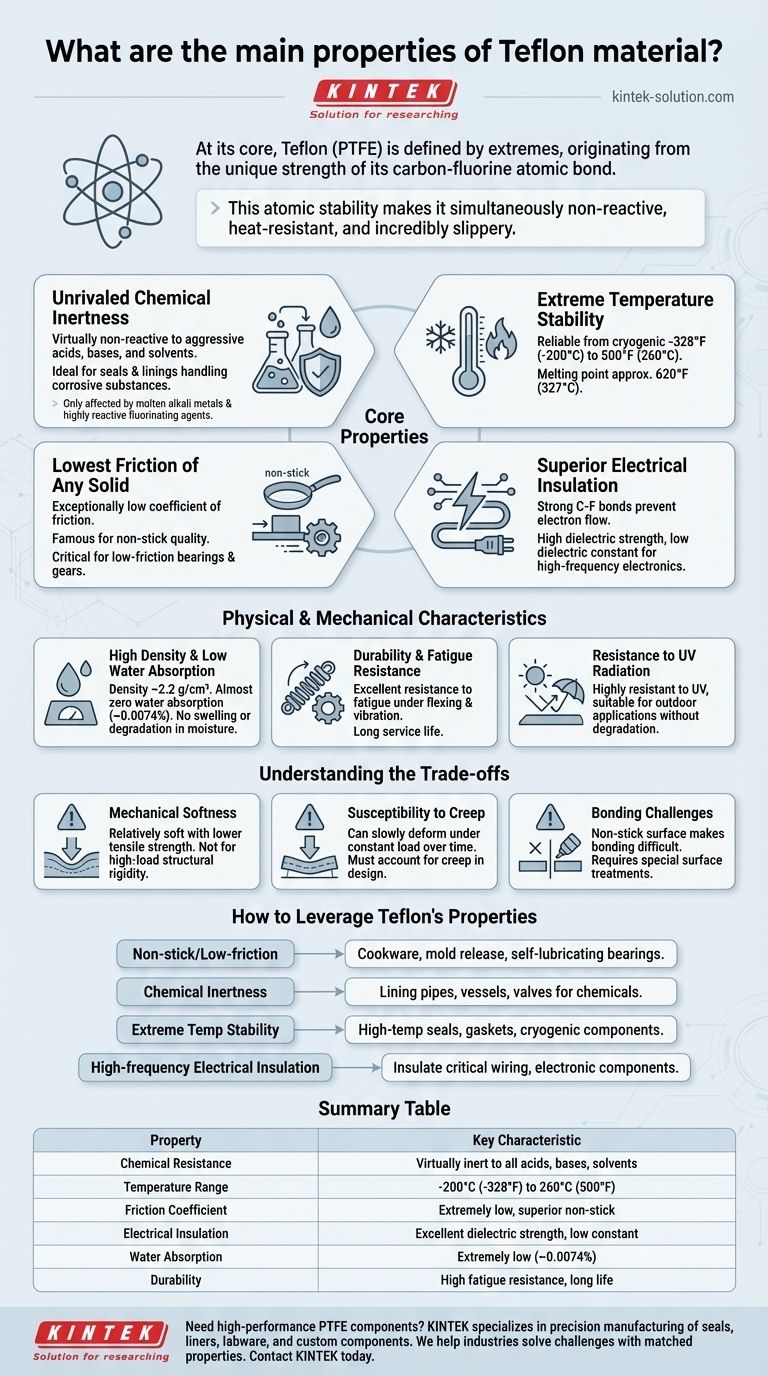

At its core, Teflon is a material defined by extremes. Its most prominent properties are its exceptional chemical inertness, an extremely low coefficient of friction (making it non-stick), and stability across a vast range of temperatures. These are complemented by its excellent electrical insulation capabilities, fatigue resistance, and very low moisture absorption.

The unique strength of the bond between its carbon and fluorine atoms is the source of all of Teflon's remarkable properties. This atomic stability makes it simultaneously non-reactive, heat-resistant, and incredibly slippery, creating a material uniquely suited for the most demanding environments.

The Core Properties Explained

To understand why Teflon (the brand name for Polytetrafluoroethylene, or PTFE) is so widely used, we must look at how its primary characteristics function.

Unrivaled Chemical Inertness

Teflon is virtually non-reactive to all chemicals, including aggressive acids, bases, and solvents. This makes it an ideal material for seals, linings, and containers that handle corrosive substances.

The only known materials that can chemically affect it are molten alkali metals and highly reactive fluorinating agents.

Extreme Temperature Stability

This material performs reliably across an exceptionally wide temperature spectrum. It remains stable and functional from cryogenic temperatures as low as -328°F (-200°C) up to 500°F (260°C).

Its melting point is approximately 600 K or 327°C (620°F), allowing it to withstand applications like non-stick cookware without degrading.

The Lowest Friction of Any Solid

Teflon has one of the lowest coefficients of friction known for any solid material. This is the fundamental reason for its famous non-stick or anti-adhesive quality.

This property is not just for cookware; it is critical for industrial applications like low-friction bearings, gears, and slide plates where minimizing resistance is essential.

Superior Electrical Insulation

The strong carbon-fluorine bonds in Teflon's molecular structure prevent the free flow of electrons, making it an outstanding electrical insulator.

It has a high dielectric strength and a low dielectric constant, making it indispensable for high-frequency electronics, cable insulation, and circuit boards where signal integrity is paramount.

Physical and Mechanical Characteristics

Beyond its primary chemical and thermal properties, Teflon's physical nature contributes to its versatility.

High Density and Low Water Absorption

With a density of approximately 2.2 g/cm³, Teflon is a relatively heavy polymer. Crucially, it has almost zero water absorption (around 0.0074%).

This means it will not swell, deform, or have its properties degraded when used in moist or submerged environments.

Durability and Fatigue Resistance

Teflon exhibits excellent resistance to fatigue, especially under flexing and vibration. This makes it a durable choice for components that must endure repeated mechanical stress over long periods.

Its robust nature also means it is reusable and has a very long service life in many applications.

Resistance to UV Radiation

The material is also highly resistant to ultraviolet (UV) radiation, which can quickly degrade many other polymers. This allows it to be used in outdoor applications without becoming brittle or losing its integrity.

Understanding the Trade-offs

No material is perfect, and being an effective advisor means acknowledging limitations. Teflon's unique properties come with practical trade-offs.

Mechanical Softness

Compared to metals or harder plastics, Teflon is a relatively soft material with lower tensile strength. It is not suitable for high-load structural applications where rigidity is the primary requirement.

Susceptibility to Creep

Under a constant, sustained load (especially at elevated temperatures), Teflon can slowly deform over time. This phenomenon, known as "creep," must be accounted for in the design of seals and bearings.

Bonding Challenges

The very non-stick surface that makes Teflon so useful also makes it extremely difficult to bond to other materials using conventional adhesives. Special surface treatments like chemical etching are required to create a reliable bond.

How to Leverage Teflon's Properties

Your choice to use Teflon should be directly tied to the specific problem you need to solve.

- If your primary focus is a non-stick or low-friction surface: Leverage its incredibly low coefficient of friction for applications like cookware, mold release, or self-lubricating bearings.

- If your primary focus is handling corrosive materials: Utilize its chemical inertness for lining pipes, vessels, and valves in chemical processing or laboratory equipment.

- If your primary focus is performance in extreme temperatures: Rely on its wide thermal stability for creating high-temperature seals, gaskets, or cryogenic components.

- If your primary focus is high-frequency electrical insulation: Choose Teflon for its low dielectric constant and high resistivity to insulate critical wiring and electronic components.

Understanding these core properties allows you to apply Teflon not just for what it is, but for the specific, challenging problems it is uniquely engineered to solve.

Summary Table:

| Property | Key Characteristic |

|---|---|

| Chemical Resistance | Virtually inert to all acids, bases, and solvents |

| Temperature Range | Stable from -200°C (-328°F) to 260°C (500°F) |

| Friction Coefficient | Extremely low, providing superior non-stick properties |

| Electrical Insulation | Excellent dielectric strength and low dielectric constant |

| Water Absorption | Extremely low (~0.0074%), preventing swelling or degradation |

| Durability | High fatigue resistance and long service life |

Need high-performance PTFE components that leverage these properties?

KINTEK specializes in the precision manufacturing of PTFE seals, liners, labware, and custom components. We help industries like semiconductor, medical, and laboratory solve their toughest challenges with materials that offer unmatched chemical resistance, thermal stability, and non-stick performance.

Whether you need a prototype or a high-volume order, our custom fabrication ensures your components are built to last. Contact KINTEB today to discuss your specific application requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications