At its core, an EPDM valve seat is a highly resilient and flexible sealing component made from a synthetic rubber, Ethylene Propylene Diene Monomer. It is overwhelmingly the material of choice for applications involving water, steam, and many general-purpose chemicals due to its excellent durability and sealing capabilities.

The defining characteristic of an EPDM valve seat is its exceptional performance and longevity in water-based systems. While it offers versatility, its critical limitation is poor resistance to petroleum-based oils, hydrocarbon solvents, and greases.

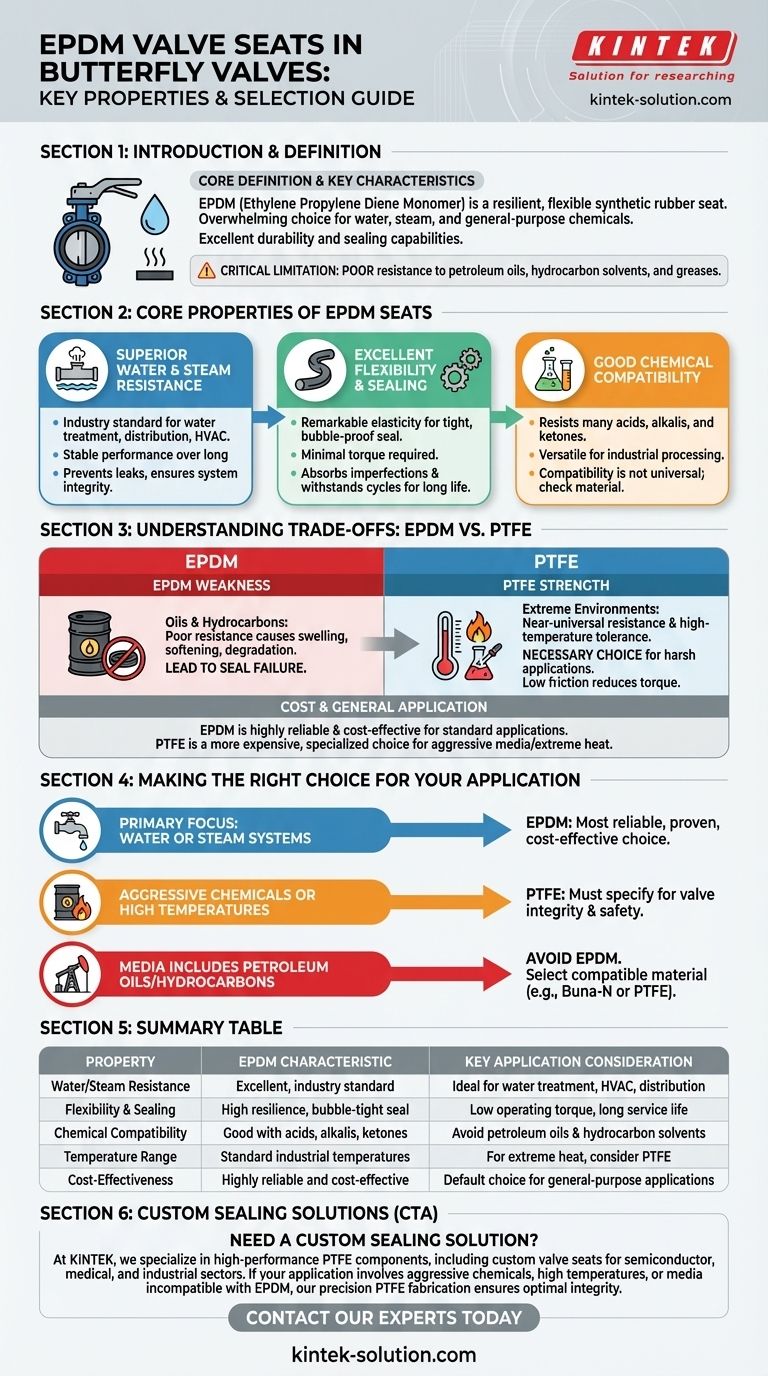

Core Properties of EPDM Seats

Superior Water and Steam Resistance

EPDM's molecular structure makes it highly resistant to degradation from water, saltwater, and steam. This property makes it the industry standard for butterfly valves used in water treatment, distribution, and HVAC systems.

Its performance remains stable and reliable over long periods of exposure, preventing leaks and ensuring system integrity.

Excellent Flexibility and Sealing

As a synthetic rubber, EPDM possesses remarkable flexibility and elasticity. This allows the seat to create a tight, bubble-proof seal against the valve disc with minimal torque.

This resilience also allows the seat to absorb minor imperfections and withstand the repeated stress of opening and closing cycles, contributing to a long service life.

Good Chemical Compatibility

EPDM stands up well against a wide range of chemicals, including most acids, alkalis, and ketones. This makes it a versatile choice for many industrial processing applications.

However, its compatibility is not universal, which is a critical factor in material selection.

Understanding the Trade-offs: EPDM vs. PTFE

The choice of a valve seat material is a critical design decision. To fully understand EPDM's role, it's essential to compare it to another common material, PTFE (Teflon).

EPDM's Weakness: Oils and Hydrocarbons

The most significant limitation of EPDM is its poor resistance to petroleum oils, gasoline, and hydrocarbon solvents. Exposure to these substances will cause the material to swell, soften, and degrade rapidly, leading to seal failure.

In these applications, a material like PTFE or Buna-N is the appropriate choice.

PTFE's Strength: Extreme Environments

PTFE (polytetrafluoroethylene) is known for its near-universal chemical resistance and high-temperature tolerance. It is the necessary choice for harsh applications involving aggressive chemicals or extreme heat where EPDM would fail.

PTFE also has a very low coefficient of friction, which can reduce the torque required to operate the valve.

Cost and General Application

For a vast range of standard industrial applications, EPDM provides a highly reliable and cost-effective sealing solution. It is often the default choice for common valve configurations like wafer and lug-style butterfly valves.

PTFE is typically a more expensive, specialized material chosen specifically to meet the demands of aggressive media or temperature that exceed EPDM's capabilities.

Making the Right Choice for Your Application

Your application's specific media and operating conditions must dictate your material selection.

- If your primary focus is water or steam systems: EPDM is the most reliable, proven, and cost-effective choice for these applications.

- If your system handles aggressive chemicals or high temperatures: You must specify PTFE to ensure valve integrity and system safety.

- If your media includes petroleum oils or hydrocarbon solvents: Avoid EPDM entirely and select a compatible material.

Ultimately, selecting the correct seat material is fundamental to the valve's performance, lifespan, and reliability.

Summary Table:

| Property | EPDM Valve Seat Characteristic | Key Application Consideration |

|---|---|---|

| Water/Steam Resistance | Excellent, industry standard | Ideal for water treatment, HVAC, distribution |

| Flexibility & Sealing | High resilience, bubble-tight seal | Low operating torque, long service life |

| Chemical Compatibility | Good with acids, alkalis, ketones | Avoid petroleum oils & hydrocarbon solvents |

| Temperature Range | Standard industrial temperatures | For extreme heat, consider PTFE |

| Cost-Effectiveness | Highly reliable and cost-effective | Default choice for many general-purpose applications |

Need a custom sealing solution for your valve application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom valve seats and seals, for the semiconductor, medical, laboratory, and industrial sectors. If your application involves aggressive chemicals, high temperatures, or media incompatible with EPDM, our precision PTFE fabrication—from prototypes to high-volume orders—ensures optimal valve integrity and system safety.

Contact our experts today to discuss your specific requirements and discover the right material for reliable, long-lasting performance.

Visual Guide

Related Products

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the key properties of PTFE that benefit bellows and diaphragms? Achieve Unmatched Reliability in Harsh Environments

- What are the main technical features that influence the performance of PTFE diaphragms? Optimize for Durability & Chemical Resistance

- What are PTFE bellows and diaphragms, and why are they important in critical systems?

- What are the key features of PTFE diaphragms? Maximize Performance in Demanding Applications

- What are the common applications of PTFE diaphragms in the Chinese market? Key Uses in Chemical, Pharma & Semiconductor