The performance of a PTFE diaphragm is dictated by a precise combination of its material composition and mechanical design. Its real-world effectiveness in a system is not accidental but a direct result of key technical features. These include the type of PTFE used, its physical thickness, and fundamental mechanical properties like tensile strength and elongation at break.

Selecting the right PTFE diaphragm requires moving beyond the material's baseline benefits to understand how specific technical specifications align with operational demands. The choice between virgin PTFE, filled compounds, or reinforced designs directly impacts the component's durability, chemical resistance, and lifecycle.

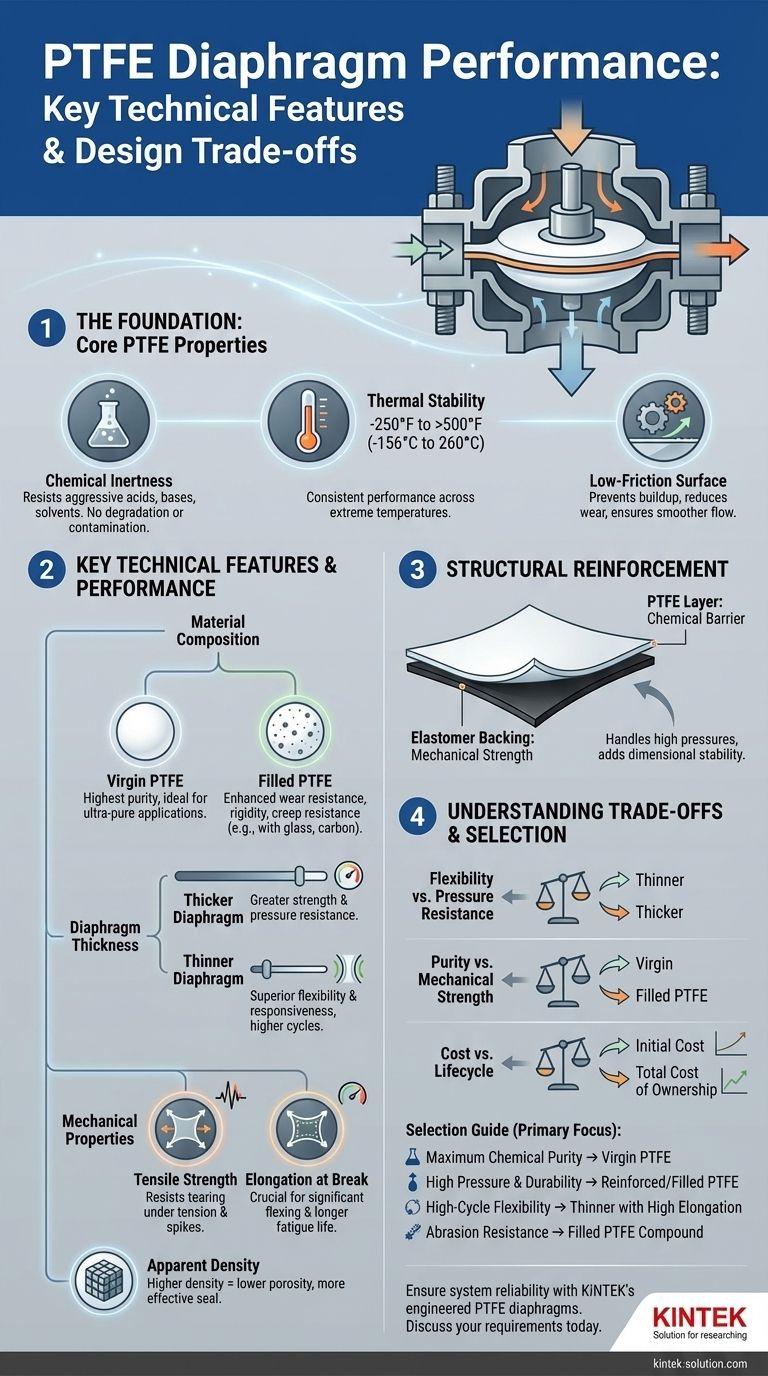

The Foundation: Core Properties of PTFE

Before analyzing specific diaphragm features, it's essential to understand why Polytetrafluoroethylene (PTFE) is the material of choice for demanding applications. Its inherent molecular structure gives it a unique set of advantages.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, including aggressive acids, bases, solvents, and oxidizers. This property ensures the diaphragm will not degrade or contaminate the process media, providing a reliable barrier.

Extreme Thermal Stability

This material maintains its integrity and performance across a vast temperature range, typically from -250°F to over 500°F (-156°C to 260°C). This allows for consistent operation in systems with significant thermal cycling.

Low-Friction, Non-Stick Surface

PTFE has one of the lowest coefficients of friction of any solid material. This non-adhesive surface prevents material buildup, reduces wear on moving parts, ensures smoother flow control, and minimizes the risk of contamination.

Key Technical Features That Define Performance

While all PTFE diaphragms share core benefits, their performance under specific pressures, temperatures, and mechanical stresses is determined by the following design and material features.

Material Composition: Virgin vs. Filled PTFE

Virgin PTFE is pure, unfilled material, offering the highest level of chemical purity and inertness. It is the ideal choice for pharmaceutical, food-grade, or ultra-pure chemical applications.

Filled PTFE incorporates additives like glass, carbon, or graphite into the base material. These fillers significantly enhance specific mechanical properties such as wear resistance, rigidity, and resistance to "creep" (deformation under load), though they may slightly alter chemical compatibility.

Diaphragm Thickness

Thickness is a primary factor in a diaphragm's ability to withstand pressure. A thicker diaphragm provides greater strength and pressure resistance but sacrifices some flexibility. A thinner diaphragm offers superior flexibility and responsiveness, which is critical for high-cycle applications.

Tensile Strength and Elongation

Tensile strength measures the diaphragm's ability to resist tearing or breaking under tension. A higher value indicates a more robust material capable of handling pressure spikes and mechanical stress.

Elongation at break defines how much the material can stretch before failing. High elongation is crucial for applications requiring significant flexing and movement, contributing to a longer fatigue life.

Apparent Density

The density of the finished PTFE material is an indicator of its quality and consolidation during manufacturing. A higher apparent density typically correlates with lower porosity and permeability, ensuring a more effective and durable seal.

The Role of Structural Reinforcement

For applications involving high pressures or the need for absolute dimensional stability, a pure PTFE diaphragm may be bonded to a more rigid backing material.

Why Reinforce a Diaphragm?

Reinforcement, often with a rubber or elastomer backing, provides the mechanical strength to handle high pressures that would otherwise deform or extrude a standalone PTFE layer. The PTFE layer continues to serve as the critical chemical barrier, while the backing provides the structural muscle.

Impact on Performance

A reinforced diaphragm combines the best of both materials: PTFE's universal chemical resistance and the elastomer's strength and resilience. This composite structure significantly increases the diaphragm's pressure rating and overall durability.

Understanding the Trade-offs

Selecting the optimal diaphragm involves balancing competing performance characteristics. There is no single "best" option for all scenarios.

Flexibility vs. Pressure Resistance

The most common trade-off is between diaphragm thickness and flexibility. Increasing thickness for higher pressure handling will inevitably reduce the diaphragm's ability to flex, potentially shortening its life in high-cycle applications.

Chemical Purity vs. Mechanical Strength

Choosing between virgin and filled PTFE is another critical decision. While virgin PTFE offers unparalleled chemical purity, adding fillers to enhance wear resistance or reduce creep can be essential for demanding mechanical applications. You must ensure the chosen filler is compatible with your process media.

Cost vs. Lifecycle

More complex designs, such as multi-layer reinforced or specially filled diaphragms, carry a higher initial cost. However, this investment often results in a significantly longer service life, reduced downtime, and greater system reliability, leading to a lower total cost of ownership.

Selecting the Right Diaphragm for Your Application

Your final choice must be a deliberate decision based on the primary demands of your system.

- If your primary focus is maximum chemical purity and inertness: Choose a diaphragm made from 100% virgin PTFE.

- If your primary focus is high pressure and mechanical durability: Select a thicker, elastomer-backed diaphragm, potentially using a filled PTFE for added rigidity.

- If your primary focus is high-cycle flexibility and responsiveness: Prioritize a thinner diaphragm with high elongation properties, ensuring it still meets pressure requirements.

- If your primary focus is resisting abrasive media or wear: Specify a filled PTFE compound engineered specifically for improved mechanical toughness.

Ultimately, a detailed analysis of these technical features against your specific operational demands is the key to ensuring system reliability and performance.

Summary Table:

| Feature | Impact on Performance |

|---|---|

| Material Composition | Virgin PTFE for purity; filled PTFE for wear resistance/rigidity. |

| Diaphragm Thickness | Thicker for pressure resistance; thinner for flexibility. |

| Tensile Strength | Higher strength resists tearing under tension and pressure spikes. |

| Elongation at Break | Higher elongation allows for more flexing, improving fatigue life. |

| Structural Reinforcement | Elastomer backing adds strength for high-pressure applications. |

Ensure your system's reliability with a PTFE diaphragm engineered for your exact needs.

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including custom diaphragms for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical trade-offs between chemical resistance, pressure handling, flexibility, and lifecycle costs.

Our experts will work with you to select the ideal material—from virgin to filled compounds—and design, whether standalone or reinforced, to maximize your application's performance and durability.

Contact us today to discuss your requirements and receive a quote: Get in Touch

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries