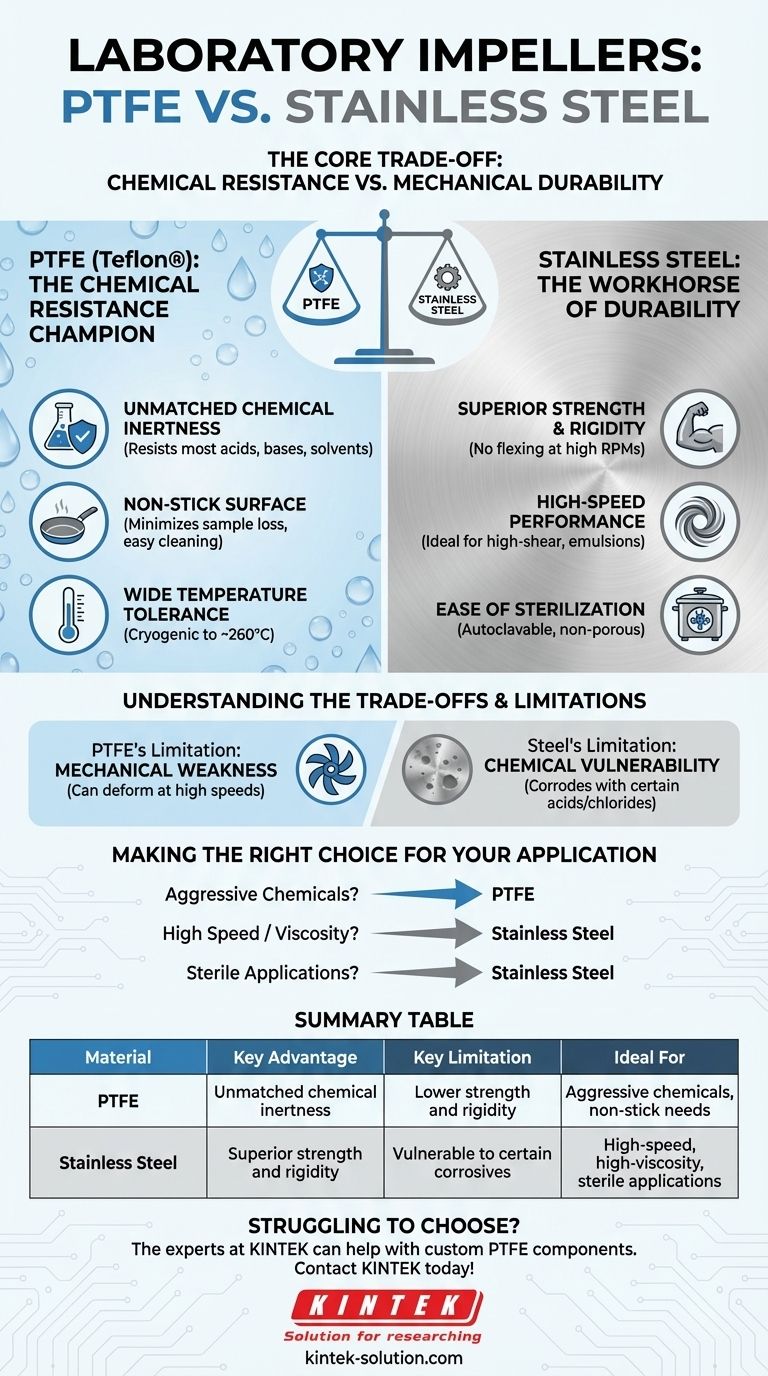

In laboratory settings, the two dominant materials for impellers are PTFE (polytetrafluoroethylene) and stainless steel. This prevalence is not based on cost or availability, but on a critical trade-off between chemical resistance and mechanical durability. The correct choice depends entirely on the specific demands of your application, from the corrosiveness of your reagents to the viscosity of your mixture.

The decision between PTFE and stainless steel is a direct trade-off between chemical inertness and structural integrity. PTFE offers unparalleled resistance to corrosive chemicals, while stainless steel provides the superior strength and rigidity required for high-speed or high-viscosity applications.

The Case for PTFE: The Chemical Resistance Champion

Polytetrafluoroethylene, commonly known by the trade name Teflon®, is a fluoropolymer prized for its unique chemical properties. It is the default choice when sample purity and equipment longevity in harsh chemical environments are the primary concerns.

Unmatched Chemical Inertness

PTFE is virtually inert and does not react with the vast majority of chemicals, including strong acids, bases, and aggressive organic solvents. This property is crucial for preventing contamination of the sample and degradation of the impeller itself.

Non-Stick Surface

Its famously low coefficient of friction creates a non-stick surface. This minimizes the amount of material that adheres to the impeller during mixing, which is particularly useful for viscous or sticky substances.

Wide Temperature Tolerance

PTFE performs reliably across a broad temperature range, typically from cryogenic levels up to approximately 260°C (500°F), accommodating most common laboratory heating and cooling protocols.

The Case for Stainless Steel: The Workhorse of Durability

When mechanical stress, high rotational speeds, or sterile conditions are required, stainless steel is the superior material. Its physical properties provide performance that polymers cannot match.

Superior Strength and Rigidity

Stainless steel is exceptionally strong and rigid. It will not flex, warp, or "walk" up the shaft at high RPMs, ensuring consistent and efficient mixing, especially in highly viscous media where significant force is required.

High-Speed Performance

The rigidity of stainless steel is essential for creating high-shear environments. This is critical for applications like creating fine emulsions, homogenizing samples, or reducing particle size.

Ease of Sterilization

Stainless steel's non-porous surface is easily cleaned and can be reliably sterilized using methods like autoclaving or dry heat. This makes it the standard for biological, pharmaceutical, and cell culture applications where sterility is non-negotiable.

Understanding the Trade-offs and Limitations

Choosing the wrong material can compromise your experiment. Acknowledging the inherent limitations of each option is key to making an informed decision.

PTFE's Mechanical Weakness

The primary drawback of PTFE is its relative softness and flexibility. At high speeds, a PTFE impeller can deform, leading to inefficient mixing. In viscous solutions, it may even flex enough to scrape against the vessel walls.

Stainless Steel's Chemical Vulnerability

While highly resistant to corrosion, stainless steel is not completely inert. Certain grades can be attacked by strong halogenated acids (like hydrochloric acid), chlorides, or other highly corrosive agents, leading to pitting and potential leaching of metal ions into the sample.

Cleaning and Wear

Over time, the surface of PTFE can become scratched or porous, making it more difficult to clean thoroughly compared to polished stainless steel. Conversely, a steel impeller can cause abrasion to a glass vessel if contact is made, whereas a PTFE impeller is far less likely to cause damage.

Making the Right Choice for Your Application

Selecting the correct impeller material is a foundational step for ensuring repeatable and accurate results. Use your primary experimental goal as your guide.

- If your primary focus is aggressive chemical compatibility: Choose PTFE for its near-total chemical inertness, especially when working with strong acids, bases, or reactive organic solvents.

- If your primary focus is high-speed mixing or high viscosity: Choose stainless steel for its structural rigidity and ability to maintain shape and performance under high shear stress.

- If your primary focus is sterile or biological applications: Choose stainless steel for its non-porous surface and its proven compatibility with standard sterilization methods like autoclaving.

By understanding these core material properties, you can select an impeller that ensures the integrity and success of your experiment.

Summary Table:

| Material | Key Advantage | Key Limitation | Ideal For |

|---|---|---|---|

| PTFE | Unmatched chemical inertness | Lower strength and rigidity | Aggressive chemicals, non-stick needs |

| Stainless Steel | Superior strength and rigidity | Vulnerable to certain corrosives | High-speed, high-viscosity, sterile applications |

Struggling to choose the right impeller material for your specific application? The experts at KINTEK can help. We specialize in manufacturing high-precision PTFE components, including custom impellers, seals, and labware for the semiconductor, medical, and laboratory industries. Whether you need the ultimate chemical resistance of PTFE or are exploring other materials for demanding environments, our team can provide custom fabrication from prototypes to high-volume orders. Contact KINTEK today to discuss your requirements and ensure the integrity of your experiments.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications