The primary drawbacks of PEEK are its specific chemical vulnerabilities and its tendency to become brittle at low temperatures. While an exceptional high-performance polymer, it is not universally resistant and should not be used in environments with concentrated sulfuric or nitric acids, or in cryogenic applications where impact resistance is critical.

PEEK is a material defined by its exceptional strengths, but its limitations are absolute. Understanding its specific vulnerabilities to certain chemicals and its loss of ductility in the cold is not just a technical detail—it is the critical factor in preventing catastrophic application failure.

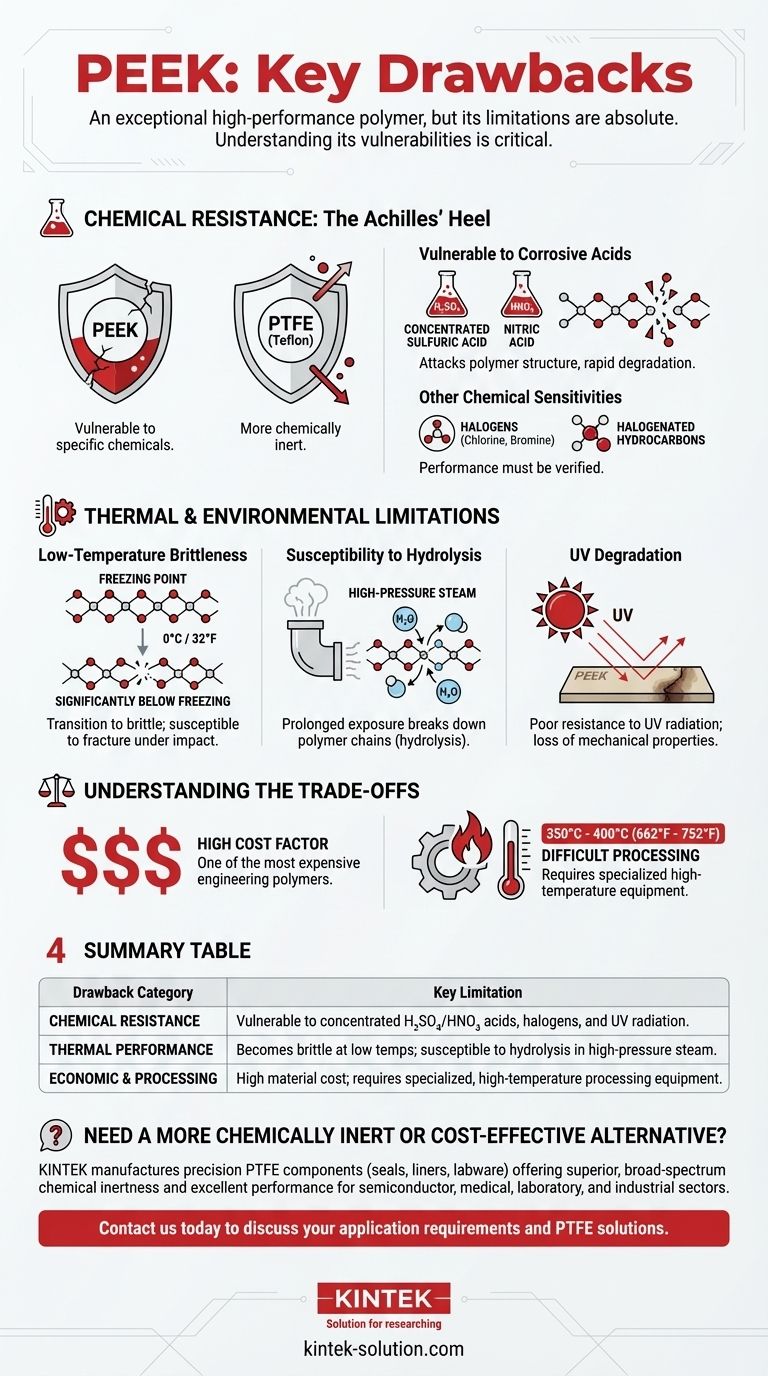

Chemical Resistance: The Achilles' Heel

While PEEK (Polyetheretherketone) offers excellent chemical resistance in many scenarios, it has clear, well-documented weaknesses that must be respected. Its performance is not as universally inert as some other fluoropolymers.

The PTFE Comparison

When benchmarked against materials like PTFE (Teflon), PEEK shows less overall chemical compatibility. PTFE is chemically inert to a much wider range of substances, making it a safer choice in environments with unknown or mixed chemical compositions.

Vulnerability to Corrosive Acids

PEEK should not be exposed to concentrated sulfuric acid or nitric acid. These aggressive oxidizing acids attack the polymer's chemical structure, leading to rapid degradation and failure.

Other Chemical Sensitivities

Beyond those specific acids, PEEK can also be attacked by halogens (like chlorine and bromine) and some halogenated hydrocarbons. The material's performance in any aggressive chemical environment must be verified before it is specified.

Thermal and Environmental Limitations

PEEK is famous for its high-temperature performance, but its behavior at the extremes of the temperature scale—both high and low—and in certain environments reveals key limitations.

Low-Temperature Brittleness

As temperatures drop significantly below freezing, PEEK undergoes a transition that makes it more brittle and less ductile. In cryogenic applications, this loss of ductility makes it susceptible to fracture under impact or load.

Susceptibility to Hydrolysis

While stable in boiling water, prolonged exposure to high-pressure steam can lead to hydrolysis, where water molecules break down the polymer chains. This is particularly true for unreinforced grades of PEEK.

UV Degradation

Standard, unfilled grades of PEEK have poor resistance to ultraviolet (UV) radiation. Sunlight exposure can cause a loss of mechanical properties and discoloration. For outdoor applications, carbon-filled or other UV-stabilized grades are essential.

Understanding the Trade-offs

Choosing PEEK involves balancing its premium performance against significant practical and economic considerations. Ignoring these trade-offs is a common source of project failure.

The High Cost Factor

PEEK is one of the most expensive engineering polymers on the market. Its cost can be an order of magnitude higher than other high-performance plastics. This premium is only justified when its unique combination of properties is absolutely necessary.

Difficult Processing Requirements

Processing PEEK requires extremely high temperatures, typically between 350°C and 400°C (662°F and 752°F). This necessitates specialized equipment for injection molding or extrusion, which can be a significant barrier for many processors.

Making the Right Choice for Your Application

To specify PEEK correctly, you must weigh its limitations against the primary demands of your project.

- If your primary focus is broad chemical inertness: PTFE is often the superior and safer choice, especially when dealing with aggressive acids or mixed chemical streams.

- If your primary focus is mechanical strength in a low-temperature environment: Be extremely cautious with PEEK due to its brittleness and consider materials specifically designed for cryogenic service.

- If your primary focus is an outdoor application: Do not use an unfilled grade of PEEK; you must specify a UV-stabilized grade, such as one filled with carbon fiber.

- If your primary focus is balancing performance and cost: Scrutinize whether a less expensive polymer like PEI (Ultem) or PSU could meet the requirements before committing to the high cost of PEEK.

Understanding these specific limitations is the key to successfully leveraging PEEK's exceptional strengths.

Summary Table:

| Drawback Category | Key Limitation |

|---|---|

| Chemical Resistance | Vulnerable to concentrated sulfuric/nitric acids, halogens, and UV radiation. |

| Thermal Performance | Becomes brittle at low temperatures; susceptible to hydrolysis in high-pressure steam. |

| Economic & Processing | High material cost; requires specialized, high-temperature processing equipment. |

Need a More Chemically Inert or Cost-Effective Alternative?

While PEEK has its place, its specific drawbacks in chemical resistance, low-temperature performance, and cost can be critical for demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

KINTEK manufactures precision PTFE components—including seals, liners, and labware—that offer superior, broad-spectrum chemical inertness and excellent performance across a wide temperature range. We provide custom fabrication from prototypes to high-volume orders, ensuring you get the right material for your specific needs without compromise.

Contact us today to discuss your application requirements and discover how our PTFE solutions can enhance your project's reliability and cost-efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection