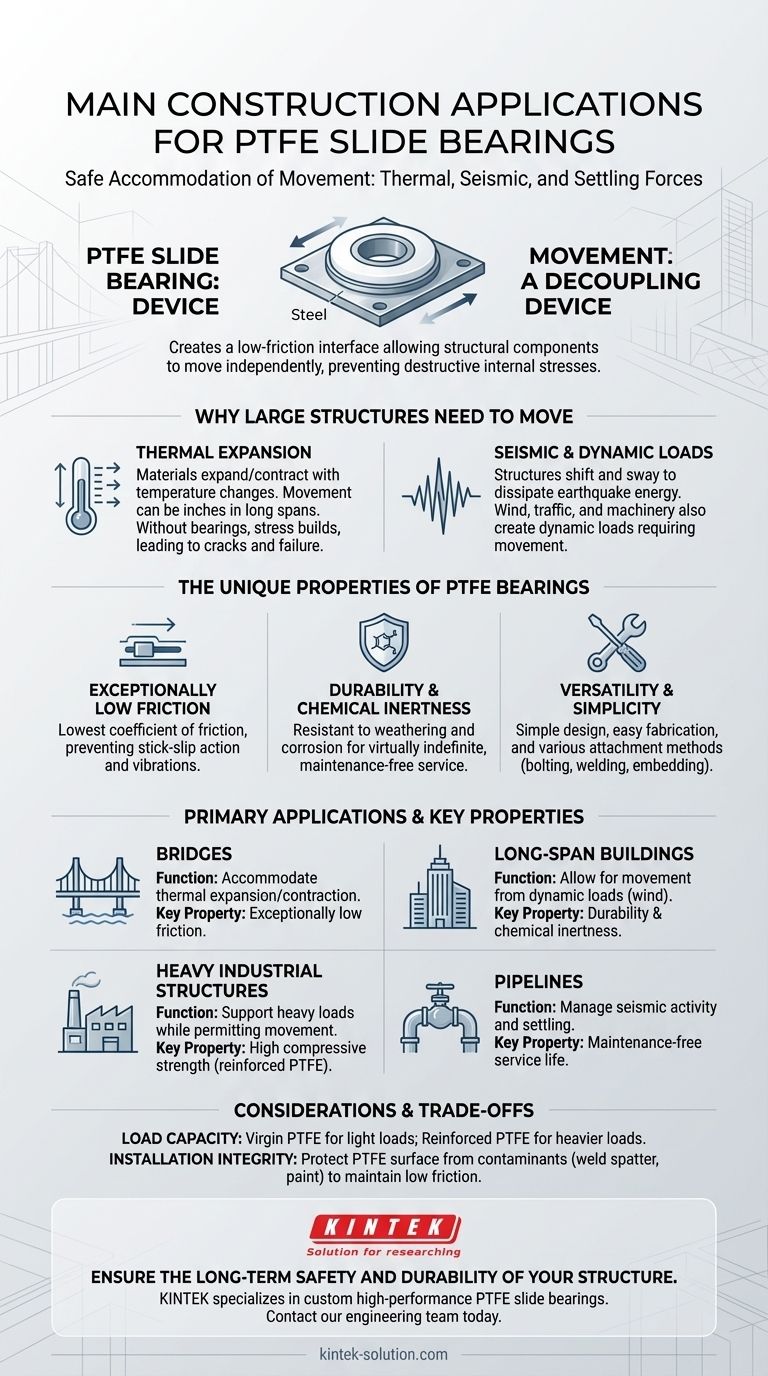

The primary construction applications for PTFE slide bearings are in bridges, long-span commercial buildings, heavy industrial structures, and pipelines. These components are engineered to safely accommodate movement caused by thermal expansion and contraction, seismic activity, and the settling of structural elements over time.

A PTFE slide bearing is fundamentally a decoupling device. It creates a low-friction interface that allows massive structural components to move independently, preventing the buildup of destructive internal stresses.

Why Large Structures Need to Move

Large-scale constructions are not static. They are constantly subjected to forces that cause them to expand, contract, and shift. A properly designed structure must accommodate this movement to maintain its integrity.

The Force of Thermal Expansion

As ambient temperatures change, construction materials like steel and concrete expand and contract. Over the long span of a bridge or a large roof, this movement can measure several inches.

Without a bearing to absorb this motion, immense stress would build up in columns, foundations, and beams, leading to cracks and potential failure.

Seismic and Dynamic Loads

In seismically active regions, structures must be able to shift and sway to dissipate the energy from an earthquake. Slide bearings provide a controlled plane of movement.

Similarly, forces from wind, traffic vibrations, or heavy machinery create dynamic loads that require structural elements to move without resistance.

The Unique Properties of PTFE Bearings

Polytetrafluoroethylene (PTFE) is uniquely suited for this role due to a combination of physical and chemical properties that make it an ideal bearing material.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This allows heavy structural elements to slide smoothly against each other.

This key property prevents stick-slip action, a jerky motion of sticking and releasing that can introduce damaging vibrations into a structure.

Durability and Chemical Inertness

PTFE is chemically inert and highly resistant to weathering and corrosion. This means the bearing will not degrade over time, even in harsh environments.

This durability leads to a virtually indefinite, maintenance-free service life, a critical advantage for inaccessible components inside a large structure.

Versatility and Simplicity

PTFE bearings are simple in design, making them cost-efficient to fabricate and install.

They can be attached through various methods, including bolting, welding, or embedding in mortar, allowing for flexible integration into steel and concrete constructions.

Understanding the Trade-offs and Considerations

While highly effective, the proper specification and installation of PTFE bearings are critical for their performance and longevity.

Load Capacity and Material Choice

Standard, or virgin PTFE, is ideal for lighter loads where minimal friction and chemical resistance are the primary requirements.

For heavier loads, such as those in major bridge supports, reinforced PTFE (often filled with glass fiber or other materials) is used. This increases compressive strength and wear resistance but may slightly alter the friction coefficient.

Installation Integrity is Paramount

The effectiveness of the bearing depends entirely on the integrity of the PTFE surface.

During construction, the surface must be meticulously protected from weld spatter, paint, and metal debris. Any contamination can compromise the low-friction interface and impede movement.

Making the Right Choice for Your Project

Selecting the appropriate bearing solution depends on the specific forces your structure must manage.

- If your primary focus is thermal expansion in long spans: A standard PTFE slide bearing offers the most cost-effective and reliable solution for predictable, slow-moving loads.

- If your primary focus is seismic performance or very heavy loads: Specify a reinforced PTFE bearing designed to handle high compressive forces and dynamic movement.

- If your primary focus is long-term durability and zero maintenance: The chemical inertness of PTFE makes it superior to mechanical or elastomeric alternatives, especially in corrosive or inaccessible locations.

Ultimately, incorporating PTFE slide bearings is a foundational strategy for ensuring the long-term safety and durability of any large-scale structure.

Summary Table:

| Application | Primary Function | Key PTFE Property Utilized |

|---|---|---|

| Bridges | Accommodate thermal expansion/contraction | Exceptionally low friction |

| Long-Span Buildings | Allow for movement from dynamic loads (wind, etc.) | Durability & chemical inertness |

| Heavy Industrial Structures | Support heavy loads while permitting movement | High compressive strength (reinforced PTFE) |

| Pipelines | Manage seismic activity and settling | Maintenance-free service life |

Ensure the Long-Term Safety and Durability of Your Structure

For construction projects in the semiconductor, medical, laboratory, and industrial sectors, the precision and reliability of your PTFE components are non-negotiable. KINTEK specializes in the custom fabrication of high-performance PTFE slide bearings, seals, liners, and labware.

We partner with you from prototype to high-volume production, ensuring every component meets the exacting demands for load capacity, low friction, and indefinite service life.

Contact our engineering team today to discuss your project's specific requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability