PTFE envelope gaskets provide a unique combination of benefits, centered on their exceptional chemical inertness and their ability to create a robust, adaptable mechanical seal. By encasing a compressible core material within a durable Polytetrafluoroethylene (PTFE) shell, they solve sealing challenges where both chemical resistance and mechanical performance are equally critical.

At its core, a PTFE envelope gasket is a hybrid solution. It leverages the chemical immunity and non-stick surface of a PTFE "envelope" while using a separate inner core material to provide the compressibility and resilience needed for a tight, reliable seal.

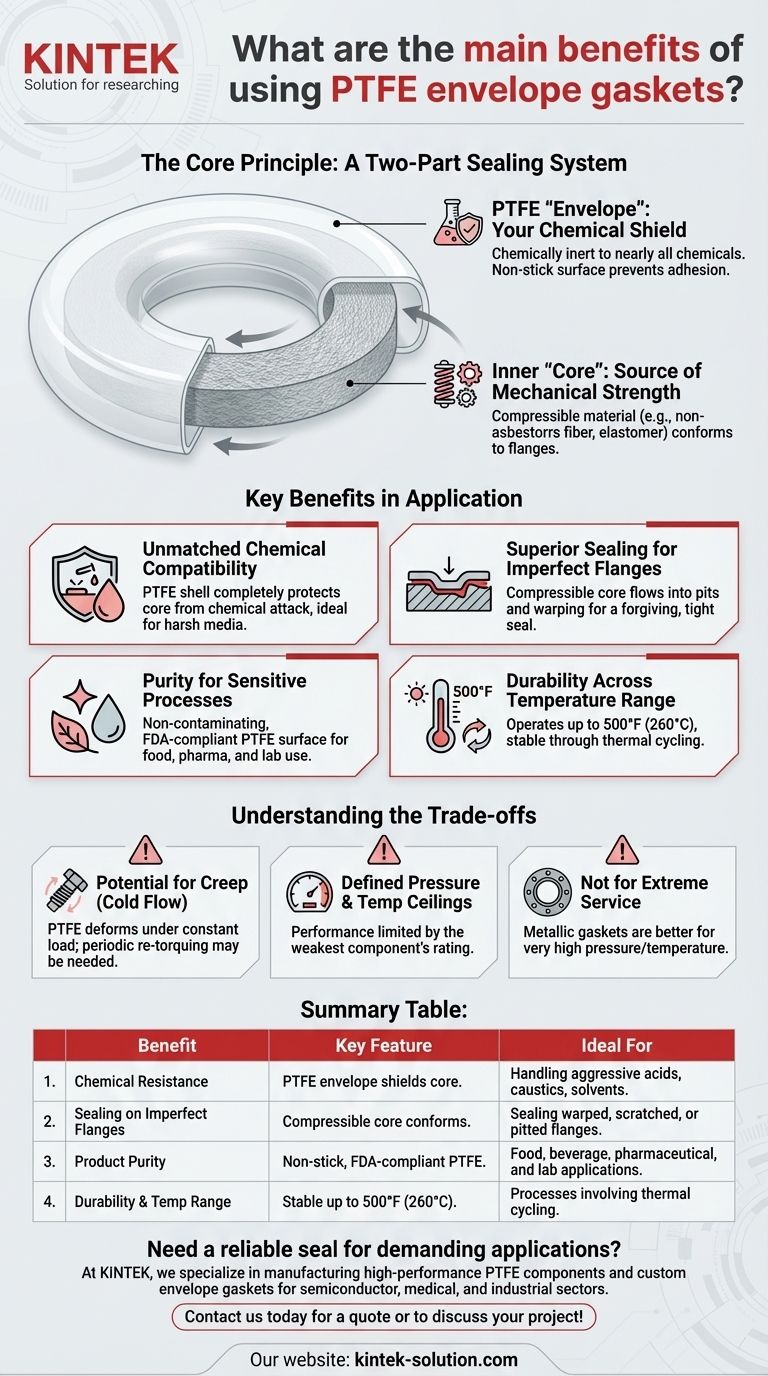

The Core Principle: A Two-Part Sealing System

To understand the benefits, you must first understand the design. It is not a single material but a clever combination of two distinct components working in tandem.

The PTFE "Envelope": Your Chemical Shield

The outer layer is made of pure PTFE, a fluoropolymer renowned for being chemically inert to nearly all industrial chemicals, acids, and caustics.

This envelope is the only surface exposed to the process media. Its non-stick properties also prevent material from adhering to the gasket, which is critical for ensuring product purity and simplifying flange cleaning.

The Inner "Core": The Source of Mechanical Strength

Inside the PTFE envelope sits a different material, chosen specifically for its mechanical properties like compressibility and recovery. This core allows the gasket to conform to flange imperfections and maintain a tight seal under bolt load.

Common core materials include compressed non-asbestos fiber or various elastomers (rubbers), each offering different levels of resilience and compression characteristics to suit the application.

Key Benefits in Application

This hybrid design delivers several distinct advantages over single-material gaskets.

Unmatched Chemical Compatibility

The PTFE shell completely protects the inner core material from chemical attack. This allows you to achieve a reliable seal in applications involving harsh media that would quickly degrade standard rubber or fiber gaskets.

Superior Sealing for Imperfect Flanges

The soft, compressible insert allows the gasket to flow into and fill minor pits, scratches, and warping on a flange face. This provides a more forgiving and reliable seal compared to rigid, solid PTFE gaskets which require near-perfect surfaces.

Purity for Sensitive Processes

Because PTFE is non-contaminating, odorless, and available in FDA-compliant grades, these gaskets are a primary choice for the food, beverage, and pharmaceutical industries. The non-stick surface ensures no gasket material leaches into the product stream.

Durability Across a Wide Temperature Range

PTFE envelope gaskets can typically operate in continuous temperatures up to 500°F (260°C), depending on the core material. This makes them a durable and stable choice for processes that experience significant thermal cycling.

Understanding the Trade-offs

No sealing solution is perfect for every scenario. To use these gaskets effectively, you must be aware of their limitations.

Potential for Creep (Cold Flow)

While the design mitigates it, PTFE has a natural tendency to "creep" or slowly deform over time when under a constant compressive load. This can lead to a loss of bolt torque. The inner core provides resistance, but periodic bolt re-torquing may be necessary in critical applications.

Defined Pressure and Temperature Ceilings

The gasket's overall performance is limited by its weakest component. The PTFE envelope has a maximum temperature limit, and the inner core has a maximum pressure rating. Exceeding either of these specifications can lead to premature seal failure.

Not Ideal for Extreme Service

For very high-pressure and high-temperature services, metallic or semi-metallic gaskets (like spiral wound gaskets) are often a more robust choice. Envelope gaskets excel in the space between standard soft gaskets and heavy-duty metallic seals.

Making the Right Choice for Your Application

Use these guidelines to determine if a PTFE envelope gasket is the correct solution for your specific goal.

- If your primary focus is handling aggressive chemicals: PTFE envelope gaskets are a premier choice, effectively shielding a compressible core from corrosive media.

- If your primary focus is ensuring product purity: The non-contaminating, non-stick PTFE surface makes this an ideal and often FDA-compliant sealing solution for food, beverage, or pharmaceutical lines.

- If your primary focus is sealing warped or uneven flanges: The combination of a soft core and durable shell provides excellent conformability for a reliable seal where rigid gaskets might fail.

- If your primary focus is very high pressure or temperature: You should likely consider a spiral wound or other semi-metallic gasket, as an envelope gasket may be outside its optimal service range.

Ultimately, the PTFE envelope gasket excels as a specialized solution that intelligently combines material properties to solve complex sealing problems.

Summary Table:

| Benefit | Key Feature | Ideal For |

|---|---|---|

| Chemical Resistance | PTFE envelope shields the core from corrosive media. | Handling aggressive acids, caustics, and solvents. |

| Sealing on Imperfect Flanges | Compressible core conforms to surface irregularities. | Sealing warped, scratched, or pitted flanges. |

| Product Purity | Non-stick, non-contaminating, FDA-compliant PTFE surface. | Food, beverage, pharmaceutical, and laboratory applications. |

| Durability & Temperature Range | Stable performance across a wide temperature range (up to 500°F/260°C). | Processes involving thermal cycling. |

Need a reliable seal for demanding applications?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom envelope gaskets. Our precision production ensures a perfect fit and reliable performance for the semiconductor, medical, laboratory, and industrial sectors.

We can fabricate from prototypes to high-volume orders to meet your exact specifications. Let our expertise solve your complex sealing challenges.

Contact us today for a quote or to discuss your project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications