The primary advantages of using Polytetrafluoroethylene (PTFE) in manufacturing are its exceptional chemical inertness, extremely low coefficient offriction, and high heat resistance. These core properties translate directly into manufacturing components that last longer, require less maintenance, and improve the overall efficiency and reliability of production processes.

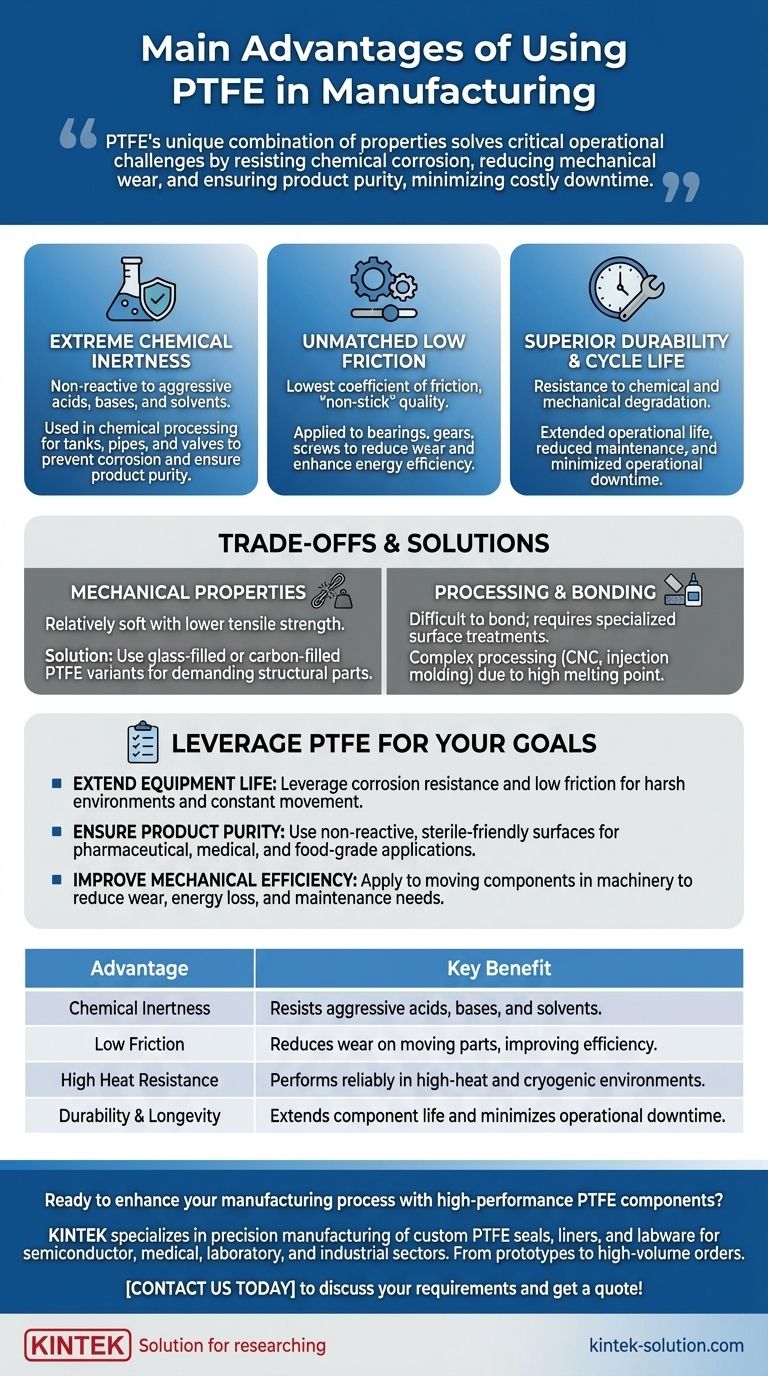

PTFE's true value in manufacturing is not just one feature, but its unique combination of properties. It solves critical operational challenges by simultaneously resisting chemical corrosion, reducing mechanical wear, and ensuring product purity, which ultimately minimizes costly downtime.

The Core Properties Driving PTFE's Value

PTFE's benefits stem from a few foundational characteristics that make it uniquely suited for demanding industrial environments. Understanding these properties is key to leveraging the material effectively.

Extreme Chemical Inertness

PTFE is one of the most non-reactive materials known. It can withstand aggressive acids, bases, and solvents that would degrade most other materials.

This property is critical in chemical processing, where it's used to line tanks, pipes, and valves, preventing equipment corrosion and ensuring the purity of the chemicals being handled.

In pharmaceutical and medical manufacturing, this inertness prevents any unwanted chemical interactions, guaranteeing product safety and contamination-free processes.

Unmatched Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "non-stick" quality is fundamental to its performance.

When applied as a coating to moving parts like bearings, gears, or screws, it drastically reduces friction and wear. This leads to a longer lifespan for components and greater energy efficiency.

In automotive applications, this can improve engine efficiency by minimizing friction between parts, and enhance brake systems by reducing the wear that leads to performance issues.

Superior Durability and Cycle Life

Components made from or coated with PTFE exhibit a remarkably long operational life. This durability is a direct result of its resistance to both chemical and mechanical degradation.

For example, PTFE diaphragm valves have a high cycle life, meaning they can operate for far longer than valves made from other materials before needing maintenance or replacement.

This longevity is a significant economic advantage, as it reduces the need for replacement parts, minimizes maintenance labor, and, most importantly, reduces operational downtime.

High Thermal and Biological Resistance

PTFE maintains its properties over a wide range of temperatures, making it suitable for both high-heat and cryogenic applications.

Furthermore, its smooth, non-porous surface naturally resists microbial growth. This makes it an ideal choice for sterile environments in food processing and medical device manufacturing.

Understanding the Trade-offs

While its advantages are significant, PTFE is not a universal solution. Acknowledging its limitations is crucial for proper application.

Mechanical Properties

Standard PTFE is a relatively soft material with lower tensile strength and creep resistance compared to other engineering plastics. This can make it unsuitable for high-load structural applications.

To overcome this, manufacturers often use glass-filled or carbon-filled PTFE variants. These composites offer superior mechanical properties and are used for more demanding parts like medical implants and aerospace components.

Processing and Bonding

PTFE's chemical inertness also makes it very difficult to bond to other materials using conventional adhesives. Specialized surface treatments are often required to achieve a durable bond.

It can be processed using methods like CNC machining and injection molding, but its high melting point and specific processing requirements can make manufacturing more complex than with other polymers.

How to Leverage PTFE for Your Goals

Your choice to use PTFE should be driven by the specific problem you are trying to solve.

- If your primary focus is extending equipment life: Leverage PTFE's corrosion resistance and low-friction properties in coatings and linings for parts exposed to harsh chemicals or constant movement.

- If your primary focus is ensuring product purity: Its non-reactive and sterile-friendly surface makes it the ideal choice for any equipment in pharmaceutical, medical, or food-grade applications.

- If your primary focus is improving mechanical efficiency: Apply PTFE to moving components in engines, pumps, and other machinery to reduce wear, minimize energy loss, and decrease maintenance needs.

Ultimately, incorporating PTFE is a strategic decision to build greater resilience and efficiency into demanding manufacturing systems.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Chemical Inertness | Resists aggressive acids, bases, and solvents. |

| Low Friction | Reduces wear on moving parts, improving efficiency. |

| High Heat Resistance | Performs reliably in both high-heat and cryogenic environments. |

| Durability & Longevity | Extends component life and minimizes operational downtime. |

Ready to enhance your manufacturing process with high-performance PTFE components?

KINTEK specializes in precision manufacturing of custom PTFE seals, liners, labware, and more for the semiconductor, medical, laboratory, and industrial sectors. We deliver solutions that improve equipment longevity, ensure product purity, and boost operational efficiency—from prototypes to high-volume orders.

Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications