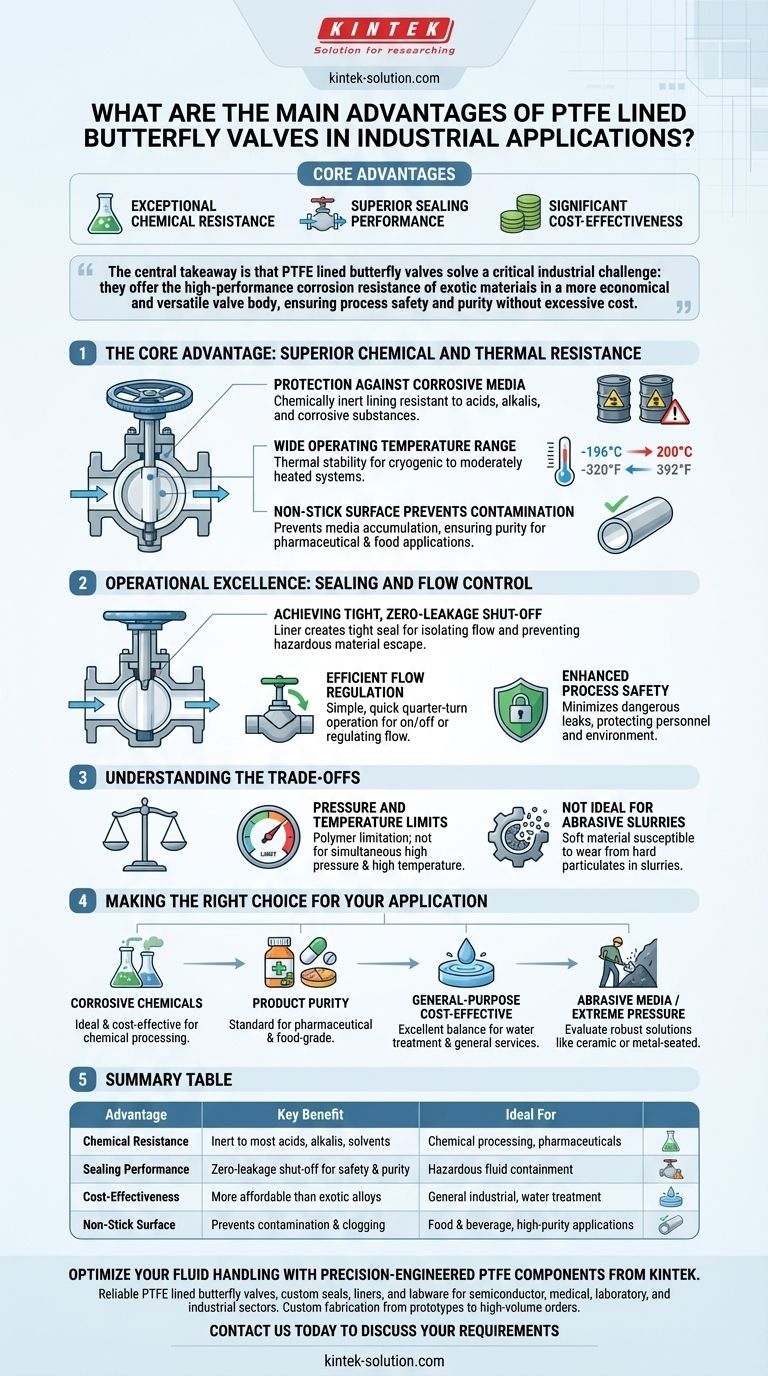

At their core, the main advantages of PTFE lined butterfly valves are exceptional chemical resistance, superior sealing performance, and significant cost-effectiveness. These valves provide a durable and reliable solution for controlling the flow of corrosive or high-purity fluids in a compact, lightweight design that often outperforms more expensive alloy alternatives.

The central takeaway is that PTFE lined butterfly valves solve a critical industrial challenge: they offer the high-performance corrosion resistance of exotic materials in a more economical and versatile valve body, ensuring process safety and purity without excessive cost.

The Core Advantage: Superior Chemical and Thermal Resistance

The primary reason engineers specify PTFE lined valves is the material's inherent ability to withstand aggressive environments that would quickly destroy standard valves.

Protection Against Corrosive Media

The PTFE (polytetrafluoroethylene) lining is chemically inert, making it resistant to a vast range of acids, alkalis, and other corrosive substances.

This makes the valve suitable for the most demanding applications in chemical processing, where it reliably handles toxic or highly aggressive media.

Wide Operating Temperature Range

PTFE linings maintain their integrity across a broad spectrum of temperatures, with a typical operating range from -196°C to 200°C (-320°F to 392°F).

This thermal stability allows for versatility in processes that involve significant temperature fluctuations, from cryogenic applications to moderately heated systems.

Non-Stick Surface Prevents Contamination

PTFE is famous for its non-stick properties, similar to coatings used on cookware.

In an industrial setting, this prevents media from accumulating on valve surfaces. This is critical for ensuring product purity in pharmaceutical or food and beverage applications and prevents clogging in other processes.

Operational Excellence: Sealing and Flow Control

Beyond material resistance, these valves are engineered for high-performance operation, directly impacting plant efficiency and safety.

Achieving Tight, Zero-Leakage Shut-off

The design of PTFE lined butterfly valves provides exceptional sealing capabilities, often achieving a "zero-leakage" standard.

The liner creates a tight seal around the disc edge, which is essential for isolating flow and preventing the escape of hazardous or valuable materials.

Efficient Flow Regulation

These valves are effective for both simple on/off isolation and for regulating (throttling) the flow of fluids.

Their quarter-turn operation is simple and quick, allowing for rapid response whether operated manually or with an actuator.

Enhanced Process Safety

By combining a corrosion-proof lining with a tight shut-off, these valves significantly enhance plant safety. They minimize the risk of dangerous leaks, protecting both personnel and the environment from exposure to hazardous chemicals.

Understanding the Trade-offs

While highly effective, PTFE lined valves are not a universal solution. Understanding their limitations is key to proper application.

Pressure and Temperature Limits

Although the temperature range is wide, PTFE is a polymer, not metal. It has pressure-temperature limitations. In applications with simultaneous high pressure and high temperature, a metal-seated valve may be required.

Not Ideal for Abrasive Slurries

PTFE is a relatively soft material. It can be susceptible to damage from highly abrasive media, such as slurries containing hard particulates, which can wear down the liner and compromise the seal over time.

Making the Right Choice for Your Application

Selecting the correct valve depends entirely on the specific demands of your process.

- If your primary focus is handling corrosive chemicals: The chemical inertness of the PTFE liner makes this valve an ideal and cost-effective choice.

- If your primary focus is ensuring product purity: The non-stick, non-contaminating surface is the key benefit, making it a standard in pharmaceutical and food-grade applications.

- If your primary focus is a general-purpose, cost-effective solution: This valve provides an excellent balance of performance and price for water treatment and general chemical services.

- If your process involves abrasive media or extreme pressure/temperature: You should evaluate more robust solutions, such as ceramic-lined or high-performance metal-seated butterfly valves.

Ultimately, a PTFE lined butterfly valve provides an exceptional balance of chemical inertness, reliable sealing, and economic value for a vast range of industrial processes.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Chemical Resistance | Inert to most acids, alkalis, and solvents | Chemical processing, pharmaceuticals |

| Sealing Performance | Zero-leakage shut-off for safety and purity | Hazardous fluid containment |

| Cost-Effectiveness | More affordable than exotic alloy alternatives | General industrial, water treatment |

| Non-Stick Surface | Prevents contamination and clogging | Food & beverage, high-purity applications |

Optimize your fluid handling with precision-engineered PTFE components from KINTEK.

Whether you need reliable PTFE lined butterfly valves, custom seals, liners, or labware, KINTEK delivers solutions tailored for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the precise performance and corrosion resistance your application demands.

Contact us today to discuss your specific requirements and discover how our PTFE solutions can enhance your process safety, purity, and cost-efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability