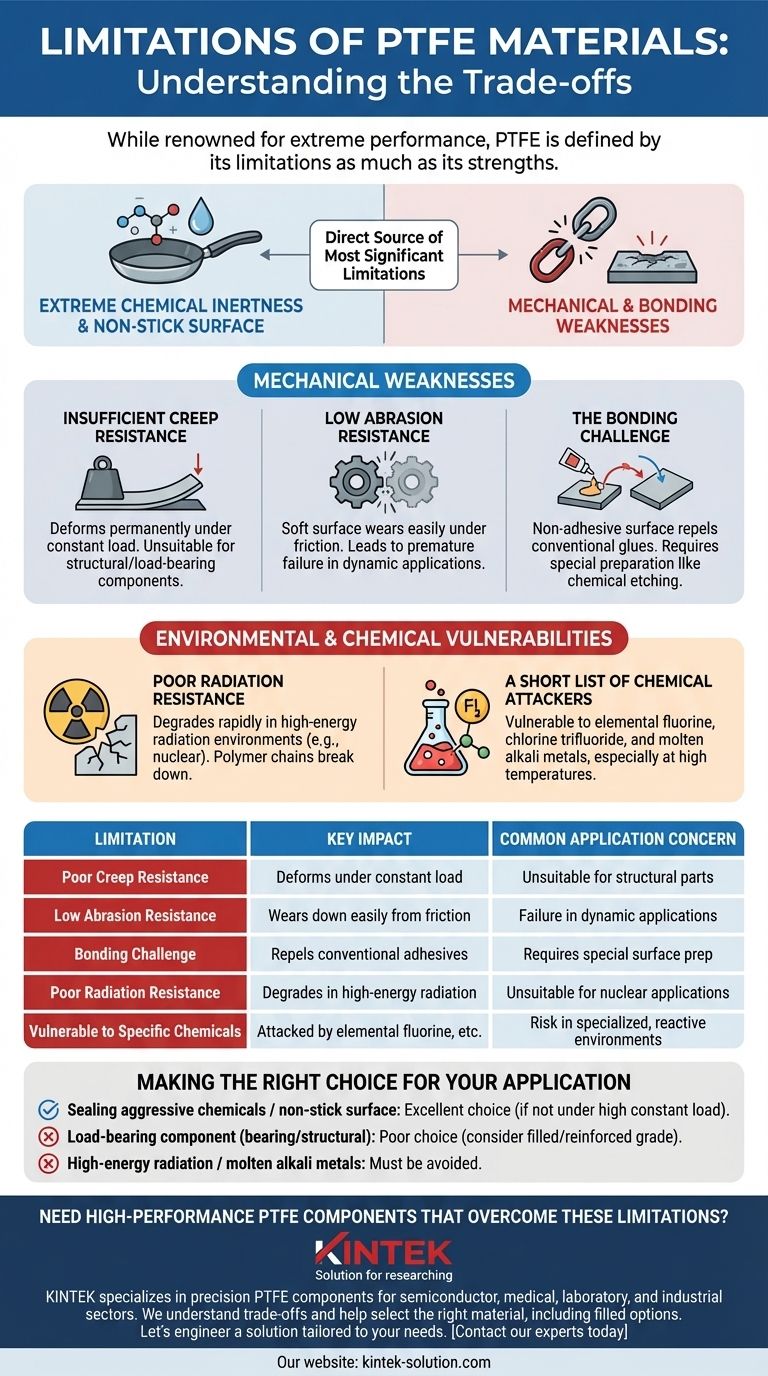

While Polytetrafluoroethylene (PTFE) is renowned for its extreme performance, it is defined as much by its limitations as its strengths. The primary drawbacks of pure PTFE are its poor mechanical properties, specifically its low resistance to creep and abrasion, its inability to be easily bonded to other materials, and its vulnerability to high-energy radiation and a few highly reactive chemicals.

PTFE’s most celebrated characteristics—its extreme chemical inertness and non-stick surface—are the direct source of its most significant limitations. Understanding this fundamental trade-off is the key to using the material correctly.

The Mechanical Weaknesses of PTFE

While exceptionally stable, the molecular structure of PTFE results in a material that is mechanically soft and prone to deformation.

Insufficient Creep Resistance

Creep is the tendency of a solid material to deform permanently under the influence of a constant mechanical load.

Pure PTFE has poor creep resistance, meaning it will slowly change shape over time if a load is applied. This makes it unsuitable for structural or load-bearing components that must maintain precise dimensions.

Low Abrasion Resistance

The famous low-friction surface of PTFE is also relatively soft.

This softness means pure PTFE wears down easily when subjected to friction and abrasion. This can lead to premature failure in dynamic applications like shaft bearings unless the PTFE is reinforced with fillers.

The Bonding Challenge

PTFE is one of the most difficult polymers to bond using conventional adhesives.

Its non-adhesive surface, a result of its extreme chemical inertness, repels virtually all glues. Special surface preparation techniques, like chemical etching, are required to create a bondable surface.

Environmental and Chemical Vulnerabilities

Although known for its incredible resilience, PTFE has specific environmental conditions where it will degrade.

Poor Radiation Resistance

PTFE is not a suitable material for environments with high-energy radiation, such as nuclear applications.

This type of radiation causes the long polymer chains of PTFE to break down, leading to a rapid loss of its mechanical properties and material failure.

A Short List of Chemical Attackers

While resistant to nearly all acids, solvents, and bases, PTFE is vulnerable to a very specific set of chemicals.

Extremely reactive agents like elemental fluorine, chlorine trifluoride, and molten alkali metals can attack PTFE, especially at high temperatures and pressures. However, these are highly specialized and rare conditions.

Understanding the Trade-offs

The limitations of PTFE are not arbitrary flaws; they are the inherent flip side of its greatest strengths.

The Inertness vs. Bonding Paradox

The same low surface energy that makes PTFE impervious to aggressive chemicals also makes it repel adhesives. You cannot have its world-class chemical resistance without also getting its non-stick, non-bondable surface.

The Low-Friction vs. Wear-Resistance Dilemma

The molecules in PTFE slide past each other with very little resistance, creating its signature slipperiness. This same molecular mobility, however, means the material is soft and can be easily worn away by abrasive forces.

The Temperature Range Reality

PTFE's wide operating temperature range is impressive, but its mechanical weaknesses become more pronounced at the upper end of that range. As it gets hotter, its tendency to creep under load increases significantly. It can survive the heat, but its structural integrity diminishes.

Making the Right Choice for Your Application

To use PTFE effectively, you must align its specific profile with the demands of your project.

- If your primary focus is sealing aggressive chemicals or creating a non-stick surface: PTFE is an excellent choice, provided the part is not under a high, constant mechanical load.

- If your primary focus is a load-bearing component like a bearing or structural part: Pure PTFE is a poor choice due to creep and wear; you must consider a filled/reinforced grade of PTFE or a different polymer entirely.

- If your application involves high-energy radiation or molten alkali metals: PTFE must be avoided as it will quickly degrade and fail.

Choosing the right material means understanding its complete profile, and with PTFE, its limitations are just as important as its strengths.

Summary Table:

| Limitation | Key Impact | Common Application Concern |

|---|---|---|

| Poor Creep Resistance | Deforms under constant load | Unsuitable for structural/load-bearing parts |

| Low Abrasion Resistance | Wears down easily from friction | Failure in dynamic applications (e.g., bearings) |

| Bonding Challenge | Repels conventional adhesives | Requires special surface preparation for assembly |

| Poor Radiation Resistance | Degrades in high-energy radiation | Unsuitable for nuclear applications |

| Vulnerable to Specific Chemicals | Attacked by elemental fluorine, etc. | Risk in highly specialized, reactive environments |

Need High-Performance PTFE Components That Overcome These Limitations?

At KINTEK, we specialize in manufacturing precision PTFE components (seals, liners, labware, and more) for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical trade-offs of PTFE and can help you select the right material grade—including filled and reinforced options—or design custom fabrications from prototypes to high-volume orders to ensure your application's success.

Let's engineer a solution tailored to your specific needs. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments